- Home

- Six Sigma Certifications

- LSSWB Lean Six Sigma White Belt Dumps

Pass Six Sigma LSSWB Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

LSSWB Premium Bundle

- Premium File 171 Questions & Answers. Last update: Feb 22, 2026

- Training Course 53 Video Lectures

Last Week Results!

Includes question types found on the actual exam such as drag and drop, simulation, type-in and fill-in-the-blank.

Based on real-life scenarios similar to those encountered in the exam, allowing you to learn by working with real equipment.

All Six Sigma LSSWB certification exam dumps, study guide, training courses are Prepared by industry experts. PrepAway's ETE files povide the LSSWB Lean Six Sigma White Belt practice test questions and answers & exam dumps, study guide and training courses help you study and pass hassle-free!

From Beginner to LSSWB Certified: Lean Six Sigma Complete Guide

Lean Six Sigma is a structured methodology focused on improving business processes, reducing errors, and increasing efficiency using a data-driven approach. The term sigma refers to variation in statistical terms, and Lean Six Sigma emphasizes minimizing deviation from desired outcomes. The methodology combines principles of Lean management, which focuses on eliminating waste and maximizing value, with Six Sigma techniques that use statistical analysis to enhance process quality. Organizations adopting Lean Six Sigma aim to streamline workflows, reduce costs, and consistently deliver high-quality results while prioritizing customer needs.

The approach encourages a systematic examination of processes to identify bottlenecks and inefficiencies. It promotes collaboration among team members to address challenges collectively and ensures that improvements are sustainable. Lean Six Sigma uses measurable metrics to track progress and validate the effectiveness of process changes. Understanding these foundational principles is essential for anyone preparing for the LSSWB exam, as it forms the basis for more advanced Lean Six Sigma concepts.

Understanding Lean Six Sigma White Belt Certification

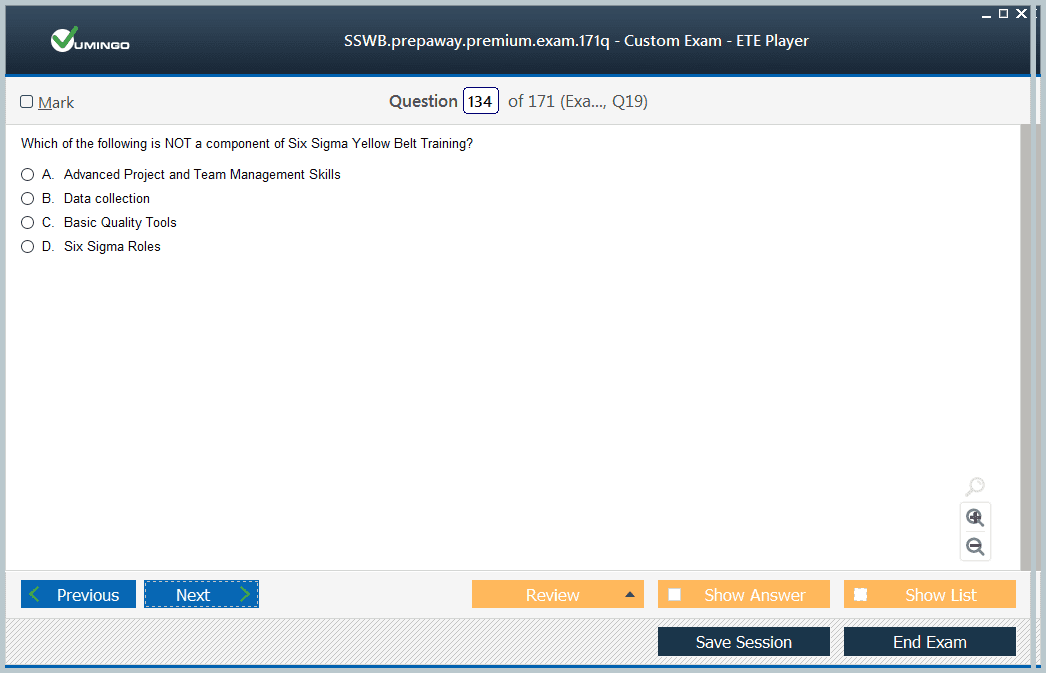

The Lean Six Sigma White Belt certification represents the entry-level credential in the Lean Six Sigma hierarchy. It is designed for individuals who want a basic understanding of Lean Six Sigma principles without taking on leadership responsibilities in projects. White Belt holders gain a foundational knowledge of process improvement, workflow analysis, and the role each team member plays in contributing to project success. The training introduces concepts such as identifying waste, reducing defects, and using data to support decision-making.

LSSWB certification ensures that candidates understand how process improvements impact organizational outcomes. It emphasizes the importance of clear communication, teamwork, and adherence to standardized procedures. The certification prepares participants to support Lean Six Sigma initiatives by recognizing opportunities for improvement, assisting in data collection, and contributing to problem-solving discussions. Candidates also learn to interpret simple process metrics and understand basic statistical tools used in Lean Six Sigma projects.

Key Concepts Tested in the LSSWB Exam

The LSSWB exam evaluates candidates’ understanding of Lean Six Sigma principles at a foundational level. It typically covers topics such as the core concepts of Lean, including waste identification and elimination, process flow optimization, and value stream mapping. Candidates are also tested on Six Sigma fundamentals, including basic statistical concepts, variation, process capability, and problem-solving techniques. Understanding these topics is critical for passing the exam and applying Lean Six Sigma in real-world scenarios.

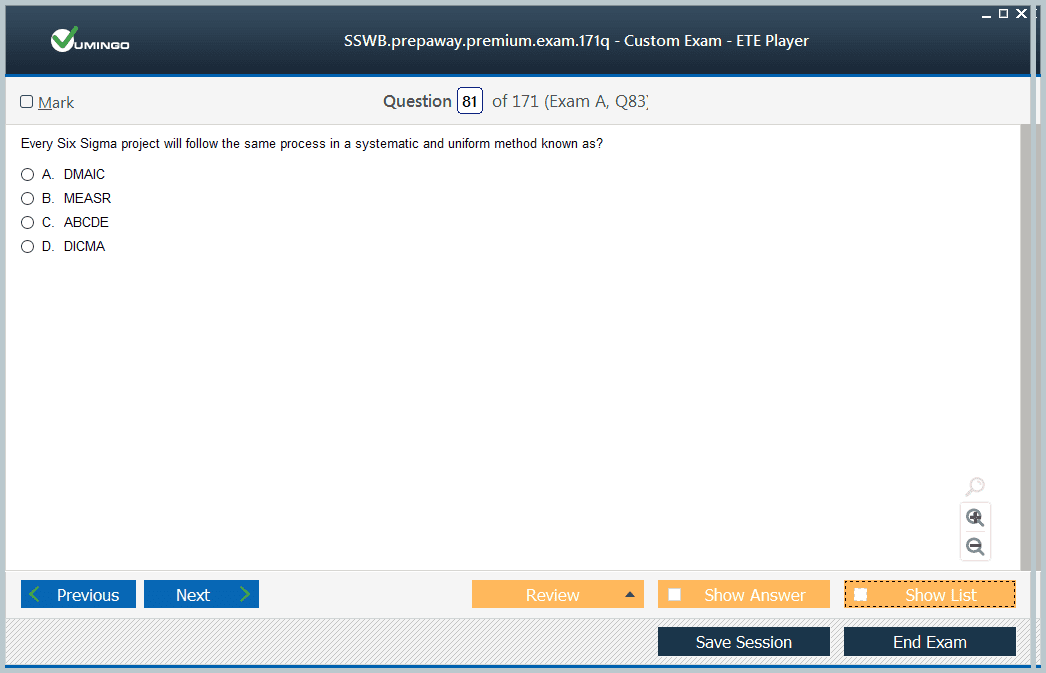

Additionally, the exam assesses awareness of the structured problem-solving approach central to Lean Six Sigma. This includes the Define, Measure, Analyze, Improve, and Control (DMAIC) framework, which guides teams through systematic process improvements. Candidates are expected to recognize how each phase contributes to identifying problems, analyzing root causes, implementing solutions, and maintaining gains. Familiarity with these steps and their practical application is an essential component of LSSWB preparation.

