Pass Six Sigma Lean Six Sigma Yellow Belt Certification Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

LSSYB Premium Bundle

- Premium File 150 Questions & Answers. Last update: Feb 15, 2026

- Training Course 84 Video Lectures

- Study Guide 382 Pages

LSSYB Premium Bundle

- Premium File 150 Questions & Answers

Last update: Feb 15, 2026 - Training Course 84 Video Lectures

- Study Guide 382 Pages

Purchase Individually

Premium File

Training Course

Study Guide

LSSYB Exam - Lean Six Sigma Yellow Belt

| Download Free LSSYB Exam Questions |

|---|

Six Sigma Lean Six Sigma Yellow Belt Certification Practice Test Questions and Answers, Six Sigma Lean Six Sigma Yellow Belt Certification Exam Dumps

All Six Sigma Lean Six Sigma Yellow Belt certification exam dumps, study guide, training courses are prepared by industry experts. Six Sigma Lean Six Sigma Yellow Belt certification practice test questions and answers, exam dumps, study guide and training courses help candidates to study and pass hassle-free!

The Foundations of Lean Six Sigma Yellow Belt

In today’s competitive business world, organizations are constantly searching for ways to deliver better products and services more efficiently. The philosophy of continuous improvement is the engine that drives this pursuit of excellence. It is a dedicated, ongoing effort to enhance processes, products, and services. This approach is not about making one-time, revolutionary changes but rather about implementing small, incremental improvements consistently over time. It fosters a culture where every employee, from the front line to the executive suite, is empowered to identify and eliminate inefficiencies in their daily work.

The core idea is that perfection is an unattainable goal, but the relentless pursuit of it leads to significant progress. This mindset shifts the focus from blaming individuals for errors to examining the processes that led to those errors. By improving the process, the organization can prevent similar mistakes from happening in the future. Methodologies like Lean and Six Sigma provide the structured frameworks and tools necessary to turn this philosophy into a practical, results-driven reality. They offer a systematic way to analyse problems, make data-driven decisions, and sustain improvements for long-term success.

The Core Principles of Lean Methodology

The Lean methodology has its roots in the Toyota Production System, a manufacturing philosophy developed in Japan after World War II. Its primary goal is to maximize customer value while minimizing waste. Lean is not just a set of tools; it is a way of thinking that centres on creating more value for customers with fewer resources. This is achieved by systematically identifying and eliminating activities that do not add value, often referred to as "waste." By focusing on the customer's perspective, Lean ensures that all efforts are directed towards what truly matters to the person paying for the product or service.

Lean thinking is guided by five core principles. The first is to specify value from the customer's standpoint. The second is to identify the value stream, which includes all the steps required to bring a product or service to the customer. The third principle is to make the value-creating steps flow without interruption. The fourth is to establish a pull system, where nothing is produced until the customer requests it. Finally, the fifth principle is the pursuit of perfection, continuously striving to improve the process. These principles provide a roadmap for organizations to transform their operations and deliver superior value.

Identifying the Eight Wastes of Lean

A central practice in the Lean methodology is the identification and elimination of waste. Originally, there were seven wastes identified, but an eighth has been commonly added over time. These are often remembered by the acronym TIMWOODS. The first waste is Transportation, which involves the unnecessary movement of products or materials. Next is Inventory, which refers to having more materials or products on hand than are needed for the immediate work. Motion is the unnecessary movement of people, such as walking to get a tool that could be closer.

The fourth waste is Waiting, which includes any idle time when people or machines are waiting for the next step in a process to occur. Overproduction is producing more of a product or service than is currently needed or demanded by the customer. Over-processing involves doing more work or adding more features than are necessary to produce the desired outcome. Defects are errors or mistakes that require correction, which consumes time and resources. The eighth waste, Skills, refers to the underutilization of employees' talents, ideas, and abilities, failing to engage them in the improvement process.

The Fundamentals of Six Sigma Methodology

Six Sigma is a data-driven methodology that originated at Motorola in the 1980s. Its primary objective is to improve quality by reducing process variation and eliminating defects. The name "Six Sigma" refers to a statistical goal of having no more than 3.4 defects per million opportunities. This represents a process that is operating at a near-perfect level of quality. Unlike Lean, which focuses on flow and waste elimination, Six Sigma's core focus is on achieving consistent, predictable, and stable process results. It uses statistical analysis to understand process performance and identify the root causes of problems.

The methodology is built on the principle that every process has measurable characteristics, and by controlling these characteristics, you can control the quality of the output. Six Sigma provides a structured framework for tackling complex problems that do not have obvious solutions. It emphasizes making decisions based on verifiable data and statistical methods rather than on assumptions or gut feelings. This rigorous, fact-based approach ensures that improvements are effective and sustainable. It is widely used in industries from manufacturing to healthcare to finance to solve problems related to quality and customer satisfaction.

