- Home

- API Certifications

- API-580 Risk Based Inspection Dumps

Pass API API-580 Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

API-580 Premium File

- Premium File 137 Questions & Answers. Last Update: Feb 04, 2026

Whats Included:

- Latest Questions

- 100% Accurate Answers

- Fast Exam Updates

Last Week Results!

All API API-580 certification exam dumps, study guide, training courses are Prepared by industry experts. PrepAway's ETE files povide the API-580 Risk Based Inspection practice test questions and answers & exam dumps, study guide and training courses help you study and pass hassle-free!

Risk-Based Inspection Made Simple: Your Complete Guide to API -580

The API-580 exam evaluates a professional’s proficiency in understanding, implementing, and managing risk-based inspection programs in industrial settings. Risk-based inspection focuses on assessing both the probability of failure and the consequence of failure for process equipment, guiding inspection priorities based on risk assessment rather than routine schedules. This approach ensures that resources are allocated efficiently, equipment integrity is maintained, and operational reliability is maximized. Candidates are tested on their ability to apply theoretical principles, interpret operational data, and develop actionable inspection strategies in line with industry standards.

The exam emphasizes the importance of understanding the life cycle of industrial equipment. Knowledge of how materials degrade over time due to environmental factors, operational stress, chemical exposure, and mechanical wear is critical. Professionals must be able to assess damage mechanisms such as corrosion, cracking, erosion, fatigue, oxidation, sulfidation, and other forms of degradation. The ability to identify how these mechanisms interact, influence equipment reliability, and affect safety outcomes forms a core part of the examination framework.

Core Concepts and Frameworks in Risk-Based Inspection

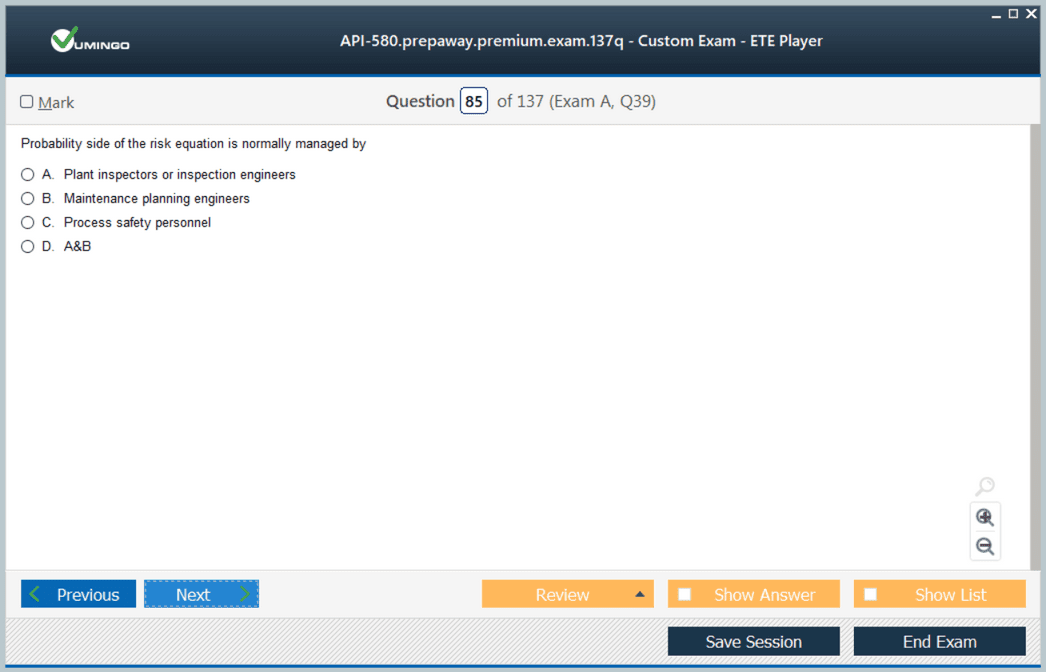

A foundational element of API-580 preparation is mastering the framework that governs risk-based inspection. Candidates must understand the process of evaluating equipment risk using a structured methodology that combines probability of failure, consequence of failure, and inspection planning. Probability of failure involves assessing the likelihood that a component or system will fail within a defined period, influenced by factors such as equipment age, material selection, operational history, environmental exposure, and past incidents. Consequence of failure evaluates the impact of equipment failure, including safety hazards, environmental damage, production losses, and financial implications.

Understanding how these two factors combine to produce a risk profile is essential for prioritizing inspection and maintenance activities. Candidates must be able to interpret risk matrices, categorize risk levels, and determine appropriate inspection intervals based on both quantitative and qualitative assessments. Knowledge of these principles enables professionals to focus on the most critical assets, anticipate potential failures, and implement preventive measures that reduce unplanned downtime and operational hazards.

Probability of Failure Analysis

Probability of failure analysis is a central component of the API-580 exam. Candidates must recognize how various operational and material factors influence the likelihood of equipment degradation. This includes evaluating the effects of age, wear, exposure to corrosive substances, temperature variations, and mechanical stress. Older equipment typically exhibits higher probabilities of failure, making accurate assessment and historical data analysis essential. Candidates are expected to understand methods for tracking and updating probability metrics to reflect changing conditions, modifications, or maintenance interventions.

The exam also tests knowledge of failure prediction techniques. Professionals must be able to assess historical inspection data, identify trends in material degradation, and determine which components are most at risk. Recognizing patterns in operational behavior and correlating these with damage mechanisms allows for informed predictions about potential failures. Scenario-based questions often present complex combinations of variables, requiring candidates to evaluate probability across multiple interacting factors.

Consequence of Failure Analysis

Consequence of failure analysis complements probability assessments by evaluating the potential outcomes of equipment failure. Candidates must be able to categorize consequences from minor operational disruptions to catastrophic incidents, taking into account personal safety, environmental impact, production loss, and financial costs. Quantitative assessments may involve estimating repair costs, downtime, and potential revenue loss, while qualitative assessments categorize risk levels based on severity.

A deep understanding of consequence assessment allows professionals to prioritize inspection and maintenance efforts effectively. The exam tests the ability to interpret consequence matrices, integrate multiple impact factors, and make recommendations that mitigate risk while maintaining operational efficiency. Candidates must also consider secondary effects, such as how a single failure can influence other systems, creating cascading risks that require strategic planning.

Identification of Damage Mechanisms and Failure Modes

A key aspect of API-580 preparation involves identifying damage mechanisms and understanding failure modes. Damage mechanisms are the underlying processes that cause equipment degradation, such as corrosion, cracking, erosion, and high-temperature effects. Failure modes describe the way in which equipment can fail, including leaks, ruptures, or structural collapses. Candidates must be able to link observed or predicted damage mechanisms with specific failure modes to develop actionable inspection strategies.

Understanding the interaction between multiple damage mechanisms is critical. For instance, high-temperature operation may accelerate corrosion, while mechanical vibration may exacerbate fatigue cracking. Candidates must analyze these interactions, assess their potential impact on equipment integrity, and determine appropriate preventive or corrective actions. Scenario-based questions frequently test the ability to synthesize knowledge from various domains to identify both primary and secondary failure mechanisms.

Data Collection and Information Management

Effective risk-based inspection relies heavily on accurate data and comprehensive information management. Candidates are expected to understand the sources of relevant data, including design documents, operational records, maintenance logs, inspection reports, and historical performance data. Proper data collection and management ensure that probability and consequence assessments are reliable and that inspection plans are based on accurate, up-to-date information.