Exam Format and Preparation

Candidates preparing for the LSSWB exam should familiarize themselves with the exam format and question types. The assessment often consists of multiple-choice and scenario-based questions that test conceptual understanding rather than advanced statistical calculations. Candidates need to demonstrate comprehension of Lean Six Sigma principles, the ability to interpret simple data sets, and the skill to recognize opportunities for process improvement.

Effective preparation for the LSSWB exam involves reviewing key Lean Six Sigma concepts, practicing scenario-based questions, and understanding how theoretical principles apply to practical situations. Time management during the exam is important, as candidates must read and analyze scenarios carefully to select the most appropriate response. Building confidence in identifying inefficiencies and applying process improvement concepts helps ensure readiness for the assessment.

Role of White Belt Certification in Career Development

Obtaining LSSWB certification can provide a strong foundation for professional growth. White Belt holders gain an understanding of Lean Six Sigma that enables them to support process improvement projects within their organization. They can assist in data collection, participate in team discussions, and contribute to problem-solving initiatives. This knowledge enhances their ability to work collaboratively with Green Belts and Black Belts, who lead more complex projects.

Certification also signals to employers that an individual has a commitment to understanding structured process improvement methodologies. It demonstrates awareness of organizational efficiency principles and the ability to participate meaningfully in Lean Six Sigma initiatives. While White Belt certification is not intended for project leadership, it equips professionals with the insights and skills necessary to grow into higher levels of Lean Six Sigma expertise over time.

Benefits of Preparing for the LSSWB Exam

Preparing for the LSSWB exam provides several benefits beyond obtaining the certification. Candidates develop analytical thinking, problem-solving skills, and an understanding of how to evaluate process efficiency. The preparation process reinforces knowledge of Lean principles, such as eliminating non-value-added activities, optimizing workflows, and improving operational effectiveness.

Candidates also learn to approach problems methodically, using data to make informed decisions and applying structured frameworks to identify root causes. These skills are directly applicable in professional settings, allowing individuals to contribute to quality improvement initiatives, enhance operational efficiency, and support organizational goals. The preparation for the LSSWB exam builds a mindset focused on continuous improvement and measurable results.

Core Tools and Techniques for LSSWB Candidates

White Belt candidates are introduced to foundational Lean Six Sigma tools and techniques that aid in process improvement. Key tools include process mapping, which visually represents workflow steps and highlights inefficiencies. Understanding process flow diagrams helps candidates identify bottlenecks, redundancies, and areas where errors commonly occur.

Another critical technique is the identification of waste using the Lean framework. Waste may include overproduction, waiting times, excess inventory, unnecessary movement, or defects in outputs. Candidates also learn the importance of data-driven decision-making, emphasizing the collection and interpretation of basic metrics to guide process improvement efforts. Root cause analysis and problem-solving approaches are simplified for White Belt candidates to ensure they can support teams effectively.

Application of Lean Six Sigma in the Workplace

White Belt certification equips candidates with the knowledge to recognize improvement opportunities in everyday workplace processes. By understanding basic Lean Six Sigma principles, they can participate in project teams to enhance efficiency, reduce errors, and contribute to organizational goals. LSSWB holders are able to observe processes critically, offer suggestions for improvement, and assist in implementing changes under the guidance of more advanced practitioners.

The practical application of these principles involves evaluating workflows, measuring performance, and identifying areas that add the most value to customers. White Belt holders also learn to communicate findings effectively, support team decision-making, and contribute to the documentation of improvement initiatives. This foundational understanding helps build confidence in participating in more complex projects in the future.

Strategic Value of LSSWB Certification

Obtaining the LSSWB credential provides strategic value to both individuals and organizations. For individuals, it establishes a base understanding of Lean Six Sigma methodology and prepares them for career advancement into higher certification levels. For organizations, having White Belt certified personnel ensures that teams have a shared understanding of process improvement principles, creating a culture focused on efficiency and continuous improvement.

The certification promotes consistent application of Lean Six Sigma practices across teams and departments, helping organizations maintain quality standards and reduce operational inefficiencies. White Belt holders contribute to creating a more structured and organized approach to problem-solving, supporting the achievement of measurable business outcomes.

Preparing Effectively for LSSWB

Effective preparation for the LSSWB exam involves structured study, familiarization with Lean Six Sigma terminology, and understanding the practical applications of core principles. Candidates should focus on learning the DMAIC framework, basic Lean concepts, process mapping techniques, and the identification of waste. Reviewing examples of common workplace scenarios where Lean Six Sigma principles apply is beneficial in connecting theory to practice.

Practicing scenario-based questions and understanding how foundational concepts are applied to solve problems is key to exam success. Time management and careful reading of questions are critical, as candidates need to interpret situations accurately to select the correct responses. Building a comprehensive understanding of how Lean Six Sigma concepts function in real-world applications ensures readiness for the assessment.

Continuous Learning Beyond White Belt

While the White Belt provides foundational knowledge, it also serves as a stepping stone for further Lean Six Sigma learning. Candidates can build on this foundation to pursue higher levels of certification, where advanced statistical analysis, project leadership, and process optimization strategies are emphasized. Continuous learning helps professionals stay adaptable, understand emerging best practices, and contribute to increasingly complex process improvement initiatives.

White Belt certification encourages a mindset of ongoing improvement and analytical thinking. Candidates develop a habit of evaluating processes, identifying inefficiencies, and seeking opportunities to enhance value. This continuous approach ensures that Lean Six Sigma principles are not just theoretical knowledge but an integral part of workplace practices.

The Importance of Exam Familiarity

Understanding the structure of the LSSWB exam is crucial for effective preparation. Candidates should be aware of the types of questions they may encounter, which generally focus on conceptual understanding, practical application of basic tools, and recognition of process improvement opportunities. Familiarity with the format reduces anxiety, improves time management, and increases the likelihood of passing the exam on the first attempt.

Candidates should practice applying Lean Six Sigma principles to hypothetical workplace scenarios. This helps reinforce theoretical knowledge and provides insights into how concepts translate into actionable improvements. By building confidence in these areas, candidates can approach the exam with a clear understanding of expectations and the ability to apply their knowledge effectively.