The Belt Hierarchy in Six Sigma

Six Sigma uses a belt-based hierarchy, inspired by martial arts, to designate different levels of training, expertise, and responsibility within the organization. At the introductory level is the White Belt, which represents a basic awareness of Six Sigma concepts. White Belts understand the terminology but do not typically participate directly in project teams. The next level is the Yellow Belt. Yellow Belts have a foundational understanding of the methodology and often serve as valuable team members on improvement projects, supporting higher-level belts by collecting data and helping to implement changes in their work areas.

Above the Yellow Belt is the Green Belt. Green Belts have a more in-depth understanding of the Six Sigma framework and tools. They are capable of leading smaller-scale improvement projects under the guidance of a Black Belt. Black Belts are full-time project leaders who are experts in the Six Sigma methodology. They lead complex, cross-functional projects and mentor Green Belts. At the top of the hierarchy is the Master Black Belt. Master Black Belts are responsible for the strategic deployment of Six Sigma within the organization, mentoring Black Belts, and ensuring the overall success of the continuous improvement program.

Combining Lean and Six Sigma

Over time, organizations realized that the Lean and Six Sigma methodologies are highly complementary. Lean focuses on increasing process speed and efficiency by eliminating waste, while Six Sigma focuses on improving quality and effectiveness by reducing variation and defects. By combining them, Lean Six Sigma was created, a powerful, integrated methodology that leverages the strengths of both. Lean helps to identify areas of inefficiency, and Six Sigma provides the rigorous statistical tools to analyse and solve the root causes of the problems found.

This combined approach allows organizations to tackle a wider range of issues. A process can be efficient but not effective, or effective but not efficient. For example, a process might be very fast (Lean) but produce a high number of defects (poor Six Sigma). Conversely, a process might produce perfect quality (good Six Sigma) but be very slow and wasteful (poor Lean). Lean Six Sigma addresses both of these dimensions simultaneously. It aims to create processes that are not only fast and efficient but also consistent, predictable, and of high quality, ultimately leading to greater customer satisfaction and improved business performance.

The Specific Role of the Yellow Belt

The Lean Six Sigma Yellow Belt holds a crucial position within the continuous improvement ecosystem. While they are not expected to lead projects independently, they are the eyes and ears of the improvement program on the ground floor. A Yellow Belt is an employee who has been trained in the foundational principles and basic tools of Lean Six Sigma. Their primary role is to act as a valuable team member on improvement projects led by Green Belts or Black Belts. They bring a deep understanding of the day-to-day processes in their specific work area, which is invaluable for problem-solving.

Yellow Belts are responsible for applying basic Lean concepts, such as identifying the eight wastes, to their own work. They can help with data collection, participate in brainstorming sessions, and assist in implementing and sustaining process changes. They act as advocates for the continuous improvement culture, encouraging their colleagues to embrace new ways of working. By having a large number of employees trained at the Yellow Belt level, an organization can create a broad base of support and engagement for its Lean Six Sigma initiatives, ensuring that improvement is not just a top-down directive but a company-wide effort.

Why Start with a Yellow Belt Certification?

For individuals new to the world of process improvement, the Lean Six Sigma Yellow Belt certification is the ideal starting point. It provides a comprehensive yet accessible introduction to the core concepts, terminology, and tools of the methodology without being overwhelming. The training is typically shorter and less expensive than higher-level belt certifications, making it a low-risk way to explore the field. It equips individuals with practical skills that they can begin applying immediately in their daily work, allowing them to see the benefits of the methodology firsthand.

Starting with a Yellow Belt builds a solid foundation of knowledge that is essential for anyone considering advancing to higher levels, such as Green Belt or Black Belt. It allows you to understand the language of continuous improvement and participate meaningfully in project teams. For many professionals, the Yellow Belt level provides all the knowledge they need to be an effective contributor to their organization's improvement efforts. It demonstrates a proactive mindset and a commitment to quality and efficiency, which are highly valued by employers across all industries. This makes it a valuable credential for career development.

Introduction to the DMAIC Framework

At the heart of the Six Sigma methodology is the DMAIC framework, a systematic and data-driven approach to problem-solving. DMAIC is an acronym that stands for Define, Measure, Analyse, Improve, and Control. It is a five-phase, structured roadmap that guides teams through the process of improving an existing process. For a Lean Six Sigma Yellow Belt, understanding the purpose and activities of each phase is fundamental. While Yellow Belts may not lead a DMAIC project, they are essential participants who provide critical support and input at every stage.

The DMAIC framework ensures that solutions are based on data and analysis rather than guesswork. It prevents teams from jumping to conclusions and implementing fixes that do not address the true root cause of a problem. Each phase has a specific set of goals and a collection of tools that help the team achieve those goals. The process is logical and sequential; the output of one phase serves as the input for the next. This disciplined approach is what makes DMAIC so effective at delivering sustainable, measurable results. It provides a common language and a consistent methodology for improvement across an organization.

