Pass Six Sigma Lean Six Sigma Certification Exams in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

Lean Six Sigma Premium Bundle

- LSSBB Exam

- LSSGB Exam

- LSSMBB Exam 1 product

- LSSWB Exam

- LSSYB Exam

LSSBB Premium Bundle

- Premium File 300 Questions & Answers

Last update: Feb 11, 2026 - Training Course 45 Video Lectures

Purchase Individually

Premium File

Training Course

LSSGB Premium Bundle

- Premium File 162 Questions & Answers

Last update: Feb 11, 2026 - Training Course 212 Video Lectures

- Study Guide 664 Pages

Purchase Individually

Premium File

Training Course

Study Guide

LSSMBB Premium Bundle

Purchase Individually

Premium File

LSSWB Premium Bundle

- Premium File 171 Questions & Answers

Last update: Feb 11, 2026 - Training Course 53 Video Lectures

Purchase Individually

Premium File

Training Course

LSSYB Premium Bundle

- Premium File 150 Questions & Answers

Last update: Feb 04, 2026 - Training Course 84 Video Lectures

- Study Guide 382 Pages

Purchase Individually

Premium File

Training Course

Study Guide

LSSBB Exam - Lean Six Sigma Black Belt

LSSBB Premium Bundle

- Premium File 300 Questions & Answers. Last update: Feb 11, 2026

- Training Course 45 Video Lectures

| Download Free LSSBB Exam Questions |

|---|

LSSGB Exam - Lean Six Sigma Green Belt

LSSGB Premium Bundle

- Premium File 162 Questions & Answers. Last update: Feb 11, 2026

- Training Course 212 Video Lectures

- Study Guide Pages

| Download Free LSSGB Exam Questions |

|---|

LSSMBB Exam - Lean Six Sigma Master Black Belt

LSSMBB Premium ETE File

- Premium File 400 Questions & Answers

Whats Included:

- Latest Questions

- 100% Accurate Answers

- Fast Exam Updates

| Download Free LSSMBB Exam Questions |

|---|

LSSWB Exam - Lean Six Sigma White Belt

LSSWB Premium Bundle

- Premium File 171 Questions & Answers. Last update: Feb 11, 2026

- Training Course 53 Video Lectures

| Download Free LSSWB Exam Questions |

|---|

LSSYB Exam - Lean Six Sigma Yellow Belt

LSSYB Premium Bundle

- Premium File 150 Questions & Answers. Last update: Feb 04, 2026

- Training Course 84 Video Lectures

- Study Guide Pages

| Download Free LSSYB Exam Questions |

|---|

Six Sigma Lean Six Sigma Certification Practice Test Questions and Answers, Six Sigma Lean Six Sigma Certification Exam Dumps

All Six Sigma Lean Six Sigma certification exam dumps, study guide, training courses are prepared by industry experts. Six Sigma Lean Six Sigma certification practice test questions and answers, exam dumps, study guide and training courses help candidates to study and pass hassle-free!

The Foundation of Operational Excellence in Lean Six Sigma

Lean Six Sigma is a potent methodology that merges two distinct but complementary process improvement frameworks: Lean and Six Sigma. To fully appreciate its benefits, one must first understand its constituent parts. Lean originated from the Toyota Production System and is relentlessly focused on maximizing value for the customer while minimizing waste. It identifies specific types of waste, such as defects, overproduction, waiting, and unused talent, and provides tools to systematically eliminate them. The core principle of Lean is to create a smooth, efficient flow of value to the customer.

Six Sigma, on the other hand, is a data-driven methodology developed by Motorola. Its primary objective is to reduce process variation and eliminate defects. It achieves this through a structured problem-solving approach and the rigorous use of statistical tools. The term "Six Sigma" itself refers to a statistical level of quality, aiming for fewer than 3.4 defects per million opportunities. When combined, Lean's focus on speed and waste removal complements Six Sigma's focus on quality and effectiveness, creating a holistic system for achieving operational excellence that is greater than the sum of its parts.