The exam emphasizes the importance of personnel qualifications, data validation, and proper documentation practices. Candidates must demonstrate knowledge of how to organize, store, and analyze inspection and operational data, ensuring consistency and traceability. Understanding how to integrate multiple data sources to produce a coherent risk assessment is a central skill evaluated during the exam.

Team Roles and Collaborative Risk Assessment

Risk-based inspection is a collaborative process requiring input from a multidisciplinary team. Candidates are tested on their understanding of team structures and the roles of each member in conducting risk assessments. Typical team members include equipment inspectors, corrosion specialists, process engineers, operations and maintenance personnel, safety experts, risk analysts, and financial or business personnel.

The exam assesses the ability to coordinate team efforts, assign responsibilities, and integrate diverse expertise into a unified assessment. Effective communication and collaboration are essential for ensuring that all relevant factors are considered and that inspection and maintenance plans are both practical and technically sound. Candidates must also understand how to lead or participate in decision-making processes, balancing risk, cost, and operational priorities.

Inspection Planning and Strategy Development

Inspection planning under API-580 involves translating risk assessments into practical, actionable strategies. Candidates must understand how to determine inspection intervals, select appropriate inspection techniques, and prioritize high-risk equipment. Scenario-based questions test the ability to apply probability and consequence assessments to develop inspection plans that optimize resource allocation and minimize operational disruptions.

Candidates are expected to evaluate the suitability of different inspection methods, including visual inspection, ultrasonic testing, radiography, eddy current testing, and other non-destructive techniques. Understanding the strengths, limitations, and appropriate applications of each method is essential for effective inspection planning. The exam also tests knowledge of integrating inspection results into continuous risk management cycles, ensuring that evolving equipment conditions are accounted for in future planning.

Limitations and Considerations in Risk-Based Inspection

The API-580 exam also examines candidates’ understanding of the limitations inherent in risk-based inspection programs. Inaccurate or missing data can lead to flawed risk assessments. Poor design, improper installation, or operation beyond recommended limits may create risks that RBI cannot mitigate alone. Additionally, ineffective execution of inspection plans, insufficiently trained personnel, poor teamwork, or failure to act on inspection findings can undermine risk reduction efforts.

Candidates must demonstrate the ability to recognize these limitations, consider them in planning and decision-making, and recommend corrective measures when necessary. Understanding the boundaries of risk-based inspection ensures that professionals can apply RBI methodologies effectively while addressing factors that fall outside the scope of the standard.

Long-Term Benefits and Application of API-580 Knowledge

Mastery of API-580 principles provides significant benefits for professional practice. Effective risk-based inspection allows organizations to focus resources on the highest-risk equipment, reduce equipment failures, improve reliability, optimize maintenance costs, and maintain safe operational conditions. Knowledge gained during preparation for the exam supports proactive planning, continuous monitoring, and evidence-based decision-making.

Candidates are expected to understand how to apply these principles in real-world settings, including developing risk matrices, integrating inspection results into maintenance schedules, and evaluating operational changes. Long-term application of API-580 knowledge enhances the ability to manage complex industrial systems, ensure compliance with safety standards, and improve overall equipment performance.

Preparing for the API-580 Exam

Preparation for the API-580 exam requires both theoretical study and practical application. Candidates must familiarize themselves with the structure and content of the standard, including probability and consequence assessment, damage mechanisms, inspection planning, and risk management methodologies. Scenario-based practice is particularly important, as the exam tests the ability to apply knowledge in realistic industrial situations.

Structured study, combined with review of case studies and operational data, enhances understanding and retention. Candidates benefit from hands-on experience in industrial inspections, collaborative risk assessment exercises, and simulated problem-solving under timed conditions. This combination of theoretical knowledge, practical application, and analytical skill development ensures readiness for the exam and the ability to implement risk-based inspection programs effectively in professional practice.

Advanced Risk Assessment Techniques

In the API-580 exam, candidates are evaluated on their ability to conduct advanced risk assessments that combine probability of failure and consequence of failure in a comprehensive framework. Understanding how to weigh multiple variables simultaneously is critical for creating effective inspection plans. Risk assessment requires evaluating equipment age, operating conditions, environmental exposure, historical performance, and material properties. Professionals must be able to integrate these factors to determine the relative risk of each component and prioritize inspection and maintenance actions accordingly.

Candidates must also understand the methods for quantifying probability of failure, which may involve historical data analysis, statistical models, and empirical correlations. High-risk components often exhibit patterns of degradation that can be predicted through careful monitoring and analysis. The exam tests the ability to identify these trends and use them to inform inspection intervals. Likewise, assessing the consequence of failure requires evaluating potential safety hazards, production impacts, environmental risks, and financial losses. Scenario-based questions challenge candidates to synthesize this information into actionable strategies.

Evaluating Damage Mechanisms in Depth

The API-580 exam emphasizes in-depth understanding of damage mechanisms affecting industrial equipment. Candidates must recognize that degradation often occurs due to multiple interacting factors, such as chemical attack, mechanical stress, thermal cycling, and environmental conditions. Each mechanism can act independently or synergistically to accelerate equipment failure. Identifying these mechanisms is essential for designing effective inspection and mitigation plans.

Candidates are expected to classify damage mechanisms according to their nature, severity, and progression rate. Corrosion can be uniform, localized, or pitting, each with unique implications for structural integrity. Cracking may occur due to fatigue, stress corrosion, or hydrogen embrittlement, and candidates must differentiate these causes. Erosion and abrasion result from fluid flow or particle interaction, often acting in combination with chemical or thermal factors. Recognizing these interactions and predicting their effects on equipment performance is a central skill evaluated in the exam.

Inspection Methodologies and Techniques

A critical component of API-580 preparation involves mastering inspection methodologies and non-destructive testing techniques. Candidates must understand the principles, applications, advantages, and limitations of various inspection methods, including visual inspection, ultrasonic testing, radiography, eddy current testing, magnetic particle inspection, and other specialized techniques. Selecting the most appropriate method requires understanding the material, damage mechanism, and expected failure mode.

The exam evaluates the ability to plan inspection programs based on risk assessment. This includes determining the type of inspection required, the frequency of evaluation, and the personnel qualifications necessary to perform each task. Candidates must also demonstrate the ability to interpret inspection data, identify trends in equipment degradation, and make informed recommendations for maintenance, repair, or replacement. Scenario-based questions often simulate real-world conditions where multiple damage mechanisms may be present, testing analytical reasoning and decision-making skills.

Role of Data and Documentation

Effective risk-based inspection relies on comprehensive data collection and meticulous documentation. Candidates must be familiar with the sources of data, which include design specifications, maintenance records, operational logs, inspection reports, and historical failure information. Proper organization, storage, and validation of data are crucial for accurate risk assessment and effective inspection planning.

The API-580 exam tests the ability to analyze data critically, identify gaps or inconsistencies, and determine how these might affect risk evaluation. Candidates must also understand the importance of documenting inspection findings, maintenance actions, and any deviations from recommended procedures. Maintaining accurate records ensures traceability, supports regulatory compliance, and provides a foundation for continuous improvement in inspection and maintenance programs.