The Define Phase: Setting the Foundation

The Define phase is the first and arguably most important step in the DMAIC process. Its primary purpose is to clearly articulate the problem that needs to be solved, the goals of the project, and the scope of the effort. If this phase is not done well, the entire project can be misguided. A key activity in this phase is the development of a Project Charter. The charter is a formal document that serves as the project's contract. It includes the problem statement, business case, goals, scope, timeline, and a list of team members and stakeholders.

During this phase, the team also works to understand the Voice of the Customer. This involves identifying who the customers of the process are and what their requirements and expectations are. This ensures that the project's goals are aligned with delivering value to the customer. For a Yellow Belt, responsibilities in the Define phase might include helping to gather information for the project charter, participating in meetings to clarify the problem, and providing insights into the customer's experience based on their daily interactions. A well-defined project sets the stage for success in the subsequent phases.

The Measure Phase: Understanding Current Performance

Once the project is clearly defined, the team moves into the Measure phase. The goal of this phase is to collect data to establish a baseline of the process's current performance. This baseline serves as the starting point against which all future improvements will be measured. It is impossible to know if you have improved a process if you do not know how it was performing in the first place. The team begins by creating a detailed map of the current process, often using tools like a SIPOC diagram or a flowchart. This helps everyone understand the steps and sequence of the process.

Next, the team develops a data collection plan. This plan specifies what data needs to be collected, how it will be collected, who will collect it, and over what period. It is crucial to ensure that the data collected is accurate and reliable. Yellow Belts play a very active role in this phase. Given their familiarity with the day-to-day operations, they are often tasked with collecting the data. They might use check sheets, conduct time studies, or pull reports from systems. Their diligence and attention to detail in this phase are critical for providing the project with a solid, fact-based foundation.

The Analyse Phase: Identifying the Root Cause

With reliable data on the current process performance in hand, the team enters the Analyse phase. The objective of this phase is to use the data to identify, validate, and select the root cause or causes of the problem. This is a critical step that distinguishes the DMAIC framework from simple trial-and-error problem-solving. The team analyses the data collected in the Measure phase to look for patterns, trends, and clues that point towards the source of the issue. The goal is to move beyond the symptoms of the problem and uncover the underlying reason why it is occurring.