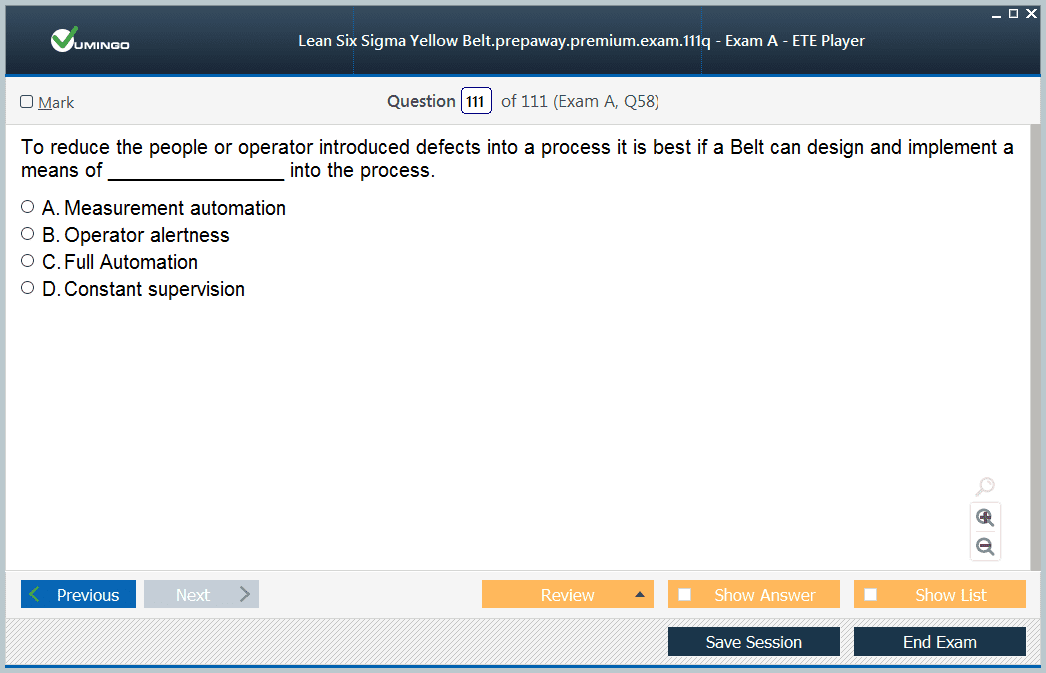

The Core Principle: Error Elimination

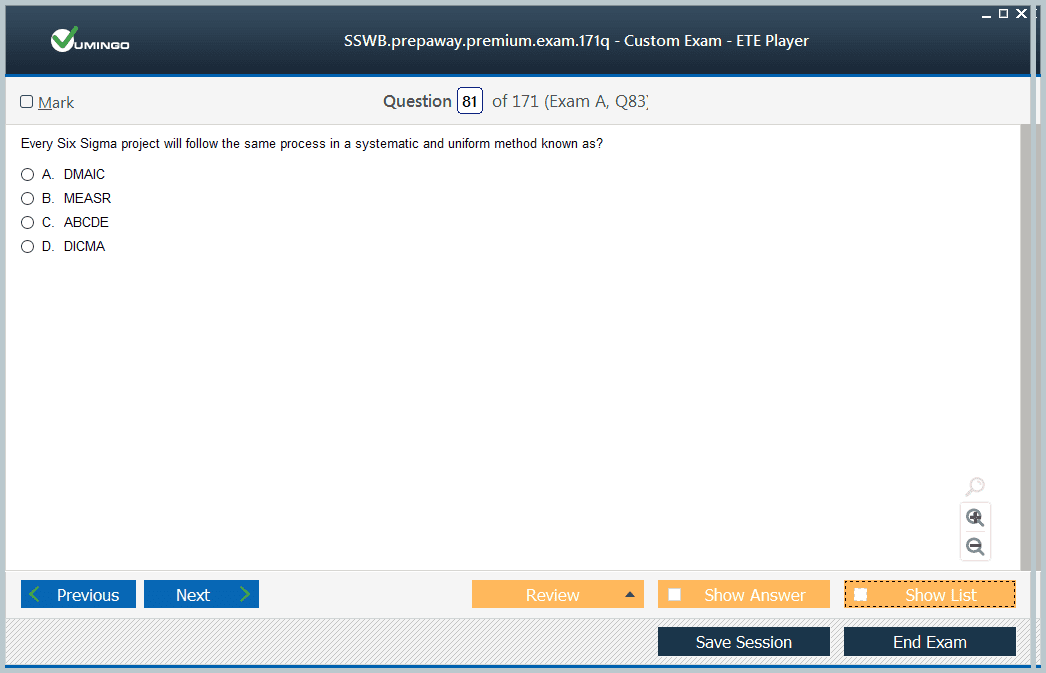

One of the most immediate and impactful benefits of implementing Lean Six Sigma is its systematic approach to error elimination. Errors, or defects, are a significant source of financial loss, customer dissatisfaction, and operational inefficiency. The Six Sigma component of the methodology provides a robust framework known as DMAIC (Define, Measure, Analyze, Improve, Control) to tackle these issues head-on. This structured process ensures that problems are not just superficially fixed but are permanently resolved by addressing their underlying root causes, preventing their recurrence.

In the Define phase, the problem is clearly articulated. The Measure phase involves collecting data to quantify the current performance and the extent of the problem. During the Analyze phase, teams use statistical tools to identify the root causes of the errors. This data-driven analysis is crucial, as it moves the team beyond assumptions and towards factual evidence. The Improve phase is where solutions are developed and implemented to address these root causes. Finally, the Control phase establishes mechanisms to ensure the improvements are sustained over the long term, locking in the gains and preventing a regression to old habits.

Unlocking Efficiency Through Waste Reduction

While Six Sigma zeroes in on defects, the Lean aspect of the methodology is dedicated to the relentless pursuit and elimination of waste. In the Lean philosophy, waste is defined as any activity that consumes resources but does not add value from the customer's perspective. There are eight commonly recognized types of waste, often remembered by the acronym DOWNTIME: Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing. Each of these represents an opportunity for improvement and cost savings within an organization.