Multidisciplinary Team Collaboration

Risk-based inspection is inherently a collaborative process, requiring input from professionals across multiple disciplines. The API-580 exam assesses candidates’ understanding of team roles, including equipment inspectors, corrosion specialists, process engineers, operations personnel, safety officers, risk analysts, and financial experts. Each member contributes unique expertise to ensure that risk assessments are comprehensive and inspection plans are practical and effective.

Candidates must demonstrate the ability to facilitate communication and coordination among team members, integrating diverse perspectives into a unified risk management strategy. Effective collaboration ensures that all potential hazards, operational constraints, and cost considerations are accounted for. Scenario-based questions often test the candidate’s ability to manage team dynamics, assign responsibilities, and develop consensus-based inspection plans that optimize safety and operational efficiency.

Scenario-Based Problem Solving

The API-580 exam heavily emphasizes scenario-based problem solving, requiring candidates to apply theoretical knowledge in practical contexts. Candidates may be presented with complex operational scenarios involving multiple equipment types, varying environmental conditions, and diverse damage mechanisms. They are required to analyze these scenarios, identify the most critical risks, and recommend inspection strategies that prioritize safety and operational continuity.

Scenario analysis involves decomposing complex situations into manageable components, evaluating probability and consequence for each element, and considering the interactions among multiple factors. Candidates must also integrate historical data, operational trends, and material characteristics to develop a comprehensive understanding of potential failure modes. Practicing scenario-based problem solving enhances critical thinking and analytical skills, ensuring candidates are prepared for the real-world challenges presented in the exam.

Advanced Risk Matrices and Prioritization

Understanding and applying risk matrices is an essential skill for API-580 candidates. Risk matrices combine probability and consequence to categorize equipment into different risk levels, guiding inspection and maintenance priorities. Candidates must be able to interpret these matrices, adjust risk thresholds based on operational context, and allocate resources effectively to address the highest-risk components first.

The exam evaluates the ability to apply both quantitative and qualitative approaches to risk assessment. Quantitative methods may involve statistical analysis, historical failure data, and predictive modeling, while qualitative approaches rely on expert judgment and experience-based categorization. Candidates are expected to understand the strengths and limitations of each approach and apply them appropriately to scenario-based questions.

Lifecycle Analysis and Equipment Degradation

A core aspect of API-580 knowledge is understanding the lifecycle of industrial equipment and how degradation evolves over time. Candidates must evaluate how material properties, operational conditions, and environmental factors influence equipment performance throughout its service life. Recognizing the stages of equipment aging and predicting potential failure points are central to developing effective inspection and maintenance plans.

The exam emphasizes the ability to integrate lifecycle analysis with risk assessment and inspection planning. Candidates must understand how early signs of damage, such as localized corrosion or micro-cracking, can progress into significant failures if not addressed. Predictive analysis and continuous monitoring are key to mitigating these risks and ensuring that inspection strategies remain aligned with evolving equipment conditions.

Integrating RBI with Maintenance Programs

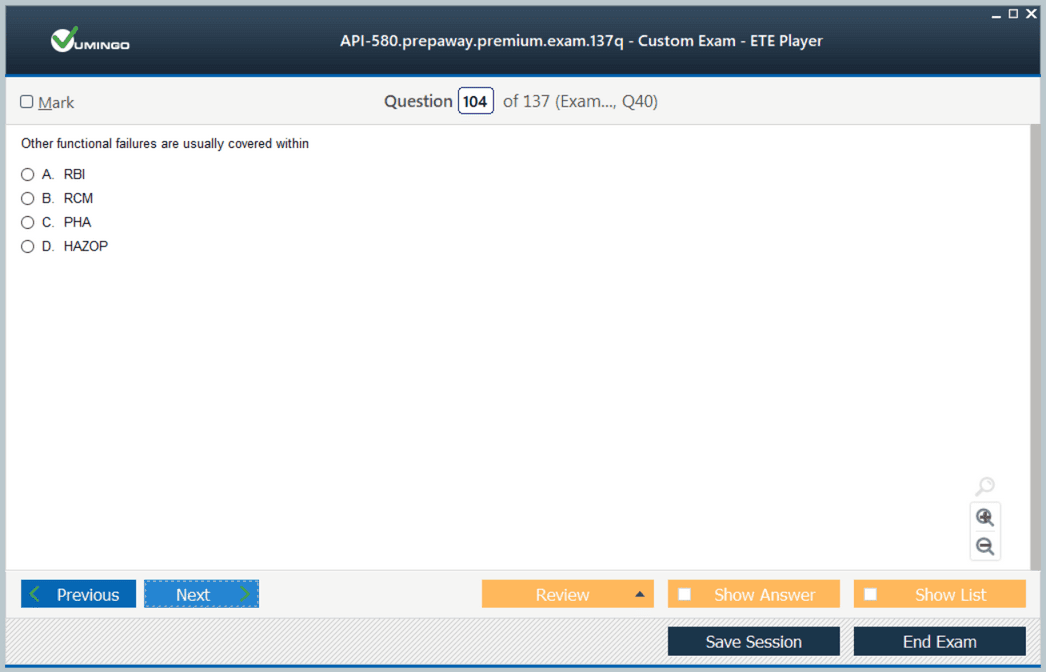

API-580 exam preparation also focuses on integrating risk-based inspection with broader maintenance and reliability programs. Candidates must understand how RBI complements preventive and predictive maintenance strategies, providing a structured approach to prioritizing inspections, optimizing maintenance schedules, and reducing unplanned downtime.

The exam tests the ability to develop comprehensive maintenance plans that incorporate risk assessment results, inspection data, and operational priorities. Candidates are expected to evaluate trade-offs between inspection frequency, resource allocation, and potential consequences, ensuring that maintenance programs enhance equipment reliability while controlling costs. Integration of RBI into overall maintenance strategy is critical for achieving operational efficiency and long-term equipment integrity.

Advanced Data Interpretation and Predictive Analysis

Candidates are required to demonstrate proficiency in advanced data interpretation and predictive analysis techniques. This includes identifying trends in inspection results, correlating operational parameters with equipment degradation, and predicting future risk levels. Understanding how to apply statistical models, historical data, and operational metrics is essential for developing accurate predictions and actionable inspection strategies.

The API-580 exam evaluates the ability to synthesize multiple data streams into a coherent risk profile. Candidates must assess how changing operational conditions, modifications to equipment, or environmental variations influence risk levels and inspection priorities. Mastery of predictive analysis ensures that inspection and maintenance programs remain proactive, minimizing the likelihood of unexpected failures and enhancing overall system reliability.

Managing Risk Limitations and Mitigation

While risk-based inspection provides a structured approach to managing equipment integrity, candidates must understand its limitations. The exam tests knowledge of scenarios where RBI may not fully mitigate risk, such as poor equipment design, installation errors, insufficient personnel expertise, or unaddressed inspection findings. Candidates must be able to recognize these limitations and recommend complementary measures to reduce residual risk.

Mitigation strategies may include engineering modifications, operational adjustments, enhanced monitoring, or targeted maintenance interventions. Understanding the boundaries of RBI ensures that candidates can apply the methodology effectively while addressing factors that fall outside its scope. Scenario-based questions often present complex cases requiring candidates to balance risk, cost, and operational considerations in developing comprehensive solutions.

Professional Application and Long-Term Benefits

Mastery of API-580 principles extends beyond the exam, supporting professional practice in industrial inspection, maintenance, and reliability management. Knowledge of risk-based inspection enables professionals to prioritize critical assets, optimize inspection schedules, reduce equipment failures, and maintain safe operational conditions. Applying RBI principles enhances decision-making, resource allocation, and long-term equipment performance.

