Pass Six Sigma Yellow Belt Certification Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

LSSYB Premium Bundle

- Premium File 150 Questions & Answers. Last update: Feb 15, 2026

- Training Course 84 Video Lectures

- Study Guide 382 Pages

LSSYB Premium Bundle

- Premium File 150 Questions & Answers

Last update: Feb 15, 2026 - Training Course 84 Video Lectures

- Study Guide 382 Pages

Purchase Individually

Premium File

Training Course

Study Guide

LSSYB Exam - Lean Six Sigma Yellow Belt

| Download Free LSSYB Exam Questions |

|---|

Six Sigma Six Sigma Yellow Belt Certification Practice Test Questions and Answers, Six Sigma Six Sigma Yellow Belt Certification Exam Dumps

All Six Sigma Six Sigma Yellow Belt certification exam dumps, study guide, training courses are prepared by industry experts. Six Sigma Six Sigma Yellow Belt certification practice test questions and answers, exam dumps, study guide and training courses help candidates to study and pass hassle-free!

Foundations of Six Sigma and the Yellow Belt's Role

Six Sigma represents a disciplined, data-driven approach and methodology for eliminating defects in any process, from manufacturing to transactional and from product to service. The fundamental objective of Six Sigma is to implement a measurement-based strategy that focuses on process improvement and variation reduction. It achieves this through the application of a comprehensive set of quality management methods, including a heavy emphasis on statistical analysis. The ultimate goal is to reach a state where processes produce fewer than 3.4 defects per million opportunities (DPMO), which is considered near-perfect quality.

This philosophy is not merely a quality control program but a broader business management strategy. It seeks to drive organizational transformation by focusing on customer requirements and using facts and data to solve problems. By systematically identifying and removing the causes of errors and minimizing variability in business processes, Six Sigma helps organizations enhance their performance, increase profits, boost employee morale, and improve the quality of their products or services. It provides a framework that allows companies to make decisions based on verifiable data and statistical methods rather than on assumptions or guesswork, leading to more sustainable and impactful improvements.

The Historical Origins of Six Sigma

The journey of Six Sigma began in the 1980s at Motorola, an American telecommunications company. An engineer named Bill Smith, now widely regarded as the "Father of Six Sigma," developed the methodology as a response to the company's struggles with product quality and the high costs associated with warranty claims. Motorola's leadership recognized that traditional quality control methods, which often focused on detecting defects after they occurred, were insufficient. They needed a proactive approach to prevent defects from happening in the first place by improving process capability and reducing variability.

This new methodology was built upon the foundations of earlier quality improvement theories from pioneers like Shewhart, Deming, Juran, and Crosby. It integrated concepts such as statistical process control (SPC), design of experiments, and a focus on continuous improvement. Motorola's success with this approach was remarkable, reportedly saving the company billions of dollars and earning it the prestigious Malcolm Baldrige National Quality Award in 1988. This success did not go unnoticed, and in the 1990s, Six Sigma gained widespread prominence when it was adopted by General Electric's CEO, Jack Welch, as a central business strategy, cementing its reputation as a powerful tool for corporate transformation.

Core Principles Driving Six Sigma Success

At the heart of the Six Sigma methodology are several core principles that guide its implementation. The primary focus is always on the customer. Understanding and meeting customer expectations is paramount, as the customer's perception of quality is the ultimate measure of success. This involves diligently collecting customer feedback and translating their needs into measurable requirements for products and services. Another key principle is the use of data and statistical analysis to drive decisions. Six Sigma replaces intuition and speculation with a fact-based approach, ensuring that solutions are targeted at the true root causes of problems.

Furthermore, Six Sigma is a proactive methodology. It seeks to identify and address potential issues before they result in defects, rather than simply reacting to problems after they occur. This is achieved through a deep understanding and management of processes. By mapping, measuring, and analyzing business processes, practitioners can identify sources of variation and inefficiency. This leads to a culture of continuous improvement, where the pursuit of perfection is an ongoing journey, not a final destination. Finally, Six Sigma requires strong leadership commitment and engagement from all levels of an organization to foster a collaborative environment focused on achieving excellence.

Understanding the Six Sigma Belt System

The structure of Six Sigma implementation within an organization is often organized using a belt-ranking system, inspired by martial arts. This hierarchy denotes different levels of training, expertise, and responsibility. At the top are Master Black Belts, who are seasoned experts responsible for mentoring Black Belts, managing strategic Six Sigma programs, and providing technical leadership. They are the organization's in-house consultants and champions of the methodology. Below them are the Black Belts, who are full-time project leaders. They manage complex, cross-functional improvement projects and are highly proficient in advanced statistical analysis and project management.

Green Belts are employees who have received Six Sigma training and dedicate a portion of their time to process improvement projects, often under the guidance of a Black Belt. They lead smaller-scale projects within their own functional areas and are instrumental in collecting data and implementing solutions. The entry point into this system is the Yellow Belt. Yellow Belts are team members who have a basic understanding of Six Sigma concepts. They support Green and Black Belt projects by participating in data collection, process mapping, and helping to implement changes. This tiered structure ensures that expertise is distributed effectively throughout the organization.

The Specific Role of a Six Sigma Yellow Belt

A Six Sigma Yellow Belt is a professional who is versed in the foundational elements of the Six Sigma methodology. While they do not lead large-scale projects like their Green or Black Belt counterparts, their role is crucial for the successful integration of a quality-focused culture at the ground level. Yellow Belts often act as the subject matter experts for their specific job functions within a larger project team. They provide valuable insights into the day-to-day operations of a process, helping to identify practical challenges and opportunities for improvement that might otherwise be overlooked by those less familiar with the details.