Lean Six Sigma White Belt certification provides a solid introduction to process improvement methodologies, equipping candidates with essential knowledge to participate in organizational improvement initiatives. It emphasizes data-driven decision-making, teamwork, and a structured approach to problem-solving. LSSWB certification prepares individuals to support projects, identify inefficiencies, and contribute meaningfully to workflow optimization.

Through preparation and understanding of core principles, candidates gain practical skills applicable to a wide range of professional environments. The certification lays the groundwork for higher levels of Lean Six Sigma expertise, fostering a mindset focused on efficiency, quality, and continuous improvement. Candidates who achieve White Belt certification are well-positioned to advance in their careers while helping organizations implement effective and sustainable process improvements.

Core Principles Evaluated in the LSSWB Exam

Candidates taking the LSSWB exam must grasp several essential Lean Six Sigma principles. The first is customer focus, which emphasizes delivering products or services that meet or exceed expectations. This principle requires understanding value from the customer’s perspective and recognizing activities that do not contribute to value creation.

Process improvement is another key concept assessed in the exam. Candidates should be able to identify inefficiencies, analyze workflows, and suggest improvements that streamline operations. The exam also covers the importance of teamwork and collaboration, highlighting how effective communication and shared responsibility contribute to project success. Problem-solving methods, such as root cause analysis, and data-driven decision-making form the foundation for effective process improvement. Candidates are expected to recognize the impact of errors and understand how controlled changes can lead to consistent performance outcomes.

Exam Structure and Question Types

The Lean Six Sigma White Belt exam typically includes multiple-choice questions and scenario-based questions. Multiple-choice questions assess theoretical knowledge of Lean Six Sigma concepts, including the identification of waste, understanding process flows, and basic statistical reasoning. Scenario-based questions evaluate practical understanding, requiring candidates to apply principles to real-world situations.

Time management is a critical component of the exam. Candidates must be able to read and interpret scenarios accurately, understand the problem, and select the most effective solution. Preparation involves familiarizing oneself with common scenarios, reviewing process improvement tools, and practicing application of core principles. Understanding the exam format and question style enhances confidence and increases the likelihood of success.

Fundamental Tools Covered in the Exam

The LSSWB exam includes questions on foundational Lean Six Sigma tools and techniques. Process mapping is one of the most important tools, helping candidates visualize workflows, identify bottlenecks, and detect redundancies. Basic process flow diagrams are often referenced in the exam, and candidates should be able to interpret them to determine where improvements can be made.

Waste identification is another key topic. Candidates must understand the types of waste commonly found in processes, including overproduction, waiting time, unnecessary movement, defects, and excess inventory. The exam also evaluates understanding of simple metrics and measurements that help assess process performance. Basic problem-solving tools, such as cause-and-effect analysis and brainstorming, are part of the foundational skill set assessed at the White Belt level.

Understanding the DMAIC Framework

A significant portion of the LSSWB exam focuses on the DMAIC framework, which stands for Define, Measure, Analyze, Improve, and Control. This structured approach guides project teams through process improvement initiatives. Define involves understanding the problem, setting objectives, and identifying stakeholders. Measure requires collecting data to establish a baseline and evaluate current performance. Analyze focuses on identifying root causes of inefficiencies or errors. Improve entails implementing solutions to address problems, and Control ensures that improvements are maintained over time.

Candidates are expected to understand the purpose of each DMAIC phase and how it applies to practical scenarios. Familiarity with this framework allows candidates to approach process improvement systematically and respond effectively to scenario-based questions on the exam.

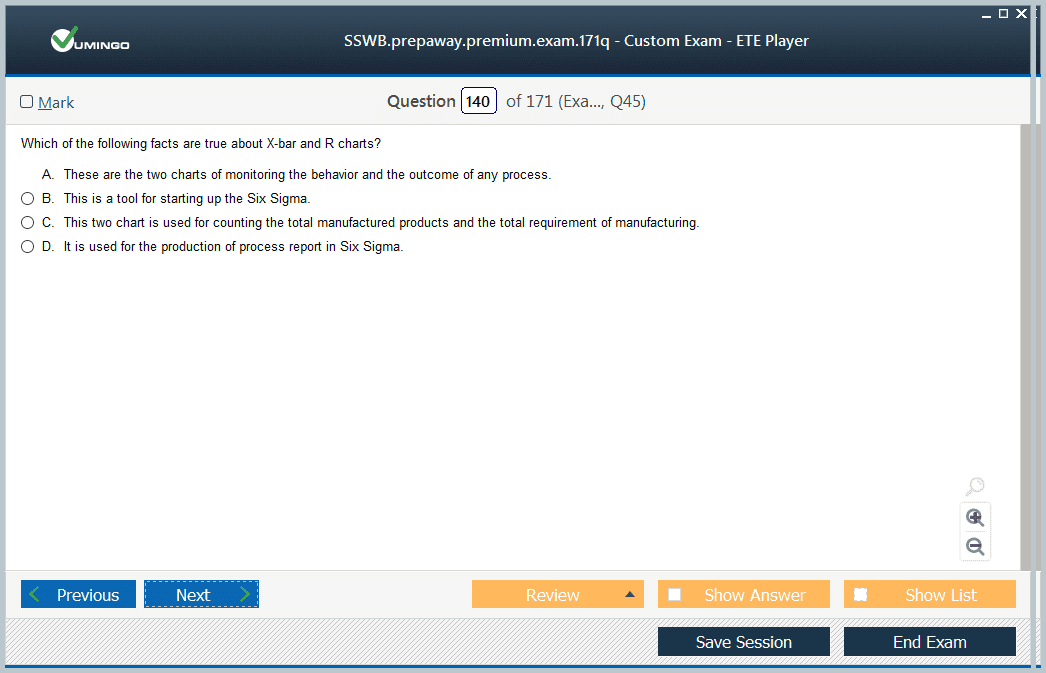

Data Interpretation Skills

While the White Belt exam does not delve deeply into advanced statistical analysis, candidates must demonstrate the ability to interpret basic data. This includes reading simple charts, graphs, and tables to identify trends or performance gaps. Understanding variation in processes, recognizing patterns, and making informed decisions based on data are key skills tested in the exam. Candidates should practice reviewing small datasets and drawing conclusions about process efficiency, error rates, or potential improvements.

The ability to apply data to support recommendations is central to the Lean Six Sigma approach. Even at the White Belt level, candidates need to appreciate how data informs decision-making and guides problem-solving efforts within an organization.

Practical Applications in the Workplace

White Belt certification equips candidates to contribute effectively to workplace process improvement initiatives. Individuals with this credential can assist project teams by collecting data, observing workflows, identifying areas of waste, and suggesting minor improvements. The LSSWB exam tests understanding of these practical applications, emphasizing how foundational knowledge translates into actionable contributions.

Candidates should be familiar with real-life scenarios in which Lean Six Sigma principles can be applied. Examples include reducing cycle times in operational processes, eliminating errors in service delivery, improving coordination between departments, or streamlining simple administrative workflows. Understanding these applications helps candidates see the relevance of theoretical concepts and strengthens their ability to answer scenario-based questions.

Importance of Exam Preparation

Proper preparation for the LSSWB exam is essential to ensure success. Candidates should review foundational Lean Six Sigma concepts, become familiar with process improvement tools, and practice interpreting simple data. Reviewing the DMAIC framework and understanding the purpose of each phase is critical for scenario-based questions.