Lean Six Sigma provides a toolkit of techniques to identify and eradicate these forms of waste. Value Stream Mapping (VSM) is a fundamental tool used to visualize the entire process flow, from raw materials to the final customer. This visualization makes it easy to spot non-value-adding steps, bottlenecks, and delays. Other tools, such as 5S (Sort, Set in Order, Shine, Standardize, Sustain), help create an organized and efficient workplace, reducing wasted motion and time spent searching for tools or information. By systematically targeting and removing waste, organizations can dramatically improve their efficiency.

Accelerating Progress: Reduction in Project Lifecycle Time

A direct consequence of eliminating waste and streamlining processes is a significant reduction in project and product lifecycle times. In today's fast-paced market, the ability to bring new products or services to market quickly is a major competitive advantage. Lean Six Sigma achieves this by tackling the root causes of delays. Techniques like Value Stream Mapping identify bottlenecks where work piles up, and Kaizen events, which are short-burst improvement workshops, empower teams to rapidly implement changes that improve flow and reduce waiting times.

This reduction in cycle time is not just about working faster; it is about working smarter. By removing unnecessary steps, automating tasks where appropriate, and ensuring a smooth handoff between different stages of a process, the overall time from concept to delivery is shortened. This not only allows the organization to be more responsive to customer needs but also reduces the costs associated with long projects, such as tied-up capital and labor. Faster turnarounds lead to quicker revenue generation and a more agile organization capable of adapting to market shifts.

The DMAIC Framework in Action

The DMAIC framework is the backbone of Six Sigma projects and is fundamental to realizing many of its benefits. Let's consider a practical example of its application. Imagine a software development company experiencing frequent bugs in its final product releases, leading to customer complaints and costly patches. Using DMAIC, a project team would first define the problem specifically, such as "reduce critical bugs reported by customers in the first 30 days post-launch by 50%." This creates a clear, measurable goal for the project.