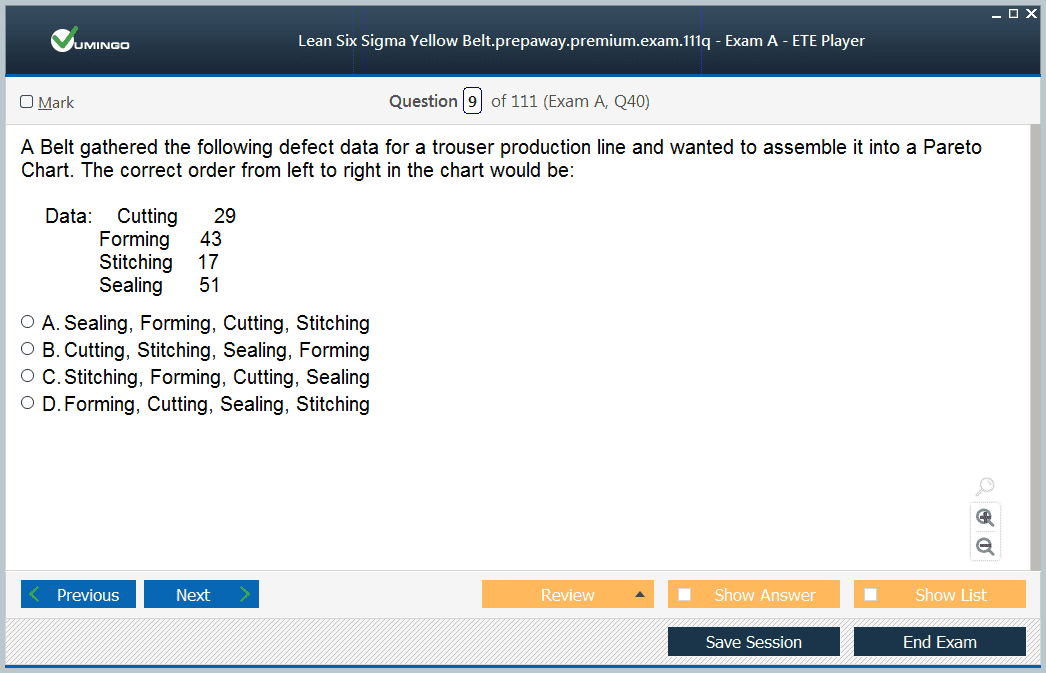

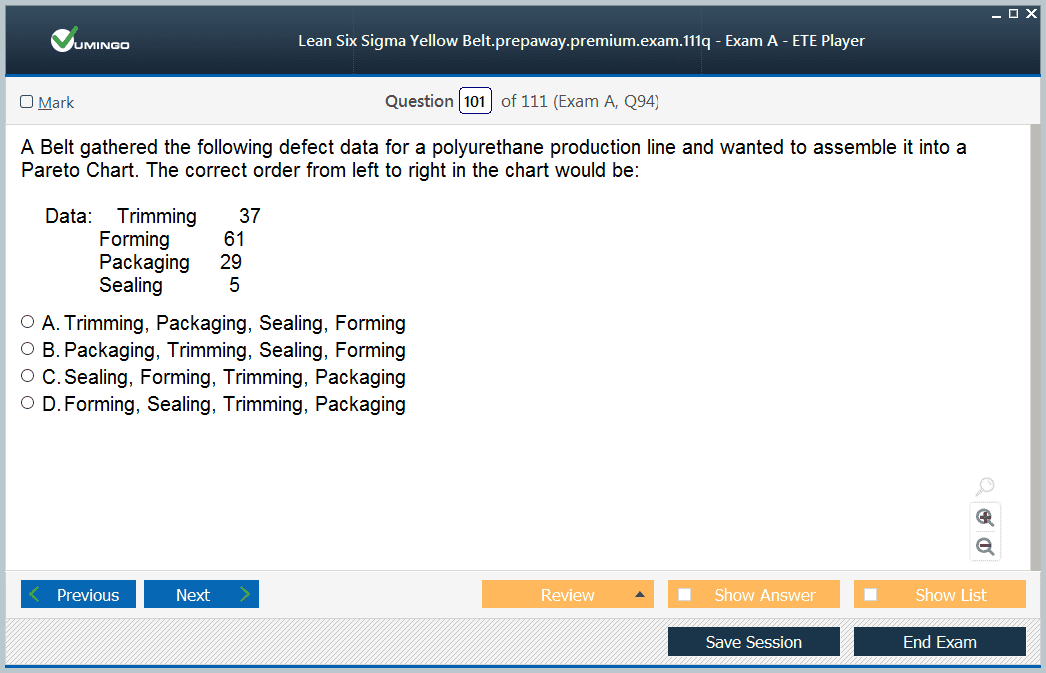

Several powerful but simple tools are used in this phase, many of which a Yellow Belt would be trained to use. The 5 Whys is a technique where the team repeatedly asks "Why?" to drill down to the root cause. A Fishbone Diagram, also known as an Ishikawa Diagram, is a visual tool used to brainstorm all the potential causes of a problem by categorizing them. Pareto Charts are used to identify the "vital few" causes that are responsible for the majority of the problem. A Yellow Belt's role is to participate in these brainstorming sessions and help use these tools to analyse the data.

The Improve Phase: Developing and Testing Solutions

After the team has successfully identified and verified the root cause of the problem, they are ready to move into the Improve phase. The goal of this phase is to brainstorm, evaluate, and implement solutions that are designed to address the root cause. It is important that the solutions are targeted specifically at the root cause identified in the Analyse phase. This ensures that the team is not just implementing temporary fixes but is making fundamental changes that will prevent the problem from recurring. The phase often begins with a brainstorming session to generate a wide range of potential solutions.

Once a list of potential solutions has been created, the team must evaluate them to select the best one. This might involve using a solution selection matrix to weigh the options against criteria such as cost, effort, and impact. Before a full-scale rollout, the chosen solution is often tested on a smaller scale in a pilot study. This allows the team to verify that the solution works as intended and to identify any unforeseen consequences. Yellow Belts can contribute by participating in brainstorming, providing practical feedback on the feasibility of proposed solutions, and assisting with the implementation of the pilot test.

The Control Phase: Sustaining the Gains

The final phase of the DMAIC framework is the Control phase. The purpose of this phase is to ensure that the improvements made are sustained over the long term. It is not enough to simply fix the problem; the team must put measures in place to prevent the process from reverting to its old, inefficient ways. A key activity in this phase is the development of a Control Plan. This plan documents the new process, outlines the key metrics that need to be monitored, and specifies the actions to be taken if the process performance starts to degrade.

Another important activity is the standardization of the new process. This often involves updating or creating new Standard Operating Procedures, work instructions, and training materials. This ensures that everyone is following the new and improved process consistently. The project is then officially closed, and the ownership of the new process is handed back to the process owner and the team that operates it daily. A Yellow Belt's role in this phase is crucial. They help to document the new procedures, train their colleagues, and are often responsible for the ongoing monitoring of the process performance as part of their regular duties.

The Iterative Nature of DMAIC

While the DMAIC framework is presented as a linear, five-step process, it is important to understand that it can be iterative in practice. It is not uncommon for a team to gather more information in a later phase that requires them to revisit an earlier one. For example, during the Analyse phase, the team might realize that they did not collect the right data in the Measure phase. They would then need to loop back to the Measure phase to collect the necessary information before they can proceed. This flexibility is a strength of the framework.

This iterative nature ensures that the project stays on the right track and that decisions are always based on the best available information. It encourages a cycle of learning and discovery. A Yellow Belt participating in a DMAIC project should be aware of this and be prepared to be flexible. The goal is not to rigidly follow the steps but to use the framework as a guide to systematically and effectively solve the problem. The structured yet iterative approach of DMAIC is what has made it one of the most successful and widely adopted problem-solving methodologies in the world.