Their primary responsibility is to support improvement projects led by Green Belts and Black Belts. This support can take many forms, including participating in brainstorming sessions to identify potential causes of problems, collecting data to measure process performance, helping to create process maps, and assisting in the implementation of new procedures. In addition, Yellow Belts are often empowered to lead smaller, localized improvement efforts using simpler frameworks like the Plan-Do-Check-Act (PDCA) cycle. This allows them to make a direct impact in their immediate work environment, fostering a sense of ownership and continuous improvement throughout the workforce.

Differentiating DMAIC and DMADV

Within the Six Sigma framework, there are two primary methodologies used to drive improvements: DMAIC and DMADV. DMAIC, which stands for Define, Measure, Analyze, Improve, and Control, is the most common methodology. It is used to improve an existing business process that is falling below the desired standard of performance. The focus of DMAIC is on identifying the root causes of problems in a current process and implementing solutions to enhance its efficiency and effectiveness. Yellow Belts are most commonly involved in DMAIC projects, supporting the various activities within each of its five phases.

In contrast, DMADV, which stands for Define, Measure, Analyze, Design, and Verify, is used when an organization needs to create a new process, product, or service from scratch. It is also applied when an existing process is so flawed that it requires a complete redesign rather than incremental improvement. The "Design" and "Verify" phases replace the "Improve" and "Control" phases of DMAIC, focusing on designing a new process that meets customer needs and verifying that the design performs as intended. While Yellow Belts are less frequently involved in the complexities of DMADV projects, understanding its purpose is part of a complete foundational knowledge of Six Sigma.

The Importance of Process Variation

A central concept in Six Sigma, and one that Yellow Belts must grasp, is the idea of process variation. Variation refers to the natural differences that occur in the output of any process. For example, the time it takes to process a customer order will not be exactly the same every single time; there will be slight variations. While some variation is inherent and unavoidable, excessive variation is the primary enemy of quality. It makes process outcomes unpredictable and is the leading cause of defects, errors, and customer dissatisfaction. A process with high variation is unreliable and difficult to manage.

Six Sigma provides the tools to measure, understand, and ultimately reduce this variation. The goal is to make processes as consistent and predictable as possible. By reducing variation, a company can ensure that its products or services consistently meet customer specifications and quality standards. For a Yellow Belt, this means learning how to identify potential sources of variation in their daily tasks. They contribute by following standardized procedures precisely and by helping to collect data that allows Green and Black Belts to perform statistical analysis to pinpoint the key factors that are causing inconsistency in the process.

Defining the Equation Y = f(x)

A foundational concept that encapsulates the Six Sigma approach is the equation Y = f(x). This simple mathematical expression represents a profound way of thinking about business processes. In this equation, 'Y' represents the outcome or result of a process, which is often a key performance indicator (KPI) that the organization wants to improve. This could be customer satisfaction, product defects, or delivery time. 'Y' is the effect, the dependent variable that we are trying to control. The letter 'f' represents the function or the process itself.

The 'x' represents the various inputs, factors, and variables that go into the process and influence the final outcome. These are the independent variables, the potential causes. The core idea of Six Sigma is that if you want to improve the output (Y), you cannot do so by focusing on 'Y' directly. Instead, you must identify the critical few inputs (the 'x' variables) that have the most significant impact on the outcome. By understanding and controlling these vital 'x's, you can effectively control and predict the 'Y'. A Yellow Belt's role often involves helping to identify these potential 'x' factors and gathering data on them for further analysis.

The Plan-Do-Check-Act (PDCA) Cycle

While DMAIC is the cornerstone methodology for large Six Sigma projects, Yellow Belts are often heavily involved with a simpler but equally powerful framework known as the Plan-Do-Check-Act (PDCA) cycle. Also called the Deming Cycle, PDCA is an iterative four-stage model for carrying out change. It is ideal for managing smaller, localized improvement initiatives that Yellow Belts might lead. The first stage, 'Plan,' involves identifying a problem or opportunity for improvement and developing a hypothesis or a plan for making a change.

The 'Do' stage involves implementing the plan on a small scale, essentially running a test or pilot of the proposed change. During the 'Check' stage, data is collected and analyzed to see if the change had the desired effect. This step is crucial for verifying whether the improvement was successful. Finally, the 'Act' stage involves taking action based on the results from the check phase. If the change was successful, it is implemented on a broader scale and standardized. If not, the cycle begins again with a new plan. This iterative approach allows for rapid learning and continuous improvement at all levels of an organization.

Fostering a Culture of Continuous Improvement

The ultimate success of a Six Sigma deployment goes beyond the completion of individual projects. It lies in the ability to create a sustainable culture of continuous improvement. This means embedding the principles of quality and data-driven decision-making into the very fabric of the organization. Yellow Belts play a vital role in this cultural transformation. As frontline employees who are trained in the basics of Six Sigma, they act as ambassadors for the methodology in their daily work. They help to bridge the gap between high-level strategic initiatives and the operational realities of the workforce.

By participating in projects and leading their own small-scale improvements, Yellow Belts demonstrate the value of the Six Sigma approach to their peers. They help to break down resistance to change by showing that new processes are not just top-down mandates but are developed with input from the people who actually do the work. Their involvement helps to build momentum and ensures that the mindset of looking for better ways to do things becomes a shared responsibility rather than the sole domain of a few dedicated experts. This grassroots involvement is essential for making quality a part of everyone's job.

Overview of the DMAIC Methodology

The DMAIC framework is the heart of the Six Sigma approach for improving existing processes. It is a systematic, five-phase, data-driven cycle designed to solve problems and enhance performance. The acronym stands for Define, Measure, Analyze, Improve, and Control. Each phase has a specific set of goals and involves the use of particular tools and techniques. The structured nature of DMAIC ensures that teams address problems thoroughly, moving from identifying an issue to implementing a lasting solution in a logical sequence. It prevents teams from jumping to conclusions or implementing solutions that do not address the actual root cause of the problem.