Effective study methods include using practice exercises, analyzing case studies, and applying concepts to hypothetical workplace situations. Candidates should focus on understanding why processes are improved, how improvements are measured, and what tools are most effective for supporting project teams. Familiarity with these areas ensures candidates can answer questions confidently and accurately.

Benefits of Achieving LSSWB Certification

Obtaining Lean Six Sigma White Belt certification offers several professional benefits. It provides a foundational understanding of process improvement methodologies, preparing individuals to contribute effectively to team initiatives. Candidates gain skills in identifying inefficiencies, understanding workflows, and supporting problem-solving activities.

The certification also enhances credibility within an organization. White Belt holders demonstrate a commitment to continuous improvement and a willingness to learn structured methods for enhancing efficiency. These skills are valuable in a wide range of roles, from administrative support to operational analysis, and provide a basis for advancement into higher levels of Lean Six Sigma certification.

Strategies for Exam Success

To perform well on the LSSWB exam, candidates should adopt targeted strategies. Reviewing all core concepts, understanding process improvement terminology, and practicing scenario-based questions are essential. Time management skills help ensure all questions are addressed thoroughly, and candidates should practice reading scenarios carefully before selecting an answer.

Using practical examples to connect theory to real-world applications reinforces understanding. Candidates should focus on the logic behind Lean Six Sigma methods, recognizing how small improvements can lead to measurable results. By developing both conceptual understanding and practical insight, candidates can approach the exam with confidence and competence.

Continuous Learning and Application

White Belt certification is only the first step in a continuous learning journey. Candidates are encouraged to apply Lean Six Sigma principles in their daily work, supporting projects and participating in improvement initiatives. Practical experience reinforces knowledge gained during preparation and enhances understanding of how Lean Six Sigma impacts organizational performance.

As candidates gain experience, they may pursue advanced certifications to take on more responsibility and lead projects. Even at the White Belt level, continuous engagement with Lean Six Sigma practices helps build analytical thinking, process evaluation skills, and a mindset focused on efficiency and quality.

Exam Mindset and Focus

Approaching the LSSWB exam with the right mindset is critical for success. Candidates should focus on understanding concepts rather than memorizing definitions. Emphasis should be on practical application, recognizing inefficiencies, and applying structured problem-solving methods. Confidence in interpreting process information and making data-informed recommendations improves both exam performance and workplace contribution.

Developing familiarity with common exam scenarios helps candidates anticipate challenges and apply logical reasoning. Being able to connect theoretical concepts to practical situations demonstrates mastery of foundational Lean Six Sigma principles, which is the primary goal of the White Belt certification.

Supporting Organizational Goals

White Belt certified professionals play a supportive but important role in achieving organizational objectives. Their knowledge helps teams identify areas for improvement, implement changes, and monitor the impact of initiatives. Understanding Lean Six Sigma principles allows individuals to contribute to reducing errors, increasing efficiency, and enhancing overall quality.

The LSSWB exam tests knowledge that directly supports these contributions. By demonstrating an understanding of foundational tools, process analysis, and basic problem-solving, candidates show readiness to assist in structured improvement projects. White Belt certification ensures teams have a consistent understanding of methodologies and enables individuals to participate meaningfully in organizational success initiatives.

The Lean Six Sigma White Belt exam provides an opportunity to validate foundational knowledge in process improvement, workflow analysis, and data-driven decision-making. Candidates develop skills to identify inefficiencies, apply basic problem-solving techniques, and support project teams effectively. Understanding Lean and Six Sigma principles, familiarizing oneself with core tools and techniques, and practicing application in real-world scenarios are key to exam success.

Achieving LSSWB certification builds confidence, enhances workplace contribution, and lays the groundwork for further Lean Six Sigma learning. It prepares individuals to participate in structured improvement initiatives, supports organizational goals, and develops a mindset focused on efficiency, quality, and continuous improvement. This certification is a critical first step for professionals seeking to grow in process improvement roles and contribute meaningfully to their teams.

Introduction to Advanced Concepts for LSSWB Exam

The Lean Six Sigma White Belt exam is designed to provide foundational knowledge of process improvement and workflow optimization. Beyond basic concepts, candidates must understand the practical implications of Lean Six Sigma principles in real organizational environments. The exam evaluates the ability to apply knowledge in identifying inefficiencies, supporting team projects, and contributing to measurable improvements. Preparation involves learning both theoretical principles and practical applications, ensuring candidates can participate effectively in process improvement initiatives.

Understanding the broader context of Lean Six Sigma allows candidates to see how White Belt certification fits within a structured improvement framework. It prepares participants to observe, support, and contribute to projects while laying the groundwork for future certification levels. Candidates must also be aware of the importance of process standardization, data-driven decision-making, and collaborative problem-solving as these elements are critical components of the exam.

Core Knowledge Areas for LSSWB Candidates

Candidates taking the LSSWB exam must grasp the fundamental principles of Lean and Six Sigma. Lean focuses on reducing waste, improving flow, and increasing value-added activities. Six Sigma emphasizes consistency, error reduction, and data-driven process analysis. Candidates are expected to identify the relationship between these principles and understand how they work together to improve organizational outcomes.

Key areas include customer focus, where candidates learn to prioritize stakeholder requirements and assess value from the customer perspective. Process efficiency is another core topic, involving the identification of bottlenecks, redundant activities, and sources of variation. Team collaboration is emphasized, highlighting the importance of effective communication, shared responsibility, and coordinated problem-solving. Candidates are also introduced to basic project management concepts, supporting the ability to contribute to process improvement initiatives in structured ways.

Lean Principles in Practice

Lean principles are foundational for White Belt certification. Candidates are assessed on their ability to recognize waste in processes, such as overproduction, unnecessary waiting, excess movement, defects, and over-processing. Understanding these types of waste is critical for contributing to workflow improvement initiatives. Candidates are also introduced to value stream mapping, which visually represents processes, highlights areas for improvement, and helps teams understand the flow of value through the organization.

Process mapping is a central Lean tool included in the exam. Candidates must interpret flowcharts and diagrams to identify bottlenecks, inefficiencies, and opportunities for streamlining. They are also expected to understand the importance of standardizing procedures and ensuring consistent application of improvements to maintain quality and reduce variation.

Six Sigma Foundations for White Belt

Six Sigma principles focus on reducing variability and improving quality in processes. The White Belt exam introduces candidates to the concept of process variation, defect reduction, and the importance of data collection in making informed decisions. Candidates learn how to measure performance, identify trends, and apply simple problem-solving methods to support process improvement initiatives.

The exam emphasizes the practical application of these principles in everyday workplace scenarios. Candidates must understand the relationship between process measurement and improvement, and recognize how incremental changes can lead to significant gains in efficiency and quality. White Belt holders are expected to assist in implementing basic improvement initiatives while understanding the impact of these efforts on overall performance.