The Importance of a Process Improvement Toolkit

A Lean Six Sigma Yellow Belt is equipped with a foundational toolkit of simple yet powerful techniques for analysing and improving processes. These tools are the practical application of the principles behind the methodology. They provide a structured way to visualize processes, collect and analyse data, and identify the root causes of problems. While a Yellow Belt is not expected to master complex statistical analysis, their proficiency with these basic tools makes them an invaluable asset to any improvement team. These tools provide a common language that facilitates clear communication and effective collaboration during a project.

The toolkit is designed to be versatile and applicable across a wide range of industries and types of processes. Whether the problem is related to reducing patient wait times in a hospital, minimizing defects in a manufacturing line, or streamlining an invoicing process in an office, these fundamental tools can be used to bring clarity and structure to the problem-solving effort. For a Yellow Belt, learning to use these tools is a key part of their training. It empowers them to move beyond simply pointing out problems and gives them the means to contribute to developing effective solutions.

Process Mapping: Visualizing the Workflow

Process mapping is one of the most fundamental tools in the Lean Six Sigma toolkit. It is the practice of creating a visual representation of a process, showing the sequence of steps and decisions from beginning to end. A process map, or flowchart, helps the entire team to develop a shared understanding of how the process currently works, not how it is supposed to work. This visual clarity often immediately reveals areas of complexity, redundancy, or potential bottlenecks that are not obvious from a simple written description of the process.

There are several types of process maps, but a Yellow Belt will most commonly use a simple flowchart. Another useful tool is the SIPOC diagram. SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. It is a high-level process map that provides a bird's-eye view of the process and its context. It helps to define the scope of the project and identify key stakeholders. Yellow Belts often assist in creating these maps by providing their detailed knowledge of the process steps, as they are the ones who perform the work every day.

Root Cause Analysis with the 5 Whys

The 5 Whys is a simple but remarkably effective root cause analysis technique. Its premise is that by repeatedly asking the question "Why?" in response to a problem, you can peel back the layers of symptoms and uncover the underlying root cause. The "5" is just a guideline; the key is to continue asking "Why?" until you arrive at a cause that, if addressed, will prevent the problem from recurring. This technique helps teams to avoid the common trap of addressing the symptoms of a problem rather than its true source.

For example, if the problem is that a machine has stopped working, the first "Why?" might reveal that a fuse has blown. The second "Why?" might find that the fuse blew because the machine was overloaded. The third "Why?" could discover that the machine was overloaded because the bearing was not properly lubricated. The fourth "Why?" might show that the bearing was not lubricated because the automated lubrication pump is not working. The fifth "Why?" could reveal that the pump is not working because its shaft is worn. The 5 Whys is a perfect tool for a Yellow Belt as it requires no statistical analysis, only a curious and persistent mindset.

The Fishbone Diagram for Brainstorming Causes

The Fishbone Diagram, also known as an Ishikawa Diagram or a Cause-and-Effect Diagram, is a visual tool used to brainstorm and organize the potential causes of a problem. The diagram is drawn to resemble the skeleton of a fish. The "head" of the fish represents the problem or effect, and the "bones" extending from the spine represent different categories of potential causes. This structure helps the team to think systematically and ensure that they consider a wide range of possibilities before jumping to conclusions.

The categories used for the bones can be adapted to any industry, but common ones, particularly in manufacturing, are the 6 M's: Manpower, Method, Machine, Material, Measurement, and Mother Nature (Environment). For service industries, categories might include People, Process, Policies, and Plant. During a brainstorming session, the team suggests potential causes, and they are placed on the appropriate bone of the diagram. A Yellow Belt's role is to actively participate in these sessions, contributing their ideas and firsthand knowledge of the process to help populate the diagram.

Using Pareto Charts to Prioritize Efforts

The Pareto Chart is a simple type of bar chart that is used to prioritize problems or causes. It is based on the Pareto Principle, also known as the 80/20 rule, which states that for many events, roughly 80% of the effects come from 20% of the causes. A Pareto Chart displays the causes of a problem in descending order of their frequency or impact. A line graph is typically overlaid on the bar chart to show the cumulative percentage. This visual representation makes it easy to identify the "vital few" causes that are responsible for the majority of the problem.

By using a Pareto Chart, a team can focus its limited time and resources on addressing the most significant causes, rather than trying to tackle everything at once. This ensures that their improvement efforts will have the maximum possible impact. For example, if a team is analysing customer complaints, a Pareto Chart might show that 80% of the complaints are related to just two or three specific issues. A Yellow Belt might be responsible for collecting the data needed to create the Pareto Chart, such as categorizing and counting the types of defects found in a process.