For a Six Sigma Yellow Belt, understanding the purpose and flow of the DMAIC process is fundamental. While a Green or Black Belt will lead the project and handle the more complex statistical analyses, the Yellow Belt is a critical team member who provides essential support throughout each phase. Their involvement ensures that the project team is grounded in the practical realities of the process being studied. By learning the objectives of each phase, a Yellow Belt can contribute meaningfully, whether by helping to define the problem, collecting accurate data, brainstorming potential causes, or helping to test and implement new procedures.

The Define Phase: Setting the Foundation

The Define phase is the first and arguably most critical step in any DMAIC project. The primary goal of this phase is to clearly articulate the business problem, the project goals, the scope, and the customer requirements. If this phase is not executed properly, the entire project can be misguided. A key output from this phase is the project charter, a formal document that provides a clear and concise summary of the project. It acts as an agreement between the project team and the organization's leadership, outlining what the team is expected to accomplish.

A Yellow Belt's contribution to the Define phase is invaluable. They often participate in developing the problem statement, ensuring it accurately reflects the issues they experience in their daily work. They can help identify key stakeholders, including colleagues, supervisors, and other departments that might be affected by the project. Furthermore, Yellow Belts are instrumental in creating a high-level process map, often using a tool called SIPOC, which stands for Suppliers, Inputs, Process, Outputs, and Customers. This tool provides a simple but comprehensive view of the process, helping to establish clear boundaries and scope for the project from the outset.

Key Tools in the Define Phase

Several tools are commonly used during the Define phase to ensure the project starts on solid footing. The project charter is the most important document, capturing the business case, problem statement, project scope, goals, timeline, and team members. It is a living document that guides the team throughout the project lifecycle. Another critical tool is the Voice of the Customer (VOC). This involves systematically gathering and analyzing customer feedback through surveys, interviews, or focus groups to understand their needs and expectations. These needs are then translated into specific, measurable requirements known as Critical to Quality (CTQ) characteristics.

Yellow Belts are often directly involved in VOC activities, as they may have frequent interactions with internal or external customers. They can provide anecdotal evidence of common customer complaints or issues, which can then be validated with more formal data collection. They also contribute significantly to process mapping. Creating a high-level SIPOC diagram helps the team visualize the entire process at a glance, clarifying who the suppliers and customers are, what inputs are required, and what outputs are produced. This initial mapping is essential for defining the scope and preventing the project from becoming too broad and unmanageable.

The Measure Phase: Quantifying the Problem

Once the project is clearly defined, the team moves into the Measure phase. The primary objective here is to collect data to establish a baseline performance for the process and to begin narrowing down the list of potential causes of the problem. This phase is all about understanding the current state of the process in objective, quantifiable terms. It involves developing a data collection plan, defining what needs to be measured, and ensuring that the measurement system itself is accurate and reliable. Without good data, the subsequent phases of the project will be based on guesswork.

Yellow Belts are the foot soldiers of the Measure phase. Their role is often hands-on, involving the direct collection of data from the process. This could mean using check sheets to tally the occurrence of errors, timing process steps with a stopwatch, or pulling reports from a software system. Their familiarity with the process makes them ideal candidates for this task, as they understand the practical nuances of data collection. They might also assist in what is known as a Measurement System Analysis (MSA) to verify that the data being collected is consistent and trustworthy, ensuring the integrity of the project's foundation.

The Analyze Phase: Identifying the Root Cause

With reliable data in hand, the team enters the Analyze phase. The goal of this phase is to use the data collected to identify, validate, and prioritize the root causes of the problem. This is where the team moves from observing symptoms to uncovering the underlying disease. The Analyze phase involves using a combination of graphical and statistical tools to sift through the data, identify patterns, and test hypotheses about what is causing the process to underperform. The aim is to distinguish between the trivial many causes and the vital few root causes that are responsible for the majority of the problem.

Yellow Belts play a crucial role in the qualitative analysis that takes place during this phase. They are active participants in brainstorming sessions, using their process knowledge to help generate a comprehensive list of potential causes. They frequently use tools like the fishbone diagram, also known as the Ishikawa or cause-and-effect diagram, to organize these potential causes into logical categories. They also contribute to creating more detailed process maps to pinpoint bottlenecks or areas of inefficiency. Through techniques like the 5 Whys, where the question "why?" is asked repeatedly, Yellow Belts help the team drill down from a surface-level problem to its fundamental origin.

The Improve Phase: Developing and Testing Solutions

After identifying the root causes in the Analyze phase, the team transitions to the Improve phase. The objective here is to brainstorm, evaluate, and implement solutions that directly address the validated root causes. This is the phase where creative thinking and practical problem-solving come to the forefront. The team generates a range of potential solutions and then uses criteria such as cost, effort, and potential impact to select the most promising ones for implementation. Often, these solutions are first tested on a small scale through a pilot program to assess their effectiveness before a full-scale rollout.

Yellow Belts are essential during the Improve phase because of their practical understanding of the workflow. They can provide a reality check on proposed solutions, identifying potential unintended consequences or implementation challenges. They are often involved in the pilot tests of new procedures, providing valuable feedback on what works and what does not. Their participation helps to ensure that the solutions developed are not just theoretically sound but are also practical and sustainable in the day-to-day work environment. They may also help in developing new standard operating procedures and training materials for the improved process.

The Control Phase: Sustaining the Gains

The final phase of the DMAIC cycle is the Control phase. The purpose of this phase is to ensure that the improvements made are sustained over the long term and that the process does not revert to its old, inefficient ways. This involves creating a monitoring plan, updating documentation, and establishing a system for ongoing process management. The Control phase is about locking in the gains and ensuring that the project delivers lasting benefits to the organization. A solution is not truly successful until it has been proven to be stable and sustainable over time.