The DMAIC Framework and Its Application

DMAIC, which stands for Define, Measure, Analyze, Improve, and Control, is a structured problem-solving methodology that forms the core of Lean Six Sigma practice. Candidates must understand the purpose and application of each phase. Define involves identifying the problem, establishing goals, and determining stakeholders. Measure focuses on collecting baseline data to assess current performance. Analyze is used to identify root causes of inefficiencies or errors. Improve involves implementing solutions to address problems, and Control ensures that improvements are sustained over time.

Understanding DMAIC is critical for success on the LSSWB exam. Candidates must recognize how each phase contributes to effective process improvement and how to apply the framework in practical scenarios. Scenario-based questions often test the ability to select appropriate actions for each phase, demonstrating comprehension of the methodology and readiness to support project teams.

Tools and Techniques for White Belt Candidates

The LSSWB exam covers essential Lean Six Sigma tools that support process improvement. Candidates are expected to understand process mapping, which helps visualize workflow, identify redundancies, and highlight areas for improvement. They should also be familiar with simple problem-solving techniques such as brainstorming, cause-and-effect analysis, and checklists.

Waste identification is a critical skill assessed in the exam. Candidates must recognize activities that do not add value and understand how to suggest improvements. Basic data interpretation skills, including reading charts, graphs, and tables, are also tested. Candidates should be able to analyze simple datasets, draw conclusions, and propose improvements that align with Lean Six Sigma principles.

Scenario-Based Applications in the Exam

Scenario-based questions assess the practical understanding of Lean Six Sigma principles. Candidates may encounter examples of workplace processes where inefficiencies need to be identified and solutions proposed. These scenarios require candidates to apply their knowledge of Lean and Six Sigma tools, recognize sources of waste, and determine the most appropriate improvement actions.

Effective preparation involves practicing with hypothetical scenarios and understanding how theoretical concepts translate into practical actions. Candidates should focus on recognizing patterns, interpreting data, and suggesting actionable improvements. This approach ensures readiness for scenario-based questions and strengthens the ability to contribute effectively to organizational initiatives.

Data Interpretation and Basic Statistical Skills

While the White Belt exam does not require advanced statistical analysis, candidates must be able to interpret basic data to support process improvements. This includes reading simple charts, identifying trends, and understanding variations in performance. Candidates should practice reviewing data to determine areas for improvement, assess the impact of changes, and support team decisions with evidence.

Data-driven decision-making is a fundamental Lean Six Sigma principle. White Belt candidates must demonstrate the ability to connect observations from data to potential process enhancements, ensuring that recommendations are grounded in measurable evidence.

Exam Preparation Strategies

Successful preparation for the LSSWB exam involves understanding core Lean Six Sigma concepts, practicing scenario-based questions, and reviewing practical applications of tools and frameworks. Candidates should focus on applying theory to real-world situations, interpreting workflows, and identifying areas for improvement.

Structured study approaches include reviewing key terminology, practicing process mapping exercises, and analyzing common workplace scenarios. Time management is essential, as candidates need to read questions carefully and select the most appropriate response. Confidence in applying concepts and analyzing situations is key to performing well on the exam.

Workplace Applications of White Belt Certification

White Belt certification equips professionals to participate effectively in process improvement projects. LSSWB holders can assist teams by collecting data, observing workflows, identifying inefficiencies, and contributing to problem-solving discussions. They learn to recognize non-value-added activities and propose minor improvements under guidance from more experienced team members.

This foundational knowledge enhances analytical thinking, improves understanding of process dynamics, and strengthens communication skills. White Belt certification provides a stepping stone for career advancement, preparing individuals for higher levels of Lean Six Sigma certification and increased responsibilities in process improvement initiatives.

Continuous Learning and Development

White Belt certification encourages ongoing learning and application of Lean Six Sigma principles. Candidates are advised to apply knowledge in workplace settings, participate in improvement projects, and gain hands-on experience. This practical engagement reinforces theoretical understanding and develops skills required for higher certification levels.

Ongoing learning enables professionals to proactively identify inefficiencies, support decision-making, and contribute to process improvements. Continuous application ensures that Lean Six Sigma principles are integrated into daily work, fostering a culture of efficiency, quality, and measurable results.

Strategic Importance of LSSWB Certification

The White Belt certification provides strategic value by validating foundational knowledge of Lean Six Sigma. Candidates demonstrate readiness to support improvement projects, interpret data, and contribute to workflow optimization. Organizations benefit from certified personnel who understand process improvement principles, enabling consistent application and supporting operational excellence.

Certified White Belt holders play a role in enhancing team collaboration, improving process efficiency, and facilitating structured problem-solving. Their contributions help achieve organizational objectives and maintain consistent quality standards, ensuring that Lean Six Sigma principles are embedded throughout the workplace.

Mindset and Approach for Exam Success

Approaching the LSSWB exam with a focused mindset is critical. Candidates should prioritize understanding and applying concepts rather than memorization. Emphasis should be placed on analyzing scenarios, identifying problems, and proposing practical solutions based on Lean Six Sigma principles.

Practicing real-world scenarios and reflecting on improvement opportunities helps candidates develop logical, structured thinking. This mindset supports success in scenario-based questions and ensures comprehension of core principles, which is essential for effective participation in process improvement initiatives.

Long-Term Benefits of White Belt Certification

LSSWB certification offers long-term professional benefits. It provides foundational skills for supporting projects, analyzing processes, and implementing basic improvements. Candidates develop analytical thinking, problem-solving capabilities, and understanding of workflow optimization, all of which contribute to organizational success.

The certification also serves as a basis for further advancement within Lean Six Sigma. Continuous application of knowledge builds expertise, preparing candidates for higher levels of certification where advanced tools, statistical methods, and leadership responsibilities are emphasized. White Belt holders gain credibility, enhance workplace performance, and develop a mindset focused on continuous improvement.

Practical Contributions in Organizations

White Belt certified professionals contribute to measurable improvements in operational efficiency and quality. By supporting teams, identifying inefficiencies, and assisting in problem-solving, they enhance organizational performance. Knowledge of Lean Six Sigma principles allows candidates to participate in structured initiatives, improve workflows, and support data-driven decision-making.

Practical contributions may include analyzing simple processes, suggesting minor improvements, collecting performance data, and ensuring that teams follow structured improvement methods. White Belt certification ensures that individuals have the knowledge and skills to make meaningful contributions even at an entry-level position, providing value to both their team and the organization.

Preparation and Practice Recommendations

Candidates preparing for the LSSWB exam should focus on understanding fundamental principles, practicing scenario-based questions, and reviewing the DMAIC framework. Emphasis should be placed on applying theoretical knowledge to practical scenarios, interpreting simple data, and identifying improvement opportunities.

Engaging in structured exercises such as process mapping, waste identification, and basic data analysis strengthens understanding and confidence. Reviewing case studies and hypothetical workflows helps connect theory to practice, ensuring candidates are equipped to answer both conceptual and applied questions accurately.

The Lean Six Sigma White Belt exam validates foundational knowledge in process improvement, workflow analysis, and data-driven decision-making. Candidates develop the ability to support project teams, identify inefficiencies, apply basic tools, and contribute to organizational improvements. Understanding Lean and Six Sigma principles, practicing scenario-based applications, and applying the DMAIC framework are essential for exam success.