Candidates are expected to understand how to communicate risk assessment findings effectively, justify inspection strategies, and integrate RBI results into broader maintenance and operational programs. Long-term application of API-580 knowledge fosters continuous improvement, supports compliance with industry standards, and enhances professional credibility. Understanding these principles ensures that candidates can implement risk-based inspection programs that are practical, data-driven, and aligned with organizational goals.

Exam Preparation Strategies

Effective preparation for the API-580 exam requires a combination of theoretical study, practical application, and scenario-based practice. Candidates should review core topics, including probability and consequence assessment, damage mechanisms, inspection planning, and risk management methodologies. Scenario analysis is particularly important, as the exam evaluates the ability to apply knowledge in realistic industrial contexts.

Structured study schedules, combined with review of historical case studies and operational data, reinforce comprehension and retention. Hands-on experience in inspection planning, team collaboration, and risk assessment exercises enhances understanding of practical challenges. Simulated problem-solving under timed conditions prepares candidates for the analytical and decision-making requirements of the exam. Integrating theoretical knowledge with practical application ensures comprehensive readiness and confidence on exam day.

Advanced Scenario Analysis and Risk Prioritization

One of the most critical skills tested in the API-580 exam is advanced scenario analysis, which requires candidates to interpret complex operational conditions, identify potential failure points, and determine inspection priorities based on risk. Candidates must understand how to evaluate multiple interacting variables, such as temperature, pressure, chemical exposure, flow conditions, and mechanical stresses, to assess the likelihood of equipment failure. Understanding how these factors combine to affect probability of failure is crucial. Consequence of failure is also evaluated by considering operational, safety, environmental, and financial implications.

The exam assesses the ability to categorize risk levels using structured matrices that integrate probability and consequence. Candidates must be able to identify which equipment or systems present the highest risk and justify inspection and maintenance priorities accordingly. Scenario-based questions often present multiple interacting damage mechanisms, requiring candidates to assess the cumulative impact on system integrity and operational safety. Advanced scenario analysis also involves predicting potential cascading effects where the failure of one component may increase the probability of failure in interconnected systems.

Detailed Assessment of Damage Mechanisms

The API-580 exam places significant emphasis on in-depth understanding of damage mechanisms and their identification in operational equipment. Candidates must be able to distinguish between uniform corrosion, localized corrosion, pitting, crevice corrosion, stress corrosion cracking, fatigue, erosion, sulfidation, oxidation, and other mechanisms. Understanding the environmental, chemical, and operational conditions that promote each type of degradation is essential. Candidates are also expected to evaluate how these mechanisms interact, sometimes simultaneously, to accelerate equipment failure.

Exam preparation requires knowledge of metallurgical factors, including material composition, microstructure, heat treatment, and fabrication methods. These factors influence susceptibility to various damage mechanisms. Candidates must be able to determine how operational conditions, such as high temperature, cyclic stresses, or corrosive environments, impact the rate and mode of degradation. Understanding the relationship between observed damage, underlying mechanisms, and predicted failure modes is critical for developing effective inspection strategies.

Probability of Failure Modeling and Analysis

Probability of failure modeling is a central component of the API-580 exam. Candidates must be proficient in evaluating historical data, inspection records, and operational trends to estimate the likelihood of failure for each component. Older equipment generally exhibits higher probability levels, but other factors, such as material selection, operating conditions, and maintenance history, also play a role. Candidates must understand methods for updating probability metrics to reflect ongoing operational changes and equipment modifications.

Analytical skills are tested through scenario-based questions where candidates must interpret complex data sets to determine high-risk components. They must understand statistical approaches, empirical correlations, and historical trend analysis to predict equipment degradation accurately. Candidates are expected to demonstrate the ability to integrate multiple factors, including process conditions, environmental exposure, and material behavior, into comprehensive probability assessments.

Consequence of Failure Evaluation Techniques

The exam also evaluates candidates’ understanding of consequence of failure evaluation techniques. This involves assessing potential outcomes of equipment failure in terms of safety, environmental impact, production loss, and financial consequences. Candidates must be able to classify consequences using qualitative and quantitative measures, ranging from minor operational disruption to catastrophic system failure. Scenario questions may present multiple impact factors, requiring candidates to assess both direct and indirect consequences of equipment failure.

Candidates must understand how to integrate consequence analysis with probability assessments to prioritize inspection and maintenance activities. Evaluating worst-case scenarios, secondary impacts, and potential cascading failures is crucial for comprehensive risk management. The ability to quantify consequences, justify inspection intervals, and propose preventive actions is an essential component of API-580 exam readiness.

Inspection Planning and Methodology

API-580 candidates are expected to develop inspection plans based on risk assessment results. This involves selecting appropriate inspection techniques, determining inspection frequency, and prioritizing high-risk equipment. Candidates must understand non-destructive testing methods, including visual inspection, ultrasonic testing, radiography, eddy current testing, magnetic particle inspection, and advanced techniques applicable to specialized equipment. Knowledge of the limitations, accuracy, and applicability of each method is essential for designing effective inspection programs.

The exam evaluates the ability to integrate inspection results into risk management cycles, ensuring that equipment conditions are continuously monitored and inspection priorities are updated as necessary. Candidates must also demonstrate the ability to coordinate inspection activities with maintenance, operational schedules, and regulatory compliance requirements. Scenario-based questions often require the application of these principles to complex operational environments where multiple systems interact and risk levels vary across components.

Data Management and Analytical Skills

A significant portion of the API-580 exam assesses candidates’ ability to manage and analyze inspection and operational data. Candidates must understand the importance of accurate data collection, validation, storage, and retrieval in supporting risk-based inspection programs. This includes evaluating inspection histories, maintenance logs, design specifications, and operational records. Effective data management ensures that risk assessments are reliable and that inspection strategies are evidence-based.

Analytical skills are tested by requiring candidates to interpret complex datasets, identify trends in equipment degradation, and predict future risk levels. Candidates must also be able to identify gaps or inconsistencies in data and determine the impact on risk assessment outcomes. Mastery of data analysis and interpretation ensures that inspection plans are optimized, risks are accurately evaluated, and maintenance resources are allocated effectively.

Collaborative Risk Management

Risk-based inspection is a collaborative effort, and the exam assesses candidates’ ability to work within multidisciplinary teams. Team members typically include equipment inspectors, corrosion specialists, process engineers, operations personnel, safety officers, risk analysts, and financial advisors. Each member contributes unique expertise to ensure comprehensive risk assessment and effective inspection planning.

Candidates must demonstrate an understanding of team roles, responsibilities, and communication practices. Coordinating input from multiple disciplines allows for a holistic evaluation of equipment risk, integration of operational constraints, and development of practical inspection strategies. Scenario-based questions often test the candidate’s ability to facilitate collaboration, prioritize team recommendations, and reconcile conflicting viewpoints to produce actionable inspection plans.

Advanced Scenario-Based Problem Solving

The API-580 exam heavily emphasizes scenario-based problem solving, which challenges candidates to apply knowledge to realistic operational situations. Candidates may encounter scenarios involving multiple interacting damage mechanisms, complex operational conditions, and varying levels of risk. They are expected to analyze these scenarios, identify critical components, and recommend inspection and maintenance strategies that prioritize safety, operational continuity, and resource efficiency.