The role of the Yellow Belt in the Control phase is to help embed the new process into the daily routine. They are often the first to use the new standardized work procedures and can act as coaches or mentors for their colleagues, helping them to adopt the new way of working. They may be responsible for collecting data for the ongoing monitoring plan, using tools like control charts or process dashboards to track the performance of the improved process. Their vigilance in following the new procedures and their role in monitoring performance are critical for preventing backsliding and for making the improvements a permanent part of the organization's operations.

The Interconnectivity of the DMAIC Phases

It is important to understand that the DMAIC phases are not isolated silos. They are interconnected parts of a continuous cycle of improvement. The output of one phase serves as the direct input for the next. For example, the clear problem statement and scope from the Define phase guide what is measured in the Measure phase. The data from the Measure phase is the raw material for the Analyze phase. The root causes identified in the Analyze phase are the targets for the solutions developed in the Improve phase. Finally, the solutions from the Improve phase are what need to be sustained in the Control phase.

This logical flow ensures a rigorous and thorough approach to problem-solving. Rushing through or skipping a phase can jeopardize the entire project. For a Yellow Belt, recognizing this interconnectivity helps them understand the importance of their contributions at each stage. A well-defined problem statement makes data collection easier. Accurate data leads to a more precise root cause analysis. A correctly identified root cause leads to a more effective solution. And a practical solution is easier to control and sustain. Every step builds upon the last, leading to a robust and lasting improvement.

Yellow Belt's Contribution to Project Documentation

Throughout the DMAIC project, thorough documentation is essential. It serves as a record of the team's activities, findings, and decisions. This documentation is crucial for communicating progress to stakeholders, for training purposes, and for ensuring that the knowledge gained during the project is retained by the organization. Key documents include the project charter, data collection plans, process maps, analysis results, implementation plans, and control plans. This creates a detailed story of the project, from the initial problem to the final, sustained solution.

A Yellow Belt often assists in the creation and maintenance of this documentation. They might be responsible for updating process maps as the team's understanding of the process evolves. They may help record the minutes and action items from team meetings. They can also contribute to the development of new standard operating procedures (SOPs) or job aids that reflect the improved process. By participating in the documentation process, Yellow Belts gain a deeper understanding of the project's journey and help to create a valuable asset that can be used to guide future improvement efforts within the organization.

Adapting DMAIC for Different Environments

While DMAIC originated in manufacturing, its principles are universally applicable. The framework is flexible and can be adapted to improve processes in virtually any industry, including healthcare, finance, information technology, logistics, and customer service. The specific tools used and the type of data collected may vary, but the logical five-phase progression remains the same. In a hospital, a DMAIC project might focus on reducing patient wait times. In a bank, it could be used to improve the accuracy of loan applications. In an IT department, it might target the reduction of system downtime.

For a Yellow Belt, this adaptability means that the skills they learn are highly transferable. Understanding the DMAIC framework provides them with a structured problem-solving method that they can apply in various contexts throughout their career. Whether the "defect" is a manufacturing flaw, a billing error, a late delivery, or a software bug, the DMAIC cycle provides a reliable roadmap for investigating the problem, identifying its root cause, and implementing a sustainable solution. This versatility is one of the key reasons why Six Sigma skills are so highly valued by employers across a wide range of sectors.

The Seven Basic Tools of Quality

The Seven Basic Tools of Quality are a set of graphical and statistical techniques that are fundamental to process improvement. These tools were first emphasized by Kaoru Ishikawa, a Japanese quality control pioneer, and are designed to be simple enough for anyone in an organization to use, regardless of their statistical training. For a Six Sigma Yellow Belt, proficiency with these tools is essential as they form the backbone of many activities within a DMAIC project. They provide a common language and a systematic way to collect, analyze, and interpret data, making them indispensable for effective problem-solving at the grassroots level.

The seven tools include the cause-and-effect diagram, check sheet, control chart, histogram, Pareto chart, scatter diagram, and flowchart. Each tool serves a different purpose, from organizing ideas to analyzing data patterns. Their power lies in their simplicity and visual nature, which makes complex information easier to understand and communicate. Yellow Belts frequently use these tools to support project teams, whether it's by brainstorming potential causes, tallying defects, or mapping out a process. Mastering these foundational tools is a key step in a Yellow Belt's journey toward becoming an effective contributor to quality initiatives.

Process Mapping and Flowcharts

A flowchart, or process map, is a visual representation of the sequence of steps and decisions in a process. It is one of the most fundamental and widely used tools in Six Sigma. Creating a process map helps a team to gain a shared understanding of how a process actually works, rather than how it is supposed to work. This often reveals unnecessary steps, bottlenecks, and areas of complexity that are prime candidates for improvement. For a Yellow Belt, process mapping is a critical skill. They are often the subject matter experts who can provide the most accurate details about the steps involved in their daily tasks.

There are different levels of process maps, from a high-level SIPOC diagram used in the Define phase to a detailed, step-by-step flowchart used in the Analyze phase. Yellow Belts are heavily involved in creating these detailed maps. By walking through the process step-by-step and documenting each action and decision point, they help the project team identify sources of waste, delay, and potential errors. This visual tool is invaluable for pinpointing exactly where a problem is occurring within a complex workflow, making it a starting point for almost any improvement effort.

Cause-and-Effect (Fishbone) Diagram

The cause-and-effect diagram, also known as the Ishikawa or fishbone diagram, is a powerful brainstorming tool used to explore all the potential causes of a specific problem or effect. The diagram's structure resembles the skeleton of a fish, with the "head" representing the problem statement and the "bones" representing different categories of potential causes. Common categories used in manufacturing include the 6 Ms: Manpower, Method, Machine, Material, Measurement, and Mother Nature (Environment). In service industries, categories might include People, Process, Policies, and Plant/Technology.