White Belt certification builds professional credibility, enhances workplace contributions, and prepares candidates for advanced Lean Six Sigma learning. It equips individuals with the skills to participate effectively in improvement initiatives, support operational excellence, and foster a culture of continuous improvement. LSSWB certified professionals gain a strong foundation for long-term career growth and meaningful contributions to organizational performance

Advanced Preparation for LSSWB Exam

The Lean Six Sigma White Belt exam requires candidates to have a clear understanding of basic process improvement concepts and practical applications. Beyond theory, it evaluates the ability to observe workflows, identify inefficiencies, and support project teams in making measurable improvements. Advanced preparation focuses on understanding the principles of Lean and Six Sigma, familiarizing with key tools, and practicing scenario-based questions to build problem-solving skills. Candidates must also understand the organizational context in which Lean Six Sigma methods are applied, ensuring that knowledge gained can be effectively translated into workplace contributions.

Preparation should include reviewing key Lean Six Sigma concepts such as customer focus, waste reduction, process optimization, and data-driven decision-making. Candidates should also study the DMAIC framework, understanding the role of each phase and how it guides structured process improvement. Familiarity with common process mapping tools, waste identification techniques, and basic data interpretation methods is essential for both the exam and practical application in professional settings.

Core Lean Concepts for White Belt

Lean principles are fundamental to the White Belt exam and are evaluated in both theoretical and practical questions. Candidates need to understand how to identify and eliminate different types of waste, including overproduction, waiting, unnecessary transportation, overprocessing, excess inventory, and defects. They should also understand the importance of value-added activities and how to optimize workflows to maximize value creation.

Process mapping is a critical Lean tool included in the exam. Candidates should be able to read and interpret process flow diagrams, identify bottlenecks, and suggest improvements to enhance efficiency. Standardization of processes is another key area, where candidates learn how consistent procedures reduce variation, improve quality, and facilitate continuous improvement.

Six Sigma Foundations

Six Sigma principles emphasize reducing variation and improving process quality through structured problem-solving approaches. White Belt candidates are introduced to the concepts of process variation, defect reduction, and the importance of data in decision-making. The exam evaluates understanding of how simple measurement techniques can identify performance gaps and guide improvement efforts.

Candidates should understand the importance of defining problems clearly, establishing measurable objectives, and collecting baseline data. Even at the White Belt level, understanding how small, incremental improvements contribute to overall process performance is critical. The exam also assesses the ability to support project teams in applying these principles to practical workplace situations.

DMAIC Framework for White Belt

The DMAIC framework, standing for Define, Measure, Analyze, Improve, and Control, is central to Lean Six Sigma practice and the White Belt exam. Define involves understanding the problem, setting objectives, and identifying stakeholders. Measure focuses on collecting data to establish baseline performance. Analyze identifies root causes of inefficiencies. Improve involves implementing solutions, and Control ensures that improvements are maintained over time.

Candidates should understand how each DMAIC phase contributes to structured problem-solving and be able to apply this framework to scenario-based questions. Understanding DMAIC helps candidates see the logical flow of improvement projects and demonstrates their ability to support teams in achieving measurable results.

Essential Tools and Techniques

The LSSWB exam evaluates knowledge of basic Lean Six Sigma tools that facilitate process improvement. Candidates should understand process mapping, cause-and-effect analysis, brainstorming, checklists, and simple data interpretation methods. Waste identification is a core skill, requiring candidates to recognize activities that do not add value and propose practical improvements.

Data interpretation is an important component. Candidates must be able to read charts, graphs, and simple tables to assess performance trends, identify inefficiencies, and support recommendations for process improvement. These skills ensure that White Belt certified professionals can contribute meaningfully to project teams and support operational improvements.

Scenario-Based Applications

Scenario-based questions test candidates’ ability to apply Lean Six Sigma principles in real-world situations. Candidates may be asked to analyze workflows, identify inefficiencies, and propose corrective actions. Preparing for these questions requires understanding theoretical concepts and practicing their application to workplace scenarios.

Candidates should focus on logical problem-solving, connecting observations from scenarios to potential process improvements. Practicing with example scenarios helps develop analytical thinking, decision-making skills, and familiarity with the types of challenges that might appear on the exam. This approach ensures readiness for both conceptual and applied questions.

Data Analysis and Interpretation

Although advanced statistical analysis is not required, candidates must understand basic data interpretation. This includes analyzing trends, evaluating variations, and using data to support recommendations. Candidates should practice interpreting simple datasets to identify improvement opportunities and support decision-making in a structured manner.

Understanding how to apply data-driven insights ensures that White Belt certified professionals can make meaningful contributions to team projects, identify process inefficiencies, and propose practical solutions. It also lays the foundation for more advanced data analysis skills required at higher Lean Six Sigma certification levels.

Exam Preparation Strategies

Effective preparation for the LSSWB exam requires a combination of conceptual review and practical exercises. Candidates should study Lean and Six Sigma principles, understand DMAIC, and practice scenario-based questions. Structured study sessions focusing on tools, frameworks, and real-world applications help build confidence and competence.

Candidates should also develop time management strategies to ensure that all questions are carefully read and answered. Reviewing example workflows, practicing data interpretation, and simulating exam conditions can enhance readiness. Understanding the practical relevance of each concept ensures that candidates are prepared to apply knowledge both on the exam and in the workplace.

Workplace Applications of White Belt Certification

White Belt certification equips professionals to support Lean Six Sigma projects effectively. Candidates learn to observe workflows, identify inefficiencies, and assist in problem-solving efforts. They contribute by collecting data, analyzing simple processes, and proposing minor improvements under the guidance of experienced team members.

This practical knowledge enhances analytical skills, improves communication, and strengthens understanding of organizational processes. White Belt certification provides a foundation for career growth, preparing candidates to pursue higher certifications and take on more responsibility in process improvement initiatives.

Continuous Learning and Professional Growth

Achieving White Belt certification marks the beginning of a continuous learning journey in Lean Six Sigma. Candidates are encouraged to apply principles in the workplace, engage in improvement initiatives, and gain hands-on experience. This reinforces theoretical knowledge and develops critical skills needed for advanced certification levels.

Continuous practice and application of Lean Six Sigma concepts enable professionals to proactively identify inefficiencies, contribute to decision-making, and support process improvements. Engaging in ongoing learning ensures that principles are applied consistently, fostering a culture of quality, efficiency, and measurable results.

Strategic Importance of White Belt Certification

White Belt certification provides strategic value by validating foundational knowledge and demonstrating readiness to support process improvement projects. Organizations benefit from certified personnel who understand basic Lean Six Sigma principles, enabling structured improvement initiatives and consistent application of methodologies.

Certified White Belt holders contribute to team collaboration, process optimization, and structured problem-solving. Their involvement helps achieve operational objectives, improve quality, and embed continuous improvement practices within the organization. This strategic contribution enhances both individual and organizational performance.

Mindset for Exam Success

Approaching the LSSWB exam with a focused and practical mindset is crucial. Candidates should prioritize understanding concepts and applying them in scenarios rather than memorizing definitions. Emphasis should be on analyzing situations, identifying problems, and recommending improvements using Lean Six Sigma principles.

Practicing with hypothetical workflows, reflecting on potential improvements, and connecting theoretical knowledge to practical applications develops structured thinking. This mindset is essential for effectively answering scenario-based questions and demonstrating a clear understanding of foundational concepts.