Lean Tools for Workplace Organization: 5S

5S is a Lean tool focused on creating a clean, organized, and efficient workplace. The name comes from five Japanese words that describe the steps of the methodology: Seiri (Sort), Seiton (Set in Order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain). The first step, Sort, involves going through all the items in a work area and removing anything that is not needed. Set in Order is the process of arranging the necessary items so that they are easy to find, use, and return. Shine involves cleaning the work area.

The fourth step, Standardize, is about creating rules and procedures to ensure that the first three S's are maintained consistently. This might include creating checklists or assigning regular cleaning duties. The final step, Sustain, is the most challenging. It involves making 5S a part of the daily culture and ensuring that the new standards are followed over the long term. 5S is a foundational Lean practice that Yellow Belts can champion in their own work areas. It reduces waste, improves safety, and creates a more pleasant and productive work environment for everyone.

Poka-Yoke: The Concept of Mistake-Proofing

Poka-Yoke is a Japanese term that means "mistake-proofing" or "inadvertent error prevention." It is a Lean technique that focuses on designing processes and equipment in a way that makes it impossible for errors to occur. The goal is to prevent defects at the source, rather than relying on inspection to catch them later. Poka-Yoke devices or methods are often very simple and inexpensive to implement, yet they can be incredibly effective at improving quality. They are based on the principle that human errors are inevitable, but they do not have to result in defects.

There are two main types of Poka-Yoke. The first is the control method, which physically prevents a mistake from being made. For example, a USB cable can only be inserted one way. The second is the warning method, which alerts the operator when a mistake has been made, allowing them to correct it immediately. An example of this is a car that beeps if you leave the headlights on. Yellow Belts, with their intimate knowledge of their work processes, are often in the best position to identify opportunities for implementing simple Poka-Yoke solutions to prevent common errors.

Daily Responsibilities of a Lean Six Sigma Yellow Belt

The responsibilities of a Lean Six Sigma Yellow Belt extend beyond their participation in formal projects. They are expected to apply the continuous improvement mindset to their everyday work. A key responsibility is to be observant and actively identify opportunities for improvement within their own work area. This involves recognizing the eight wastes of Lean, such as unnecessary steps, delays, or rework, in their daily tasks. They are encouraged to not just accept inefficiencies as "the way things have always been done" but to question them and suggest better ways of working.

Another daily responsibility is to promote the culture of continuous improvement among their peers. By demonstrating the benefits of using Lean Six Sigma principles in their own work, they can inspire their colleagues to adopt a similar mindset. They might lead informal huddles to discuss process issues or champion the use of simple tools like 5S for workplace organization. They act as a local resource for their team members, answering basic questions about the methodology and encouraging participation in improvement initiatives. This grassroots advocacy is vital for making continuous improvement a part of the organization's DNA.

The Yellow Belt's Role in a Formal Project Team

Within the structure of a formal DMAIC project, the Yellow Belt plays a critical support role. While the project is typically led by a Green Belt or a Black Belt, the Yellow Belt serves as a Subject Matter Expert for the specific process being improved. Their deep, practical knowledge of how the work actually gets done is an invaluable resource for the project leader, who may not have the same level of hands-on experience. They help to bridge the gap between the high-level methodology and the practical realities of the workplace.

A Yellow Belt's specific tasks on a project will vary depending on the phase. In the Define phase, they help to scope the problem and provide input for the project charter. In the Measure phase, they are often on the front lines, collecting data and helping to create process maps. During the Analyse phase, they participate in brainstorming sessions to identify potential root causes. In the Improve phase, they offer feedback on proposed solutions and assist with pilot testing. Finally, in the Control phase, they help to document the new process and train their colleagues, ensuring a smooth transition.

Interaction with Other Belt Levels

Effective collaboration between the different belt levels is essential for the success of a Lean Six Sigma program. The Yellow Belt's interaction with Green and Black Belts is one of partnership and mentorship. The Yellow Belt provides the detailed process knowledge, while the Green or Black Belt provides the deep methodological expertise and project leadership. The project leader relies on the Yellow Belt for accurate data and honest feedback about the practicality of potential changes. In return, the project leader mentors the Yellow Belt, helping them to develop their problem-solving skills and deepen their understanding of the tools.

The Yellow Belt also interacts with the Project Champion, who is typically a senior manager with the authority to approve the project and remove organizational barriers. The Yellow Belt's role in this interaction is to help provide the Champion with the data and information they need to make informed decisions and to stay updated on the project's progress. By working effectively with all these different stakeholders, the Yellow Belt ensures that they are a well-integrated and respected member of the project team, contributing significantly to its overall success.

Case Study: A Yellow Belt in a Healthcare Setting

Imagine a Yellow Belt working as an administrative assistant in a busy outpatient clinic. The clinic is facing a problem with long patient wait times, leading to poor patient satisfaction scores. A Green Belt initiates a DMAIC project to address this issue, and the administrative assistant, as a certified Yellow Belt, is asked to join the project team. In the Measure phase, the Yellow Belt is tasked with tracking the time patients spend at each stage of their visit, from check-in to check-out. They create a simple check sheet to collect this data over a two-week period.