Yellow Belts are key participants in the brainstorming sessions where these diagrams are created. During the Analyze phase of a DMAIC project, the team gathers to generate ideas about what could be causing the problem. The fishbone diagram provides a structured way to capture and organize these ideas. A Yellow Belt's hands-on experience with the process allows them to contribute practical and insightful suggestions for potential causes that might not be obvious to others. The completed diagram serves as a visual map of all possible root causes, which the team can then investigate further using data.

Check Sheets and Data Collection

A check sheet is a simple, structured form used to collect and tally data in real-time at the location where the data is generated. It is a fundamental tool used in the Measure phase of a DMAIC project. Unlike a blank piece of paper, a check sheet is designed to make data collection easy, efficient, and less prone to errors. It can be used to record the frequency of different types of defects, the occurrence of specific events, or other observable data. The design of the check sheet is tailored to the specific data being collected, often with predefined categories to make tallying straightforward.

The task of using check sheets often falls to Yellow Belts. Because they are directly involved in the process, they are in the best position to collect accurate, real-time data. For example, a Yellow Belt working in a call center might use a check sheet to track the number and types of customer complaints received each day. This simple act of systematic data collection provides the raw material that the project team needs to begin their analysis. It transforms anecdotal evidence and opinions into hard facts, which is a core principle of the Six Sigma methodology.