Long-Term Benefits of Certification

White Belt certification provides a strong foundation for professional growth. Candidates gain skills in process observation, problem-solving, and workflow optimization, which are valuable across various organizational roles. Certification enhances credibility, prepares individuals for higher-level certifications, and supports participation in improvement initiatives.

Continuous application of Lean Six Sigma principles allows candidates to develop analytical and decision-making skills, contributing to sustainable improvements. White Belt holders are positioned to support teams effectively, assist in operational efficiency projects, and lay the groundwork for leadership roles in process improvement initiatives.

Practical Contributions in the Workplace

Certified White Belt professionals contribute to operational efficiency by supporting teams in process evaluation, identifying inefficiencies, and assisting in implementing improvements. They learn to analyze workflows, interpret basic data, and support structured problem-solving efforts.

Their contributions ensure that teams can achieve measurable improvements, reduce errors, and enhance the quality of processes. White Belt certification equips individuals with the foundational knowledge and skills to make meaningful contributions even at entry-level positions, ensuring value to both the team and organization.

Effective Study Techniques

To maximize success on the LSSWB exam, candidates should adopt effective study techniques. This includes reviewing Lean Six Sigma principles, practicing process mapping, and analyzing scenario-based questions. Engaging with hypothetical workflows and interpreting simple data reinforces understanding and application of concepts.

Structured study sessions, consistent practice, and self-assessment of knowledge gaps help build confidence. Time management during preparation and exam-taking ensures that candidates can respond to all questions thoughtfully and accurately. Understanding the real-world application of concepts enhances both exam performance and workplace effectiveness.

The Lean Six Sigma White Belt exam validates foundational knowledge in process improvement, workflow optimization, and basic problem-solving techniques. Candidates develop the skills to support project teams, analyze processes, interpret data, and contribute to organizational improvements. Mastery of Lean and Six Sigma principles, familiarity with the DMAIC framework, and practical application of tools are essential for exam success.

White Belt certification enhances professional credibility, provides a foundation for continuous improvement, and prepares candidates for advanced Lean Six Sigma certifications. Certified individuals gain the skills to participate meaningfully in improvement initiatives, support operational excellence, and contribute to a culture of efficiency, quality, and measurable results. LSSWB certified professionals build a strong foundation for long-term career growth and impactful contributions to organizational success

Deep Understanding of LSSWB Exam Objectives

The Lean Six Sigma White Belt exam evaluates a candidate's foundational comprehension of process improvement and workflow efficiency. It is designed to ensure that participants understand how Lean and Six Sigma principles work together to enhance organizational performance. Candidates are assessed on their ability to identify inefficiencies, support improvement projects, and contribute to measurable outcomes. Preparing for the exam requires a combination of theoretical study and practical application, emphasizing the relevance of Lean Six Sigma principles in real-world settings.

Candidates should focus on developing a clear understanding of the interrelationship between Lean and Six Sigma. Lean emphasizes efficiency and waste reduction while Six Sigma focuses on quality, variation control, and data-driven decision-making. The White Belt exam assesses how effectively candidates can integrate these concepts to identify opportunities for improvement and support project teams.

Key Knowledge Areas for LSSWB Candidates

White Belt candidates are expected to have a working knowledge of essential Lean Six Sigma concepts. Customer focus is fundamental, requiring candidates to evaluate processes from the perspective of value delivery. Candidates should understand how to identify non-value-added activities and propose strategies for improvement.

Process efficiency is another crucial area, emphasizing the ability to observe workflows, detect bottlenecks, and identify redundancies. Candidates should also understand the importance of collaboration within project teams, recognizing how structured communication and collective problem-solving contribute to successful process improvements.

Lean Principles and Waste Management

Lean principles are central to the White Belt exam. Candidates must identify various types of waste such as overproduction, waiting, unnecessary transportation, defects, overprocessing, and excess inventory. Understanding these waste types allows participants to support initiatives aimed at streamlining workflows and maximizing value creation.

Process mapping is a critical tool in Lean. Candidates should be able to interpret flowcharts and diagrams to pinpoint inefficiencies and areas for enhancement. Standardizing processes is another key concept, helping organizations maintain consistent quality, reduce errors, and facilitate continuous improvement.

Six Sigma Fundamentals for White Belt

Six Sigma introduces the concept of reducing process variation and improving quality using structured problem-solving methods. White Belt candidates should understand the role of data in identifying performance gaps, measuring process outcomes, and guiding improvement efforts.

Candidates must also be familiar with basic techniques for defining problems, setting objectives, and collecting relevant data. These foundational skills help participants contribute effectively to team projects, support workflow analysis, and understand how incremental improvements can lead to significant performance gains.

Applying the DMAIC Framework

The DMAIC methodology—Define, Measure, Analyze, Improve, and Control—is a structured approach to problem-solving in Lean Six Sigma. Define focuses on understanding the problem, setting objectives, and identifying stakeholders. Measure involves collecting baseline data to assess current performance. Analyze identifies root causes of inefficiencies, while Improve implements solutions, and Control ensures sustainability of improvements.

Candidates must understand the purpose of each phase and how to apply the framework to practical scenarios. Knowledge of DMAIC enables participants to support projects systematically, contributing to measurable improvements and demonstrating a structured approach to process enhancement.

Essential Tools for White Belt Candidates

The LSSWB exam evaluates understanding of foundational tools used in Lean Six Sigma. Candidates should be familiar with process mapping, cause-and-effect diagrams, brainstorming, checklists, and basic data interpretation. Waste identification is a key skill, requiring the ability to recognize non-value-added activities and propose actionable improvements.

Data interpretation skills, including reading charts and tables, are also assessed. Candidates must be able to draw meaningful conclusions from simple datasets, understand trends, and recommend process improvements that align with Lean Six Sigma principles. These tools equip White Belt certified professionals to contribute effectively to improvement initiatives.

Scenario-Based Applications

Scenario-based questions are a critical component of the LSSWB exam. Candidates may be asked to evaluate workflows, identify inefficiencies, and suggest corrective actions. Practicing scenario-based problems helps participants apply theoretical knowledge to real-world situations, enhancing analytical and decision-making skills.

Candidates should focus on logical problem-solving, connecting observations to potential improvements. Reviewing hypothetical workflows and analyzing common inefficiencies helps build familiarity with exam questions and strengthens the ability to respond accurately in practical situations.

Understanding Data and Metrics

Even at the White Belt level, data interpretation is an essential skill. Candidates are expected to analyze trends, measure variations, and support process improvement initiatives using evidence-based insights. Simple statistical concepts such as averages, counts, and basic charts are included to evaluate understanding of data-driven decision-making.

Applying these skills in workplace scenarios allows candidates to make informed recommendations, track performance improvements, and support project teams in implementing sustainable changes. Understanding the relevance of data in Lean Six Sigma ensures that improvements are measurable and effective.

Exam Preparation Techniques

Effective preparation for the LSSWB exam involves reviewing core concepts, practicing scenario-based questions, and familiarizing with key tools. Candidates should focus on understanding principles rather than memorizing definitions, applying knowledge to realistic workplace situations.