Effective scenario analysis requires candidates to deconstruct complex problems, evaluate probability and consequence for each element, and consider the interactions among multiple variables. Candidates must integrate operational data, historical trends, and material characteristics to produce comprehensive risk assessments. Scenario-based practice strengthens analytical reasoning and decision-making skills, preparing candidates to address the multifaceted challenges presented in the exam and real-world industrial environments.

Risk Matrices and Prioritization Techniques

Understanding and applying risk matrices is essential for API-580 candidates. Risk matrices provide a visual representation of the relationship between probability and consequence, categorizing equipment into risk levels that guide inspection and maintenance priorities. Candidates must be able to interpret these matrices, adjust thresholds based on operational context, and allocate resources effectively to mitigate high-risk conditions.

The exam evaluates both quantitative and qualitative approaches to risk assessment. Quantitative methods involve statistical analysis, predictive modeling, and historical trend evaluation, while qualitative approaches rely on expert judgment and operational experience. Candidates are expected to understand the strengths and limitations of each approach, apply them appropriately, and justify decisions based on scenario-specific conditions.

Lifecycle Management and Degradation Prediction

A core component of API-580 knowledge involves understanding the lifecycle of industrial equipment and predicting how degradation evolves over time. Candidates must evaluate how material properties, operating conditions, and environmental factors influence equipment performance and risk throughout its service life. Recognizing early indicators of damage, such as localized corrosion or micro-cracking, allows for timely intervention and preventive maintenance.

Candidates are expected to integrate lifecycle analysis with risk assessment and inspection planning. This includes identifying stages of aging, anticipating potential failure points, and developing inspection strategies that mitigate long-term risk. The exam tests the ability to apply predictive techniques, assess the rate of degradation, and recommend maintenance or replacement actions based on observed and anticipated conditions.

Integration with Maintenance and Reliability Programs

The API-580 exam emphasizes the integration of risk-based inspection with broader maintenance and reliability initiatives. Candidates must understand how RBI complements preventive and predictive maintenance, providing a structured approach to resource allocation, inspection scheduling, and operational risk management. Integrating inspection findings into maintenance planning enhances equipment reliability, reduces unplanned downtime, and optimizes operational efficiency.

Candidates must evaluate trade-offs between inspection frequency, resource allocation, and potential operational impact. Scenario-based questions may require developing comprehensive maintenance strategies that incorporate inspection results, operational priorities, and risk assessments. Mastery of this integration ensures that candidates can implement practical, data-driven programs that maintain equipment integrity while supporting organizational objectives.

Predictive Analysis and Continuous Monitoring

Candidates are expected to demonstrate proficiency in predictive analysis and continuous monitoring techniques. This involves analyzing inspection data, operational parameters, and environmental conditions to forecast equipment performance and anticipate potential failures. Understanding how to apply statistical models, historical data, and trend analysis enables candidates to make informed decisions regarding inspection intervals and maintenance actions.

The exam evaluates the ability to synthesize multiple data sources into actionable risk assessments, identify emerging threats, and adjust inspection plans proactively. Continuous monitoring and predictive analysis allow organizations to address equipment issues before they escalate, ensuring operational safety, reliability, and efficiency. Candidates must also understand how to communicate findings effectively to decision-makers and integrate predictions into long-term maintenance strategies.

Limitations of Risk-Based Inspection

While risk-based inspection provides a structured methodology for equipment integrity management, candidates must understand its limitations. The exam assesses knowledge of factors that can compromise RBI effectiveness, including inaccurate or incomplete data, poor equipment design, improper installation, operational deviations, insufficient team expertise, and failure to act on inspection findings. Candidates must demonstrate awareness of these limitations and propose complementary measures to mitigate residual risk.

Mitigation strategies may include engineering modifications, enhanced monitoring, operational adjustments, or targeted maintenance interventions. Understanding the boundaries of RBI ensures that candidates can apply the methodology effectively while addressing factors outside its scope. Scenario-based questions often challenge candidates to balance risk, cost, and operational constraints in developing comprehensive, practical solutions.

Professional Application and Long-Term Benefits

Mastering API-580 principles provides long-term benefits for professional practice. Effective risk-based inspection enables professionals to prioritize high-risk equipment, reduce failures, optimize maintenance schedules, and maintain safe operations. Applying RBI principles enhances decision-making, resource allocation, and overall system reliability.

Candidates are expected to understand how to communicate risk assessment results, justify inspection strategies, and integrate RBI findings into maintenance and operational programs. Continuous application of API-580 knowledge supports professional growth, operational excellence, and compliance with industry standards. Understanding these principles ensures that candidates can implement sustainable, practical risk-based inspection programs that improve safety and efficiency over the lifecycle of industrial equipment.

Integrating Risk-Based Inspection into Operational Management

A significant aspect of the API-580 exam is understanding how risk-based inspection integrates into broader operational management practices. Candidates must demonstrate knowledge of how inspection results inform maintenance decisions, operational adjustments, and risk mitigation strategies. Risk-based inspection is not an isolated activity but rather a continuous process that interacts with reliability programs, preventive maintenance schedules, and safety management systems. Professionals are expected to understand how to interpret inspection findings, evaluate trends in equipment performance, and make strategic decisions that minimize operational risk while optimizing efficiency.

Candidates are also tested on the ability to align RBI findings with regulatory and industry standards. This includes understanding inspection compliance requirements, documentation protocols, and reporting procedures. Correct integration ensures that inspection results are actionable, traceable, and provide value beyond routine maintenance. The exam assesses the capacity to manage inspection programs in a way that supports operational continuity, ensures safety, and meets both organizational and regulatory expectations.

Advanced Analysis of Damage Acceleration

The API-580 exam emphasizes the ability to analyze how damage mechanisms can accelerate under certain operational or environmental conditions. Candidates must be able to recognize factors that increase the likelihood or speed of equipment degradation, including high-temperature exposure, chemical attack, fluctuating pressures, and cyclic loading. This requires a thorough understanding of material science, equipment design, and the environmental factors that influence corrosion, fatigue, cracking, and other degradation forms.

Candidates are expected to assess how multiple damage mechanisms interact and compound risk. For example, thermal cycling may increase stress corrosion cracking susceptibility, while chemical exposure may accelerate pitting in metals already weakened by mechanical wear. The exam tests the ability to integrate knowledge of material behavior, operational conditions, and environmental factors to predict degradation trends and adjust inspection strategies accordingly.

Evaluating Equipment Reliability

Understanding equipment reliability and its relationship to risk is another key focus of the API-580 exam. Candidates must evaluate how equipment design, material selection, operating conditions, and maintenance practices contribute to system reliability. They are expected to analyze historical failure data, inspection records, and operational logs to determine reliability levels and predict future performance.

The exam also tests candidates on the ability to develop strategies that enhance reliability while minimizing operational disruptions. This includes determining optimal inspection intervals, selecting appropriate inspection methods, and implementing preventive measures to address identified risks. Candidates must integrate reliability assessments with risk-based inspection findings to support decision-making, optimize maintenance budgets, and ensure operational safety.

Risk Communication and Decision Making

Effective risk communication is a critical skill evaluated in the API-580 exam. Candidates must be able to convey complex risk assessments to diverse stakeholders, including operations personnel, management, maintenance teams, and safety officers. Clear communication ensures that inspection findings, risk levels, and recommended actions are understood and implemented effectively.