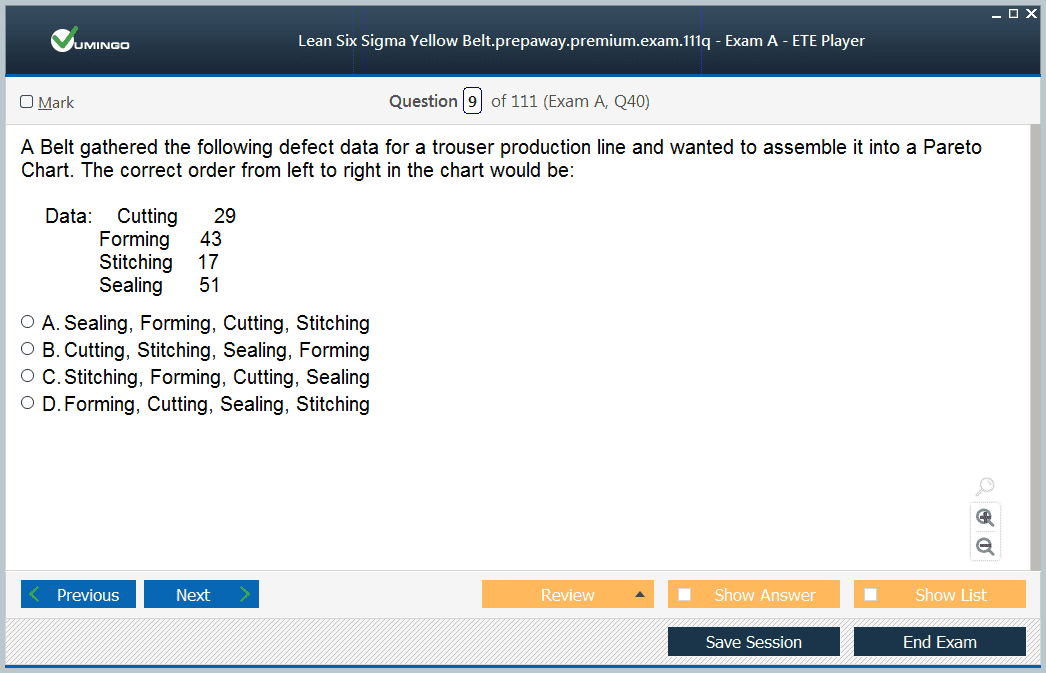

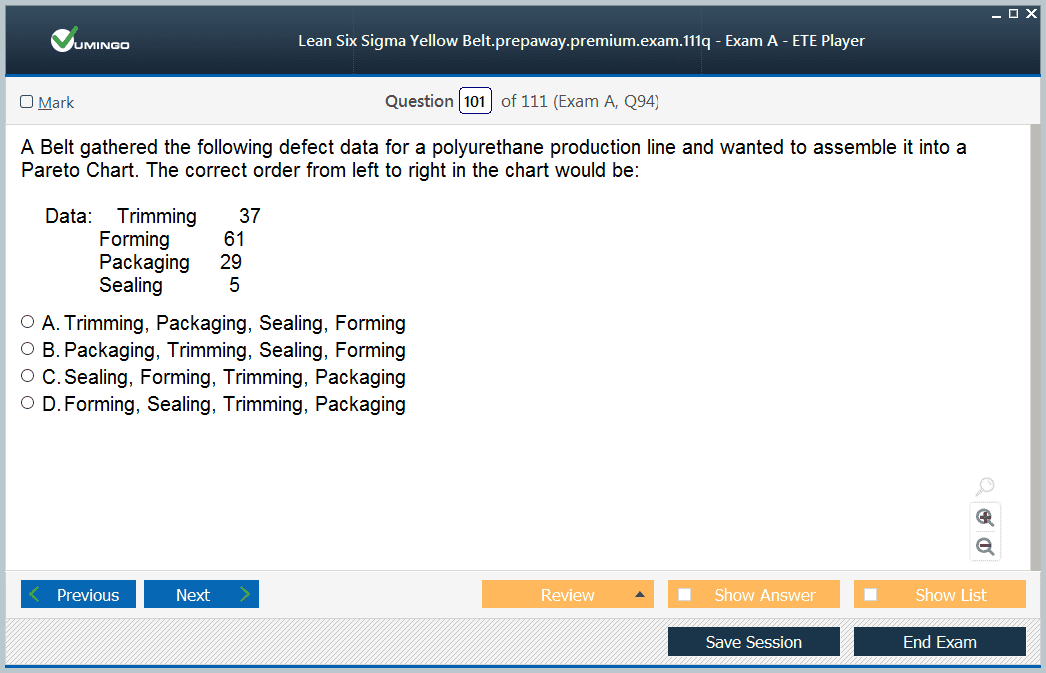

Pareto Charts for Prioritization

A Pareto chart is a special type of bar chart where the values are plotted in descending order of frequency or impact, and a cumulative percentage line is also displayed. The chart is based on the Pareto principle, also known as the 80/20 rule, which suggests that for many events, roughly 80% of the effects come from 20% of the causes. In a quality improvement context, this means that a small number of defect types will typically account for the majority of the problems. A Pareto chart is used in the Analyze phase to visually separate these "vital few" problems from the "trivial many."

Yellow Belts can assist in creating and interpreting Pareto charts. After data has been collected using a check sheet, it can be organized to build the chart. The resulting visual makes it immediately clear where the team should focus its improvement efforts. For instance, a Pareto chart of customer complaints might show that out of ten different complaint types, the top two account for 75% of all complaints. This allows the team to prioritize their resources on solving the problems that will have the greatest impact, rather than wasting time on minor issues.

Histograms to Understand Distribution

A histogram is a graphical representation of the distribution of numerical data. It is a bar chart that shows the frequency of data points falling within specified ranges or "bins." Histograms are used in the Measure and Analyze phases to understand the shape and spread of process data. By looking at a histogram, a team can quickly get a sense of the process's central tendency (the average), its variability (how spread out the data is), and its overall distribution shape. It can reveal whether the process is centered on its target, whether it is stable, and whether there are any unusual patterns or outliers.

While the statistical interpretation of a histogram might be led by a Green or Black Belt, a Yellow Belt can be involved in collecting the data that is used to create it. For example, they might measure the cycle time for a specific task over a period of weeks. This data can then be plotted in a histogram to visualize the distribution of cycle times. This visual summary is often more intuitive and revealing than looking at a raw list of numbers, and it helps the team to understand the nature of the process variation they are trying to reduce.

The 5 Whys Technique for Root Cause Analysis

The 5 Whys is a simple but surprisingly effective interrogative technique used to explore the cause-and-effect relationships underlying a particular problem. The primary goal is to determine the root cause of a defect or problem by repeatedly asking the question "Why?". Each answer forms the basis of the next question. While it is called the "5" Whys, the actual number of iterations can vary; the key is to continue asking "why" until the fundamental, actionable root cause has been identified, which is often when a flawed process or policy is discovered.

This technique is perfectly suited for Yellow Belts and is often used in conjunction with the fishbone diagram during the Analyze phase. For example, if the problem is "The customer invoice was incorrect," the first "why" might be "Because the wrong pricing was used." The next "why" could be "Why was the wrong pricing used?" and the answer might be "Because the sales representative used an outdated price list." By continuing this line of questioning, the team can move beyond blaming individuals and uncover the systemic issues that allowed the error to occur, leading to a much more effective and permanent solution.

Introduction to Statistical Process Control (SPC)

Statistical Process Control (SPC) is a method of quality control that employs statistical methods to monitor and control a process. The goal of SPC is to ensure that a process operates at its full potential to produce conforming products or services. A key tool in SPC is the control chart, which is a graph used to study how a process changes over time. Data are plotted in time order, and the chart has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. These lines are determined from historical data.

While the creation and advanced interpretation of control charts are typically Green or Black Belt responsibilities, Yellow Belts need to have a basic understanding of their purpose. They are often the ones who collect the data that is plotted on the charts in the Control phase of a DMAIC project. They need to understand the difference between common cause variation, which is inherent to the process, and special cause variation, which is signaled by points falling outside the control limits and indicates an external, often correctable, issue. This knowledge helps them to monitor the health of a process and to alert the team when it may be going out of control.

Brainstorming and Idea Generation

Brainstorming is a group creativity technique by which efforts are made to find a conclusion for a specific problem by gathering a list of ideas spontaneously contributed by its members. It is a fundamental activity used throughout the DMAIC cycle, but it is particularly prominent in the Analyze phase for generating potential root causes and in the Improve phase for developing potential solutions. Effective brainstorming encourages open thinking and discourages criticism of ideas, creating an environment where innovative and practical solutions can emerge.

Yellow Belts are vital participants in brainstorming sessions. Their proximity to the process gives them a unique perspective and allows them to contribute ideas that are grounded in reality. There are various brainstorming techniques, such as structured (round-robin) brainstorming, where each person contributes an idea in turn, and unstructured (free-form) brainstorming. A facilitator, often a Green or Black Belt, guides the session, but the quality of the output depends on the active participation of all team members, including the Yellow Belts, who bring their valuable subject matter expertise to the table.