In the Analyse phase, the team creates a Pareto Chart with the data collected by the Yellow Belt. They discover that 80% of the total wait time is occurring between the patient's arrival and the moment they are called back to an exam room. The Yellow Belt participates in a brainstorming session and suggests that a major cause is the inefficient process for preparing patient charts. In the Improve phase, the team redesigns the check-in process based on the Yellow Belt's suggestions. After implementing the changes, patient wait times are reduced by 50%, demonstrating the direct impact of the Yellow Belt's contribution.

Case Study: A Yellow Belt in a Manufacturing Plant

Consider a Yellow Belt who works as a machine operator in a manufacturing plant. The production line is experiencing a high rate of scrap material, which is increasing costs. A Black Belt launches a project to reduce the scrap rate, and the machine operator joins the team. During the Analyse phase, the team uses a Fishbone Diagram to brainstorm the potential causes of the scrap. The Yellow Belt, drawing on their daily experience, suggests that the machine settings often drift out of specification during a production run, which is a major cause of defects.

The team validates this with data and moves to the Improve phase. The Yellow Belt suggests a simple mistake-proofing solution. They propose creating a colour-coded template that can be placed over the machine's control panel, making it easy for operators to see if the settings are within the correct range at a glance. They also help to develop a simple checklist for operators to use at the beginning of each shift to verify the settings. This low-cost solution is implemented, and the scrap rate drops by 70%. This case highlights how a Yellow Belt's practical insights can lead to simple, effective solutions.

Contributing to a Culture of Continuous Improvement

The organizational impact of Yellow Belts goes far beyond the results of individual projects. By training a significant portion of the workforce at the Yellow Belt level, an organization can create a powerful, self-sustaining culture of continuous improvement. When employees at all levels are equipped with the language and tools to identify and solve problems, improvement becomes an everyday activity rather than a special event. Yellow Belts act as catalysts for this cultural shift. They lead by example, demonstrating a proactive approach to problem-solving in their own work.

This widespread engagement has numerous benefits. It increases employee morale and empowerment, as people feel that they have a voice and can make a meaningful impact on their work environment. It accelerates the pace of improvement, as small problems are identified and fixed quickly at the local level before they can become larger issues. It also builds a pipeline of talent for the continuous improvement program, as some Yellow Belts will become inspired to pursue higher-level certifications and take on greater leadership roles. The collective impact of a well-trained Yellow Belt workforce can be truly transformational for an organization.

The Organizational Benefits of a Yellow Belt Program

Investing in a Lean Six Sigma Yellow Belt training program for employees yields substantial returns for an organization. The most direct benefit is the financial impact of the improvement projects that Yellow Belts participate in. These projects lead to measurable reductions in costs, increases in revenue, and improvements in efficiency. By eliminating waste and defects, the organization can produce its goods or services at a lower cost and with higher quality, which leads to improved profitability and a stronger competitive position in the marketplace.

Beyond the financial benefits, a Yellow Belt program enhances the organization's problem-solving capabilities. It creates a common framework and language for improvement, which breaks down silos between departments and fosters better cross-functional collaboration. It also leads to increased customer satisfaction. By focusing on improving processes, the organization is better able to meet and exceed customer expectations for quality, speed, and service. Finally, as mentioned, it boosts employee engagement and retention. Employees who feel valued and empowered are more likely to be satisfied with their jobs and committed to the organization's success.

Is the Yellow Belt Certification a Worthwhile Investment?

For any professional looking to enhance their skills and career prospects, the Lean Six Sigma Yellow Belt certification is undoubtedly a worthwhile investment. It is a highly respected credential that signals to employers a commitment to quality, efficiency, and data-driven decision-making. The investment in terms of time and cost for a Yellow Belt certification is relatively low, especially when compared to the significant return it can provide. The skills learned are not abstract theories but practical tools that can be applied immediately to make a tangible impact in any role.

The certification provides a clear and structured introduction to the world of process improvement. It is an ideal entry point for those who are curious about the field but not yet ready to commit to the more intensive training required for a Green or Black Belt. It enhances your resume, making you a more attractive candidate in a competitive job market. For those already employed, it provides the skills needed to contribute more effectively to their team and organization, which can lead to greater job satisfaction and opportunities for advancement. The value lies in its practicality and its universal applicability across industries.

Average Salary and Career Prospects

While the Yellow Belt is an entry-level certification, it can have a positive impact on salary and career opportunities. It is not typically a standalone job requirement but rather a valuable skill that complements a primary role. Professionals in fields such as operations, quality assurance, project management, and logistics often find that a Yellow Belt certification enhances their earning potential. It demonstrates a level of process improvement knowledge that sets them apart from their peers. The salary impact will vary based on industry, location, and the individual's primary job function.