Decision-making based on risk assessment is another area of focus. Candidates are tested on their ability to prioritize inspection and maintenance activities, balance resource allocation, and justify operational decisions using data-driven analyses. Scenario-based questions often require evaluating multiple options, considering cost, operational impact, safety, and reliability, and selecting the most effective course of action.

Data-Driven Risk Assessment Techniques

The API-580 exam emphasizes data-driven approaches to risk assessment. Candidates must be proficient in using inspection data, operational metrics, and historical performance records to evaluate probability and consequence of failure. Statistical analysis, trend evaluation, and predictive modeling are essential tools for accurate risk assessment.

Candidates are expected to integrate quantitative and qualitative data to create a comprehensive risk profile for each piece of equipment. They must also be able to update risk assessments dynamically based on new data, inspection results, or changes in operational conditions. Scenario-based questions test the ability to apply data-driven methodologies to identify high-risk assets, optimize inspection schedules, and recommend mitigation measures that reduce potential impact.

Prioritization of Inspection Activities

One of the central skills tested in the API-580 exam is the ability to prioritize inspection activities effectively. Candidates must understand how to identify equipment with the highest risk and allocate inspection resources accordingly. Risk matrices, probability of failure calculations, consequence evaluations, and historical data analysis all contribute to establishing inspection priorities.

The exam also assesses candidates on their ability to balance inspection frequency with operational requirements, resource availability, and safety considerations. Scenario-based exercises may present conflicting priorities, requiring candidates to evaluate trade-offs and make informed decisions that maximize risk reduction while minimizing operational disruption. Understanding prioritization principles ensures that inspection programs are efficient, focused on high-risk assets, and capable of preventing unexpected failures.

Monitoring and Continuous Improvement

API-580 emphasizes continuous monitoring of equipment condition and ongoing improvement of inspection programs. Candidates must understand how to implement feedback loops that incorporate inspection findings, operational data, and maintenance actions into future risk assessments. Continuous monitoring allows organizations to adapt inspection plans to changing conditions, evolving damage mechanisms, and new operational challenges.

The exam tests candidates’ ability to recommend process improvements based on monitoring data, identify gaps in inspection coverage, and refine risk assessment methodologies. Understanding the principles of continuous improvement ensures that risk-based inspection programs remain effective, responsive, and aligned with organizational goals over time.

Scenario Integration and Complex Problem Solving

The API-580 exam frequently includes complex scenarios requiring integration of multiple knowledge areas. Candidates must evaluate interactions between damage mechanisms, operational conditions, and environmental factors to develop comprehensive inspection strategies. These scenarios test analytical reasoning, predictive assessment, and the ability to synthesize information from diverse sources.

Candidates are expected to identify primary and secondary failure modes, assess cascading risks, and recommend inspection strategies that address the most critical threats. Scenario integration emphasizes the practical application of knowledge, requiring candidates to move beyond theoretical understanding to develop actionable plans that ensure equipment integrity, safety, and reliability.

Risk Evaluation Under Operational Constraints

Another critical area of API-580 exam preparation involves evaluating risk under operational constraints. Candidates must be able to assess risk when equipment operates under conditions that limit inspection access, resource availability, or operational flexibility. Understanding how to manage risk within these constraints ensures that inspection plans remain practical and achievable without compromising safety.

The exam assesses the ability to make trade-offs between inspection frequency, scope, and operational needs. Candidates must also demonstrate knowledge of mitigation strategies that can reduce risk when ideal inspection conditions are not possible. Effective risk evaluation under constraints ensures operational continuity while maintaining safety and equipment integrity.

Integration of RBI with Safety and Environmental Programs

Candidates must understand the connection between risk-based inspection, safety management, and environmental protection. The API-580 exam evaluates the ability to identify potential safety hazards and environmental impacts associated with equipment failure. Candidates are expected to integrate RBI findings into broader safety and environmental programs, ensuring that risk reduction strategies align with organizational policies and regulatory requirements.

This integration includes evaluating the consequences of equipment failure on personnel safety, environmental compliance, and operational continuity. Candidates must demonstrate the ability to develop inspection plans and preventive measures that reduce both operational and environmental risk, supporting safe and sustainable operations.

Advanced Risk Metrics and Performance Indicators

The API-580 exam assesses candidates’ ability to define and apply advanced risk metrics and performance indicators. Candidates must understand how to quantify risk levels, track inspection effectiveness, and measure improvements in equipment reliability. Metrics may include frequency of inspection, probability of failure trends, consequence of failure impact, and overall risk reduction achieved through inspection and maintenance activities.

Candidates must also demonstrate the ability to use these metrics to guide decision-making, justify resource allocation, and communicate inspection outcomes to management. Understanding how to evaluate performance indicators ensures that RBI programs deliver measurable improvements in safety, reliability, and operational efficiency.

Predictive Maintenance Integration

Risk-based inspection is closely linked to predictive maintenance strategies, and the API-580 exam evaluates candidates’ ability to integrate these approaches. Candidates must understand how predictive maintenance data, such as vibration analysis, temperature monitoring, or corrosion rate measurements, can inform risk-based inspection decisions. This integration allows organizations to anticipate equipment failures, schedule timely inspections, and implement preventive measures that reduce downtime and operational risk.

The exam tests the ability to combine predictive maintenance insights with risk assessment principles to optimize inspection planning, prioritize high-risk assets, and enhance overall equipment performance. Candidates are expected to develop actionable strategies that align predictive data with inspection schedules, operational requirements, and maintenance budgets.

Limitations of Risk-Based Inspection Programs

The API-580 exam evaluates candidates’ understanding of the limitations of risk-based inspection programs. Candidates must recognize that RBI cannot compensate for poor equipment design, improper installation, operational deviations, or human error. Additionally, incomplete data, lack of trained personnel, and failure to implement inspection recommendations can reduce the effectiveness of RBI.

Candidates are expected to propose complementary measures to address these limitations. This may include engineering modifications, enhanced monitoring, operational adjustments, or targeted maintenance interventions. Understanding the scope and boundaries of RBI ensures that candidates can apply the methodology effectively while mitigating residual risks and maintaining operational safety.

Professional Implementation and Long-Term Benefits

Mastering API-580 knowledge provides long-term benefits for professionals in industrial inspection and maintenance. Effective risk-based inspection enables prioritization of high-risk equipment, optimization of maintenance resources, reduction of failures, and enhancement of operational safety. Candidates are expected to understand how to communicate findings, justify inspection strategies, and integrate RBI results into broader operational programs.

Long-term application of API-580 principles supports continuous improvement, compliance with industry standards, and sustainable operational practices. Professionals equipped with these skills are able to implement practical, data-driven inspection programs that enhance reliability, reduce operational risks, and contribute to overall organizational performance.

Exam Preparation and Success Strategies

Preparing for the API-580 exam requires a combination of theoretical study, practical application, and scenario-based exercises. Candidates should familiarize themselves with the standard, understand probability and consequence assessment, and practice interpreting inspection data and operational metrics. Scenario-based practice is particularly important, as the exam tests the ability to apply knowledge in realistic, complex industrial situations.

Structured study plans, hands-on inspection experience, and simulation of real-world scenarios enhance candidate readiness. Understanding the integration of risk assessment with inspection planning, operational management, and maintenance strategy ensures comprehensive preparation. Combining theoretical knowledge, practical application, and analytical reasoning strengthens confidence and performance on the exam.