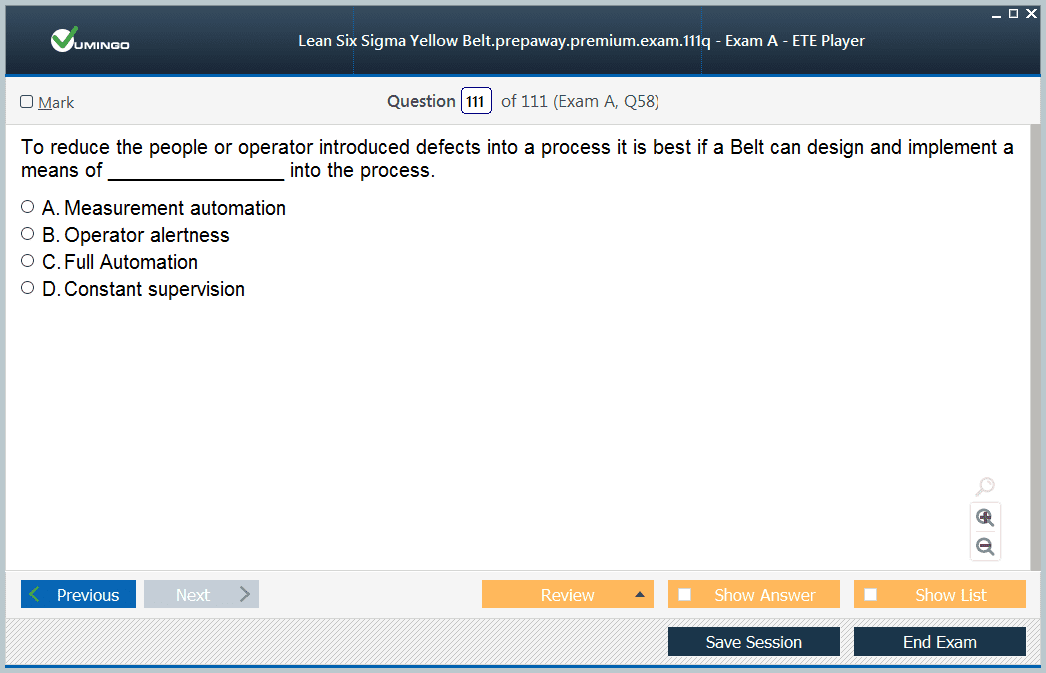

The Value of Standardized Work

Standardized work is the practice of establishing and documenting the best, safest, and most efficient method for performing a particular task or process. It is a cornerstone of a stable and predictable operation. By ensuring that every operator performs the task in the same way every time, standardized work dramatically reduces process variation, which is a primary goal of Six Sigma. It provides a baseline for performance, making it easier to identify deviations and opportunities for further improvement. Without standardization, it is impossible to sustain the gains achieved through a DMAIC project.

In the Control phase, Yellow Belts are instrumental in both creating and adhering to standardized work. They may help to write the new standard operating procedures (SOPs) or work instructions based on the solutions developed in the Improve phase. More importantly, they are responsible for following these new standards diligently in their daily work and for coaching their peers to do the same. This discipline at the operational level is what ensures that the improved process remains in a state of control and continues to deliver the desired results long after the project team has disbanded.

The Yellow Belt as a Project Team Member

The primary function of a Six Sigma Yellow Belt is to serve as an effective member of a process improvement project team. These projects are typically led by a Green Belt or Black Belt, who relies heavily on the support and expertise of the Yellow Belt members. A Yellow Belt is not just a passive participant; they are an active contributor who brings a wealth of knowledge about the specific process being studied. They are the eyes and ears of the project on the ground floor, providing a crucial link between the project leadership and the frontline workforce.

Their role on the team is multifaceted. They participate in team meetings, contribute to brainstorming sessions, and take on specific tasks related to the project's objectives. Their involvement ensures that the project remains focused on practical and achievable outcomes. The presence of trained Yellow Belts on a project team also helps to build buy-in and acceptance for the proposed changes among their peers. When colleagues see that one of their own is involved in developing the solution, they are more likely to embrace the new process, which is critical for successful implementation and long-term sustainability.

Specific Day-to-Day Responsibilities

On a day-to-day basis, a Yellow Belt's responsibilities are integrated with their regular job functions but with an added focus on quality and process improvement. They are expected to be champions of the Six Sigma mindset in their immediate work area. A key responsibility is data collection. As part of a DMAIC project, they may be tasked with gathering performance data using check sheets, timers, or other measurement tools. This requires diligence and a commitment to accuracy, as the quality of the data directly impacts the validity of the project's conclusions.

Another common responsibility is process observation and mapping. A Yellow Belt might spend time meticulously documenting the steps of a process, identifying any variations or deviations from the standard procedure. They are also often involved in implementing small-scale changes and experiments as part of the Improve phase. After a project is complete, they play a crucial role in monitoring the improved process, using control charts or checklists to ensure it remains stable and continues to meet performance targets. These tasks are vital for the success of any process improvement initiative.

Leading Small-Scale Improvement Projects

While Yellow Belts typically support larger projects led by Green or Black Belts, they are also frequently empowered to lead their own smaller, localized improvement initiatives. These projects are usually focused on issues within their direct control or within their immediate team. For these smaller projects, the full DMAIC methodology may be too rigorous. Instead, Yellow Belts often utilize the more streamlined Plan-Do-Check-Act (PDCA) cycle. This framework allows them to quickly identify a problem, implement a test solution, check the results, and then act to standardize the improvement or try a new approach.

Leading these small projects provides Yellow Belts with valuable hands-on experience in project management and problem-solving. It allows them to apply their Six Sigma training in a practical setting, building their confidence and competence. These small wins can have a significant cumulative impact on the organization's performance. They also help to foster a powerful culture of continuous improvement, where every employee feels empowered to make a positive change in their work environment, rather than waiting for a large, formal project to address every issue. This bottom-up approach to improvement is a key benefit of having a well-trained Yellow Belt workforce.

Boosting Your Resume and Career Prospects

In today's competitive job market, employers are constantly seeking candidates who can bring more than just a basic skill set to the table. A Six Sigma Yellow Belt certification on a resume is a clear indicator to a potential employer of a candidate's commitment to quality, efficiency, and continuous improvement. It demonstrates an understanding of a structured, data-driven methodology for problem-solving. This is a highly valuable trait in any industry, as all organizations are looking for ways to reduce waste, improve processes, and increase customer satisfaction.