Structured practice includes reviewing terminology, creating process maps, identifying waste, and interpreting sample data. Simulating exam conditions can improve time management and confidence. Understanding the practical relevance of Lean Six Sigma principles helps ensure readiness for both conceptual and applied questions.

Workplace Applications of White Belt Certification

White Belt certification enables professionals to support Lean Six Sigma projects by observing workflows, identifying inefficiencies, and assisting with process improvements. Candidates learn to collect data, evaluate processes, and propose minor improvements while collaborating with experienced team members.

This foundational knowledge enhances analytical thinking, improves communication skills, and strengthens understanding of organizational processes. White Belt certification provides the groundwork for future career growth, enabling candidates to pursue advanced Lean Six Sigma certifications and assume greater responsibilities in process improvement initiatives.

Continuous Learning and Professional Development

Achieving White Belt certification marks the beginning of ongoing development in Lean Six Sigma. Candidates are encouraged to apply principles in real projects, participate in improvement initiatives, and gain hands-on experience. Continuous practice reinforces understanding and develops skills necessary for higher-level certifications.

Engaging in real-world projects allows professionals to proactively identify inefficiencies, support decision-making, and implement improvements. Continuous learning ensures that Lean Six Sigma principles become embedded in everyday practice, fostering a culture of quality, efficiency, and measurable results.

Strategic Value of White Belt Certification

White Belt certification provides strategic value by demonstrating foundational knowledge and readiness to support process improvement projects. Organizations benefit from personnel who understand Lean Six Sigma principles, enabling structured improvement initiatives and consistent methodology application.

Certified White Belt holders enhance team collaboration, contribute to process optimization, and support structured problem-solving. Their involvement helps organizations achieve operational goals, improve quality, and embed continuous improvement practices across teams. This strategic contribution enhances both individual performance and organizational effectiveness.

Developing the Right Mindset for Exam Success

Success on the LSSWB exam requires a mindset focused on comprehension and application. Candidates should prioritize understanding core principles and learning how to apply them in practical scenarios. Emphasis should be placed on analyzing situations, identifying problems, and proposing solutions aligned with Lean Six Sigma methodology.

Practicing with hypothetical workflows, reflecting on improvement opportunities, and connecting theoretical knowledge to real-world applications fosters structured thinking. This approach enhances performance on scenario-based questions and ensures candidates demonstrate mastery of foundational concepts.

Long-Term Professional Benefits

White Belt certification provides long-term benefits by establishing a foundation in process improvement, workflow analysis, and data-driven decision-making. Candidates develop analytical and problem-solving skills, which are valuable in multiple organizational contexts. Certification enhances professional credibility, prepares candidates for advanced certifications, and enables effective participation in improvement initiatives.

Continuous application of Lean Six Sigma principles allows individuals to develop deeper expertise, contribute to sustainable improvements, and build a career in process optimization. White Belt holders are equipped to support teams, drive operational efficiency, and prepare for leadership roles in process improvement initiatives.

Practical Workplace Contributions

Certified White Belt professionals play a crucial role in supporting operational improvements. They assist teams in evaluating processes, identifying inefficiencies, and implementing basic solutions. Candidates gain experience in analyzing workflows, interpreting data, and contributing to structured problem-solving.

These contributions enable measurable improvements in efficiency and quality, ensuring that teams achieve operational goals. White Belt certification equips individuals with the knowledge and skills to deliver value even at entry-level positions, supporting organizational performance and fostering a culture of continuous improvement.

Effective Study and Practice Methods

To succeed on the LSSWB exam, candidates should adopt structured study techniques. This includes reviewing Lean and Six Sigma concepts, practicing process mapping, and analyzing scenario-based questions. Engaging with hypothetical workflows and interpreting sample datasets reinforces comprehension and practical application.

Consistent practice, self-assessment, and time management are critical for exam readiness. Candidates should focus on connecting theory to practical applications, ensuring that they are able to respond accurately and confidently to both conceptual and applied questions. Understanding the relevance of each concept enhances exam performance and workplace effectiveness.

Conclusion

The Lean Six Sigma White Belt exam validates foundational knowledge in process improvement, workflow optimization, and basic problem-solving techniques. Candidates develop skills to support project teams, analyze processes, interpret data, and contribute to organizational improvement initiatives. Understanding Lean and Six Sigma principles, mastering the DMAIC framework, and applying practical tools are essential for success.

White Belt certification enhances professional credibility, provides a foundation for continuous improvement, and prepares candidates for advanced Lean Six Sigma learning. Certified individuals gain the skills to participate meaningfully in improvement projects, support operational excellence, and foster a culture focused on efficiency, quality, and measurable results. LSSWB certified professionals establish a strong foundation for long-term career development and impactful contributions to organizational performance

Six Sigma LSSWB practice test questions and answers, training course, study guide are uploaded in ETE Files format by real users. Study and Pass LSSWB Lean Six Sigma White Belt certification exam dumps & practice test questions and answers are to help students.

Purchase LSSWB Exam Training Products Individually

Why customers love us?

What do our customers say?

The resources provided for the Six Sigma certification exam were exceptional. The exam dumps and video courses offered clear and concise explanations of each topic. I felt thoroughly prepared for the LSSWB test and passed with ease.

Studying for the Six Sigma certification exam was a breeze with the comprehensive materials from this site. The detailed study guides and accurate exam dumps helped me understand every concept. I aced the LSSWB exam on my first try!

I was impressed with the quality of the LSSWB preparation materials for the Six Sigma certification exam. The video courses were engaging, and the study guides covered all the essential topics. These resources made a significant difference in my study routine and overall performance. I went into the exam feeling confident and well-prepared.

The LSSWB materials for the Six Sigma certification exam were invaluable. They provided detailed, concise explanations for each topic, helping me grasp the entire syllabus. After studying with these resources, I was able to tackle the final test questions confidently and successfully.

Thanks to the comprehensive study guides and video courses, I aced the LSSWB exam. The exam dumps were spot on and helped me understand the types of questions to expect. The certification exam was much less intimidating thanks to their excellent prep materials. So, I highly recommend their services for anyone preparing for this certification exam.

Achieving my Six Sigma certification was a seamless experience. The detailed study guide and practice questions ensured I was fully prepared for LSSWB. The customer support was responsive and helpful throughout my journey. Highly recommend their services for anyone preparing for their certification test.

I couldn't be happier with my certification results! The study materials were comprehensive and easy to understand, making my preparation for the LSSWB stress-free. Using these resources, I was able to pass my exam on the first attempt. They are a must-have for anyone serious about advancing their career.

The practice exams were incredibly helpful in familiarizing me with the actual test format. I felt confident and well-prepared going into my LSSWB certification exam. The support and guidance provided were top-notch. I couldn't have obtained my Six Sigma certification without these amazing tools!

The materials provided for the LSSWB were comprehensive and very well-structured. The practice tests were particularly useful in building my confidence and understanding the exam format. After using these materials, I felt well-prepared and was able to solve all the questions on the final test with ease. Passing the certification exam was a huge relief! I feel much more competent in my role. Thank you!

The certification prep was excellent. The content was up-to-date and aligned perfectly with the exam requirements. I appreciated the clear explanations and real-world examples that made complex topics easier to grasp. I passed LSSWB successfully. It was a game-changer for my career in IT!