In North America and Europe, a professional with a Yellow Belt certification in a relevant role might see a modest but meaningful increase in their salary compared to someone without it. The real value, however, comes from the career opportunities it unlocks. The certification can make you a stronger candidate for internal promotions or for new jobs that require a foundational understanding of process improvement. It shows that you have the skills to support improvement initiatives, which is a highly sought-after attribute for roles like Process Technician, Quality Analyst, or Operations Coordinator.

The Career Path: From Yellow Belt to Master Black Belt

The Lean Six Sigma Yellow Belt certification is the first step on a well-defined career path in process improvement. For those who discover a passion for this work, the path to advancement is clear. The next level is the Green Belt. To become a Green Belt, an individual must build on their Yellow Belt knowledge, learn more advanced statistical tools, and successfully lead a small-scale improvement project. Green Belts are often part-time process improvement leaders who spend a portion of their time on their regular duties and a portion on leading projects.

From Green Belt, the path leads to Black Belt. A Black Belt is a full-time expert in Lean Six Sigma who leads complex, high-impact, cross-functional projects. They have a deep mastery of advanced statistical methods and act as mentors to Green Belts. The final step on the path is the Master Black Belt. A Master Black Belt is a strategic leader who is responsible for deploying the Lean Six Sigma program across the entire organization. They train and mentor Black Belts and work with senior leadership to align the improvement strategy with the overall business goals.

Applying Yellow Belt Skills Across Different Industries

One of the greatest strengths of the Lean Six Sigma methodology is its versatility. The principles of eliminating waste, reducing variation, and focusing on the customer are universal and can be applied to any type of process in any industry. A Yellow Belt certification is therefore a highly portable credential that is valuable in a wide range of sectors. In manufacturing, a Yellow Belt can help to reduce defects and improve production flow. In healthcare, they can contribute to projects that reduce patient wait times, prevent medical errors, and improve the patient experience.

In the finance and banking industry, a Yellow Belt can help to streamline loan application processes or reduce errors in transaction processing. In logistics and supply chain management, they can identify ways to reduce transportation waste and improve inventory management. In the IT sector, their skills can be applied to software development processes to reduce bugs and improve delivery times. No matter the industry, the ability to look at a process critically, identify inefficiencies, and contribute to a structured improvement effort is a highly valuable skill.

The Yellow Belt and the Future of Work

In an era of rapid technological change and digital transformation, the skills provided by a Lean Six Sigma Yellow Belt certification are more relevant than ever. As automation and artificial intelligence handle more routine tasks, the uniquely human skills of critical thinking, problem-solving, and collaboration become increasingly important. The DMAIC framework is essentially a structured method for critical thinking. It teaches individuals how to approach problems logically and systematically, a skill that is timeless and will always be in high demand.

Furthermore, Lean Six Sigma principles align very well with other modern management methodologies like Agile. Both philosophies emphasize customer value, iterative improvement, and empowering teams. An individual with a Yellow Belt certification is well-positioned to work effectively in an Agile environment, as they already have a foundational understanding of process flow and continuous improvement. As organizations continue to evolve, the ability to adapt, learn, and improve will be the key to success, and a Yellow Belt certification is an excellent way to demonstrate that ability.

How to Get Certified

The process of obtaining a Lean Six Sigma Yellow Belt certification is designed to be accessible. There are numerous training providers that offer Yellow Belt courses, both in-person and online. The training typically covers the foundational principles of Lean and Six Sigma, the DMAIC framework, and the basic improvement tools. The duration of the training can range from a one-day workshop to a more comprehensive course spread over several weeks. Online courses offer the flexibility to learn at your own pace, which is ideal for busy professionals.

Upon completion of the training, there is usually an examination to test the individual's understanding of the concepts. The exam is typically multiple-choice and covers the material presented in the course. Some certification bodies may also require the completion of a small, simulated project to demonstrate the practical application of the knowledge. Once the training and exam requirements are met, the individual is awarded their Lean Six Sigma Yellow Belt certification. It is a straightforward process that provides a valuable and recognized credential.

Conclusion

In conclusion, the Lean Six Sigma Yellow Belt certification is a powerful and practical first step into the world of continuous improvement. It provides a solid foundation of knowledge and a toolkit of essential techniques that can be applied in any industry and any role. It empowers individuals to become active participants in making their workplaces more efficient, effective, and customer-focused. The certification enhances problem-solving skills, boosts career opportunities, and fosters a culture of positive change.

Whether your goal is to advance in your current career, change industries, or simply become a more effective and valuable employee, the Yellow Belt certification is a smart investment. It lays the groundwork for potential advancement to higher belt levels while providing immediate, tangible benefits in your daily work. In a world that demands constant improvement and adaptation, the skills learned as a Lean Six Sigma Yellow Belt are not just useful; they are essential for long-term professional success.

Lean Six Sigma Yellow Belt certification practice test questions and answers, training course, study guide are uploaded in ETE files format by real users. Study and pass Six Sigma Lean Six Sigma Yellow Belt certification exam dumps & practice test questions and answers are the best available resource to help students pass at the first attempt.