Comprehensive Risk Evaluation Framework

A critical focus of the API-580 exam is understanding how to develop a comprehensive risk evaluation framework that integrates multiple variables affecting equipment integrity. Candidates must evaluate probability of failure and consequence of failure together to prioritize inspection and maintenance activities effectively. A robust framework considers operational conditions, equipment age, material properties, environmental factors, and historical performance. Candidates are expected to synthesize these elements to identify high-risk components and implement targeted inspection strategies.

The exam tests the ability to construct frameworks that dynamically adapt to evolving conditions. For example, changes in process parameters, modifications in equipment design, or unexpected environmental impacts must be incorporated into risk evaluations. Candidates must also demonstrate the capacity to balance risk reduction with operational efficiency, ensuring that resources are allocated to critical components while maintaining production continuity.

Damage Mechanism Interaction and Complexity

Advanced knowledge of damage mechanism interaction is a key element in API-580 exam preparation. Candidates must understand that equipment degradation is rarely caused by a single factor. Multiple mechanisms, such as corrosion, cracking, thermal fatigue, and erosion, often interact and accelerate failure. Recognizing these interactions enables candidates to predict potential failure points more accurately and design inspection strategies that target areas of compounded risk.

Candidates are expected to differentiate between primary and secondary mechanisms and understand how one form of degradation may trigger or exacerbate another. The exam evaluates the ability to assess complex scenarios where multiple damage mechanisms act simultaneously, requiring an integrated analysis approach. Understanding these interactions also supports decisions regarding repair methods, inspection frequency, and mitigation strategies.

Probability and Consequence Modeling Techniques

A central aspect of the API-580 exam is the ability to model probability and consequence of failure accurately. Candidates must apply both quantitative and qualitative techniques, integrating statistical analysis, historical data, material performance metrics, and operational conditions. Probability modeling requires understanding failure trends, lifecycle stages, and environmental impacts on equipment degradation. Consequence modeling involves assessing potential safety hazards, financial implications, environmental impacts, and operational disruption.

The exam evaluates the ability to use risk matrices, predictive models, and scenario simulations to categorize equipment according to risk levels. Candidates must also understand how to interpret modeling results and adjust inspection plans accordingly. Effective modeling supports prioritization, ensures targeted inspection, and maximizes resource efficiency while maintaining operational safety.

Inspection Strategy Design and Optimization

Candidates must demonstrate proficiency in designing inspection strategies based on risk assessment outcomes. API-580 exam questions test the ability to select appropriate inspection techniques, define inspection intervals, and prioritize high-risk assets. Knowledge of non-destructive testing methods, including ultrasonic, radiographic, magnetic particle, and eddy current inspections, is essential. Candidates must understand the limitations, advantages, and applicability of each technique to different materials and damage mechanisms.

The exam also evaluates the ability to optimize inspection strategies by balancing risk reduction, operational constraints, and available resources. Scenario-based exercises often require candidates to develop inspection plans that are practical, efficient, and capable of detecting potential failures before they escalate. Optimization includes determining the most effective inspection type, frequency, and coverage for each component, ensuring comprehensive risk management.

Data Integration and Analysis

Effective risk-based inspection relies on the collection, integration, and analysis of comprehensive data sets. Candidates are tested on their ability to gather information from design documents, maintenance logs, inspection reports, operational records, and environmental monitoring systems. Proper data integration enables accurate risk assessment, trend analysis, and predictive modeling.

Candidates must demonstrate the ability to identify gaps in data, validate information, and interpret results to support inspection planning. The exam evaluates how candidates use data to monitor equipment performance over time, predict failure probability, and determine appropriate inspection intervals. Strong data management and analytical skills ensure that risk-based inspection programs are evidence-driven and reliable.

Team Collaboration and Multidisciplinary Integration

API-580 emphasizes the importance of collaboration among multidisciplinary teams. Candidates must understand the roles of inspectors, corrosion specialists, process engineers, operations personnel, safety officers, risk analysts, and financial experts in developing and implementing effective inspection programs. The exam evaluates the ability to facilitate communication, coordinate responsibilities, and integrate input from multiple disciplines into comprehensive risk assessments.

Candidates are expected to demonstrate skills in leading or participating in team-based risk evaluations, ensuring that diverse perspectives inform inspection priorities. Scenario-based questions often involve coordinating teams under operational constraints, requiring candidates to reconcile conflicting viewpoints and arrive at actionable solutions. Effective collaboration ensures that inspection strategies are well-rounded, practical, and aligned with organizational objectives.

Scenario-Based Risk Assessment

The API-580 exam heavily tests the ability to conduct scenario-based risk assessments. Candidates are presented with complex operational situations involving interacting damage mechanisms, variable operational conditions, and multiple equipment types. They must analyze these scenarios to identify high-risk components, assess potential consequences, and recommend inspection strategies that mitigate risk effectively.

Scenario-based assessment requires a systematic approach: identifying potential failure modes, evaluating interactions, determining probability and consequence, and integrating findings into inspection plans. Candidates must demonstrate critical thinking, analytical reasoning, and the ability to apply theoretical knowledge to practical challenges. Scenario analysis ensures that candidates are prepared for real-world situations and capable of developing actionable inspection programs.

Risk Prioritization and Resource Allocation

An essential component of the API-580 exam is the prioritization of risk and allocation of inspection resources. Candidates must understand how to rank equipment based on risk levels, considering both probability and consequence of failure. Risk matrices, historical data analysis, and predictive modeling are used to determine which assets require the most immediate attention.

Candidates are expected to allocate resources effectively, balancing inspection needs with operational demands and budgetary constraints. The exam evaluates the ability to justify inspection priorities, optimize coverage, and ensure that high-risk equipment is monitored adequately. Effective prioritization enhances operational safety, reduces unplanned downtime, and supports efficient maintenance planning.

Continuous Monitoring and Feedback Loops

The API-580 exam emphasizes the importance of continuous monitoring and feedback loops in risk-based inspection programs. Candidates must understand how to use inspection findings, operational data, and predictive metrics to update risk assessments continuously. Feedback loops ensure that inspection strategies evolve with changing conditions, improving the accuracy of risk predictions and the effectiveness of preventive measures.

Candidates are expected to demonstrate the ability to implement monitoring programs, interpret evolving data, and adjust inspection plans dynamically. Scenario-based questions test the ability to respond to emerging risks, integrate new information into existing programs, and maintain operational continuity while reducing potential failures. Continuous monitoring and feedback ensure that RBI programs remain proactive, adaptive, and aligned with organizational goals.

Predictive Analysis and Equipment Performance Forecasting

Predictive analysis is a crucial element of the API-580 exam. Candidates must be able to forecast equipment performance using inspection data, operational metrics, and environmental factors. Understanding how to predict potential failures allows for proactive inspection scheduling, targeted maintenance, and reduced operational risk.

The exam evaluates the ability to interpret trends, model degradation progression, and recommend inspection intervals based on predictive insights. Candidates must also demonstrate knowledge of how to integrate predictive data into risk assessments and inspection strategies, ensuring that high-risk components are identified and maintained before failure occurs. Predictive analysis enhances operational reliability and supports data-driven decision-making.

Limitations and Risk Mitigation

Candidates must understand the limitations of risk-based inspection programs. The API-580 exam assesses awareness of factors that can reduce RBI effectiveness, including incomplete or inaccurate data, insufficient personnel expertise, operational deviations, poor equipment design, and failure to implement recommendations. Candidates are expected to propose complementary risk mitigation measures, such as engineering modifications, enhanced monitoring, operational adjustments, or targeted maintenance.