Even at an entry level, the certification sets a candidate apart from their peers. It shows that they have invested in their professional development and possess a foundational knowledge of business process improvement. Including the certification on professional networking profiles can also increase visibility to recruiters who are specifically searching for candidates with quality management skills. It signals that the individual is not just focused on performing their assigned tasks but is also capable of thinking critically about how to perform those tasks better, making them a more attractive and valuable asset to any team.

Potential for Increased Salary and Value

While a Yellow Belt certification alone may not automatically trigger a significant salary increase, it undeniably enhances an employee's value to their organization. This increased value can translate into greater opportunities for advancement and, consequently, higher earning potential over time. Employers value employees who can contribute to cost-saving and efficiency-improving initiatives. A certified Yellow Belt is equipped with the tools and mindset to identify waste and suggest practical improvements, which can have a direct positive impact on the company's bottom line.

As an employee demonstrates their ability to apply Six Sigma principles successfully, they become a more indispensable part of the team. This can lead to increased responsibilities, selection for high-profile projects, and consideration for promotion. The salary data from major job aggregation platforms suggests a positive correlation between Six Sigma certification and compensation. Professionals with these skills are often in high demand, and companies are willing to invest in individuals who can help drive operational excellence. The certification is a stepping stone that opens doors to more challenging and rewarding roles.

The Career Path: From Yellow to Green and Black Belt

For many professionals, the Six Sigma Yellow Belt certification is the first step on a rewarding career path in quality management and process improvement. It provides the foundational knowledge upon which more advanced skills can be built. After gaining practical experience as a Yellow Belt and participating in several projects, an individual may choose to pursue a Green Belt certification. This next level of training involves more in-depth statistical analysis and project management skills, preparing the individual to lead their own small to medium-sized DMAIC projects.

From Green Belt, the path can lead to becoming a Black Belt. Black Belts are full-time process improvement experts who tackle an organization's most complex and critical business problems. They possess a deep mastery of advanced statistical tools and act as mentors and coaches for Green and Yellow Belts. The progression through the belt levels corresponds with increasing levels of expertise, responsibility, and influence within the organization. Starting with a Yellow Belt provides a solid and accessible entry point into this structured and highly respected career trajectory.

Applicability Across Various Industries

One of the greatest strengths of the Six Sigma methodology is its versatility. The principles of reducing variation, eliminating waste, and focusing on the customer are not limited to manufacturing. This means that a Yellow Belt certification is a valuable credential in a wide array of industries. In healthcare, a Yellow Belt might work on a project to reduce patient wait times or improve the accuracy of medical billing. In the financial sector, they could help streamline the loan approval process or reduce errors in transaction processing.

In information technology, a Yellow Belt might contribute to a project aimed at improving software development cycles or reducing the number of help desk tickets. In logistics and supply chain management, they could focus on optimizing inventory levels or improving on-time delivery rates. The common thread across all these examples is the focus on improving a process to achieve better outcomes. Because every organization is made up of processes, the skills of a Six Sigma Yellow Belt are universally applicable and in high demand across the entire economy.

Job Roles for Certified Yellow Belts

A Six Sigma Yellow Belt certification can enhance a professional's qualifications for a variety of job roles. It is not a standalone job title but rather a credential that complements an existing position or opens doors to new ones where a quality focus is required. Common roles where Yellow Belt skills are highly valued include Business Process Analyst, Quality Assurance Specialist, Operations Manager, and Supply Chain Coordinator. In these positions, the ability to map processes, collect data, and identify improvement opportunities is a core competency.

Other roles that benefit from this certification include Project Coordinator, Manufacturing Engineer, Customer Service Supervisor, and IT Support Analyst. In essence, any role that involves managing or executing a process can be performed more effectively by someone with Six Sigma training. The certification demonstrates a proactive approach to problem-solving and a commitment to operational excellence that is attractive to employers filling these types of positions. It provides a practical toolkit that can be applied immediately to add value in a wide range of professional contexts.

Interpersonal Skills and Team Collaboration

Beyond the technical tools and methodologies, being an effective Six Sigma Yellow Belt requires strong interpersonal and collaboration skills. Process improvement is fundamentally a team sport. A Yellow Belt must be able to communicate clearly and effectively with their fellow team members, project leaders, and colleagues. They need to be good listeners, capable of understanding different perspectives and contributing constructively to group discussions. The ability to work collaboratively is essential for the success of any project.

Yellow Belts often act as a bridge between the technical project team and the frontline employees. This requires them to be able to explain concepts and changes in a way that is easy to understand and non-threatening. They need to be adept at building consensus and encouraging participation from their peers. Skills in conflict resolution and negotiation can also be valuable, as process changes can sometimes be met with resistance. The combination of technical knowledge from their Six Sigma training and strong soft skills makes a Yellow Belt a truly effective agent of positive change within an organization.

Continuing Education and Lifelong Learning

Achieving a Six Sigma Yellow Belt certification should be viewed not as a final destination but as the beginning of a journey of lifelong learning. The fields of quality management and process improvement are constantly evolving, with new tools, techniques, and technologies emerging. To remain effective, professionals must stay current with these developments. Many certifying bodies offer resources for continuing education, and there are numerous books, articles, and online courses available to help practitioners deepen their knowledge.

For a Yellow Belt, this might involve learning more about a specific quality tool, exploring Lean principles that complement Six Sigma, or seeking out opportunities to participate in more complex projects to gain broader experience. The mindset of continuous improvement that is at the heart of Six Sigma should also be applied to one's own personal and professional development. By continuously seeking to learn and grow, a Yellow Belt can increase their value to their organization and advance their career in the exciting and impactful field of operational excellence.

Six Sigma Yellow Belt certification practice test questions and answers, training course, study guide are uploaded in ETE files format by real users. Study and pass Six Sigma Six Sigma Yellow Belt certification exam dumps & practice test questions and answers are the best available resource to help students pass at the first attempt.