Understanding these limitations ensures that candidates can apply RBI effectively while accounting for residual risk. Scenario-based questions often present challenging conditions, requiring candidates to balance operational constraints, resource availability, and risk reduction strategies to achieve practical outcomes. Awareness of limitations is essential for developing robust inspection programs that maintain safety and reliability.

Integration with Maintenance and Reliability Programs

API-580 exam candidates must demonstrate the ability to integrate risk-based inspection with overall maintenance and reliability strategies. This includes coordinating inspection results with preventive maintenance, predictive monitoring, and operational scheduling. Proper integration ensures that inspection findings inform maintenance decisions, optimize resource allocation, and enhance equipment reliability.

Candidates are expected to evaluate trade-offs between inspection frequency, maintenance schedules, and operational constraints. Scenario questions may involve designing integrated programs that combine risk assessment, predictive analysis, and operational priorities to maintain equipment integrity. Successful integration supports efficient operations, reduces failures, and ensures compliance with industry standards.

Performance Metrics and Evaluation

The API-580 exam evaluates candidates’ ability to define, measure, and interpret performance metrics in the context of risk-based inspection. Metrics such as failure frequency, inspection coverage, probability of failure trends, and overall risk reduction are used to assess the effectiveness of inspection programs. Candidates must understand how to apply these metrics to justify inspection strategies, allocate resources, and communicate results to management.

Scenario-based questions test the ability to evaluate program performance, identify areas for improvement, and implement changes to enhance effectiveness. Metrics and performance evaluation ensure that inspection programs deliver measurable improvements in safety, reliability, and operational efficiency.

Professional Application and Long-Term Value

Mastering API-580 knowledge provides long-term professional benefits. Candidates must understand how to apply risk-based inspection principles to real-world industrial operations, prioritize high-risk equipment, and optimize inspection and maintenance programs. Effective application enhances safety, reliability, operational efficiency, and compliance with industry standards.

Candidates are expected to demonstrate the ability to communicate risk assessments, justify inspection plans, and integrate RBI findings into operational and maintenance programs. Continuous application of these principles supports professional growth, operational excellence, and sustainable asset management. Knowledge of API-580 enables professionals to implement proactive, data-driven inspection programs that maintain long-term equipment integrity and organizational performance.

Exam Preparation Strategies and Practice

Preparation for the API-580 exam requires comprehensive study, practical application, and scenario-based practice. Candidates should focus on probability and consequence analysis, damage mechanism identification, inspection planning, data analysis, predictive assessment, and risk prioritization. Scenario-based exercises are particularly valuable for applying theoretical knowledge to realistic operational challenges.

Candidates should combine structured study plans, review of historical data, and practical inspection exercises to reinforce understanding. Practicing scenario analysis under timed conditions strengthens decision-making, analytical reasoning, and problem-solving skills. Integration of theoretical knowledge with hands-on application ensures readiness for the exam and builds confidence in applying API-580 principles in professional practice.

Conclusion

The API-580 exam represents a comprehensive evaluation of a professional’s ability to apply risk-based inspection principles in industrial settings. Mastery of the exam requires a deep understanding of probability of failure, consequence of failure, damage mechanisms, inspection planning, and predictive maintenance. Candidates must be able to integrate data from multiple sources, assess operational conditions, and prioritize high-risk equipment to ensure safety, reliability, and operational efficiency.

Preparation for the exam emphasizes scenario-based analysis, multidisciplinary collaboration, and the ability to synthesize complex information into actionable inspection strategies. Candidates are expected to evaluate interacting damage mechanisms, forecast degradation trends, and apply predictive analytics to optimize inspection schedules. Understanding the limitations of risk-based inspection and proposing complementary mitigation measures is also essential for practical implementation.

Successfully passing the API-580 exam demonstrates proficiency in structured risk assessment, strategic inspection planning, and operational decision-making. Professionals equipped with this knowledge can improve equipment reliability, reduce failures, enhance safety, and allocate resources efficiently. Beyond exam success, the principles of API-580 provide long-term value by supporting continuous improvement, compliance with industry standards, and sustainable management of industrial assets.

The exam challenges candidates to think critically, integrate technical knowledge with operational insights, and apply engineering judgment in dynamic scenarios. It reinforces the importance of evidence-based decision-making, proactive monitoring, and interdisciplinary collaboration. For professionals in inspection, maintenance, and operational management roles, API-580 serves as a benchmark for expertise, ensuring that they can implement effective risk-based inspection programs that protect people, assets, and the environment.

Mastery of the API-580 standard is not just about passing the exam; it is about developing the skills and judgment necessary to make informed, strategic decisions in complex industrial environments. By combining analytical rigor, practical application, and continuous learning, certified professionals contribute to safer, more reliable, and more efficient operations. API-580 knowledge empowers individuals to prioritize inspections, mitigate risks, and implement proactive maintenance strategies that deliver measurable benefits to organizations and the industries they serve.

API API-580 practice test questions and answers, training course, study guide are uploaded in ETE Files format by real users. Study and Pass API-580 Risk Based Inspection certification exam dumps & practice test questions and answers are to help students.

Exam Comments * The most recent comment are on top

Why customers love us?

What do our customers say?

The resources provided for the API certification exam were exceptional. The exam dumps and video courses offered clear and concise explanations of each topic. I felt thoroughly prepared for the API-580 test and passed with ease.

Studying for the API certification exam was a breeze with the comprehensive materials from this site. The detailed study guides and accurate exam dumps helped me understand every concept. I aced the API-580 exam on my first try!

I was impressed with the quality of the API-580 preparation materials for the API certification exam. The video courses were engaging, and the study guides covered all the essential topics. These resources made a significant difference in my study routine and overall performance. I went into the exam feeling confident and well-prepared.

The API-580 materials for the API certification exam were invaluable. They provided detailed, concise explanations for each topic, helping me grasp the entire syllabus. After studying with these resources, I was able to tackle the final test questions confidently and successfully.

Thanks to the comprehensive study guides and video courses, I aced the API-580 exam. The exam dumps were spot on and helped me understand the types of questions to expect. The certification exam was much less intimidating thanks to their excellent prep materials. So, I highly recommend their services for anyone preparing for this certification exam.

Achieving my API certification was a seamless experience. The detailed study guide and practice questions ensured I was fully prepared for API-580. The customer support was responsive and helpful throughout my journey. Highly recommend their services for anyone preparing for their certification test.

I couldn't be happier with my certification results! The study materials were comprehensive and easy to understand, making my preparation for the API-580 stress-free. Using these resources, I was able to pass my exam on the first attempt. They are a must-have for anyone serious about advancing their career.

The practice exams were incredibly helpful in familiarizing me with the actual test format. I felt confident and well-prepared going into my API-580 certification exam. The support and guidance provided were top-notch. I couldn't have obtained my API certification without these amazing tools!

The materials provided for the API-580 were comprehensive and very well-structured. The practice tests were particularly useful in building my confidence and understanding the exam format. After using these materials, I felt well-prepared and was able to solve all the questions on the final test with ease. Passing the certification exam was a huge relief! I feel much more competent in my role. Thank you!

The certification prep was excellent. The content was up-to-date and aligned perfectly with the exam requirements. I appreciated the clear explanations and real-world examples that made complex topics easier to grasp. I passed API-580 successfully. It was a game-changer for my career in IT!