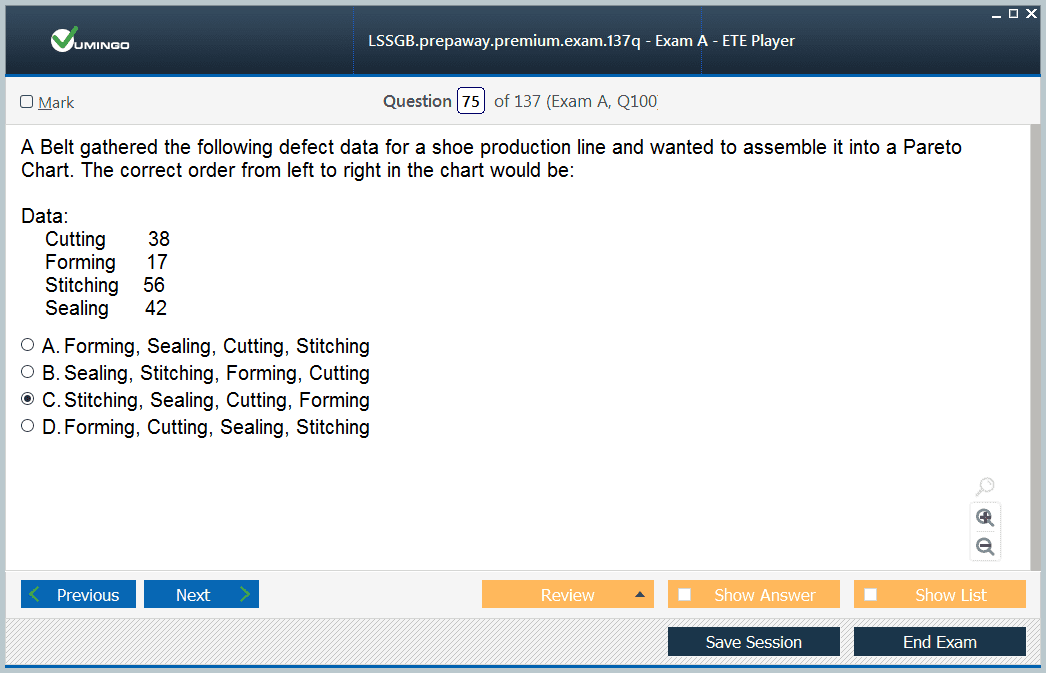

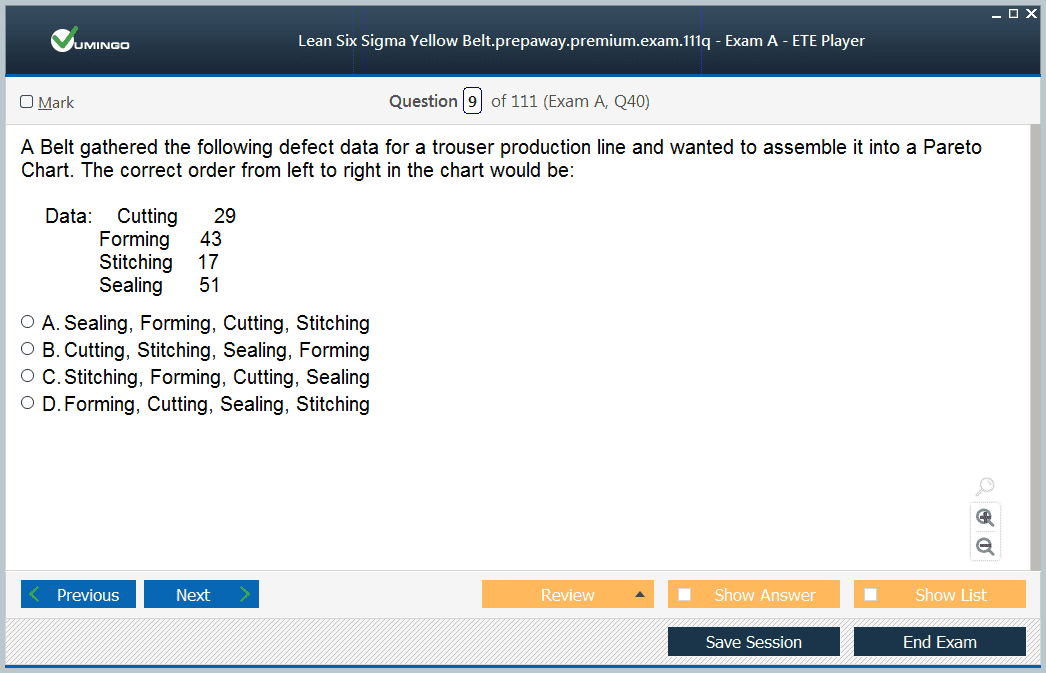

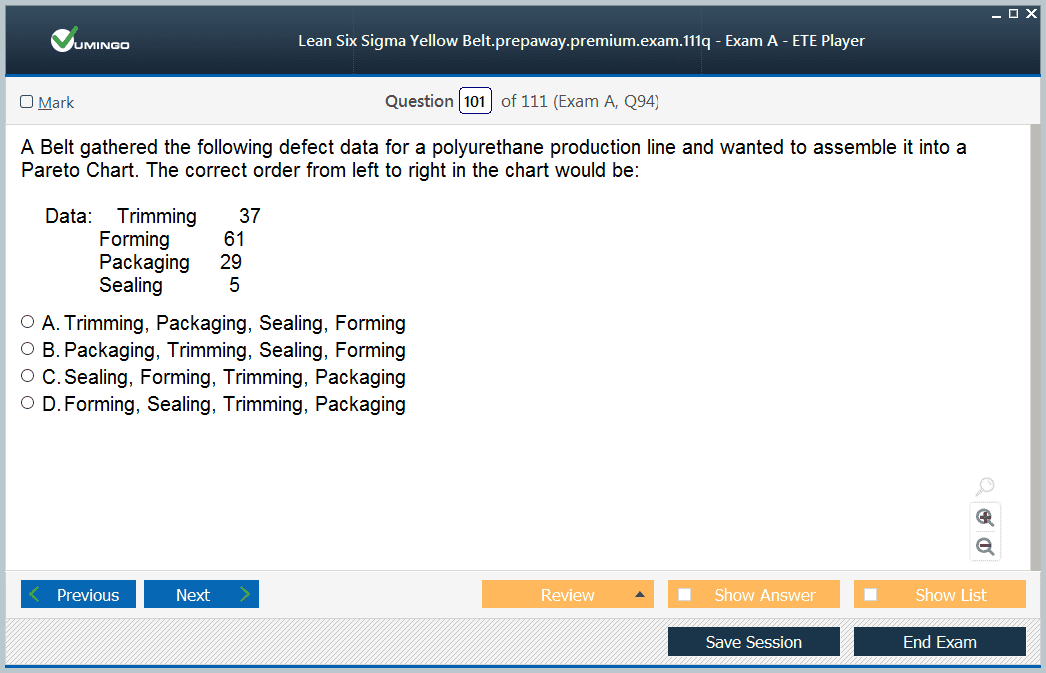

Next, the team would measure the current process, collecting data on the number and types of bugs, where they originate in the development cycle, and the time taken to fix them. In the Analyze phase, they might use tools like a Fishbone Diagram or Pareto Charts to identify the most likely root causes, suchas inadequate code reviews, insufficient automated testing, or unclear user requirements. Based on this analysis, they would implement improvements, like a mandatory peer-review checklist or expanded test coverage. Finally, in the Control phase, they would monitor the bug rate and update their development standards to ensure the new processes are followed consistently.

Visual Management and the 5S System

A key tenet of Lean is making processes transparent and easy to understand. This is often achieved through visual management, where critical information about the process is displayed clearly in the workspace. The 5S system is a foundational practice for creating this visual and organized environment. The first step, Sort, involves removing all unnecessary items from the workspace. Set in Order is the process of organizing the remaining items logically, so everything has a designated place. Shine involves cleaning the workspace, which often helps in identifying potential issues like leaks or loose parts.

The final two steps, Standardize and Sustain, are crucial for long-term success. Standardize involves creating a consistent set of rules and procedures for maintaining the first three S's. This could include creating checklists or using visual cues like color-coding and outlines to show where tools belong. Sustain is the most challenging step; it involves instilling the discipline to maintain these standards over time through regular audits and communication. A well-implemented 5S program dramatically reduces waste related to searching and motion, improves safety, and boosts employee morale by creating a more pleasant work environment.

Value Stream Mapping for Process Visibility

Value Stream Mapping (VSM) is an indispensable Lean tool for understanding and improving the flow of materials and information. It provides a holistic view of a process, helping teams to see the "big picture" rather than just isolated steps. The process begins with creating a "current state" map that documents every step involved in delivering a product or service to the customer. This map includes crucial data points for each step, such as cycle time, changeover time, and the number of operators involved.

Crucially, the VSM distinguishes between value-adding activities and non-value-adding activities. This visual distinction is incredibly powerful, as it often reveals a surprising amount of waste and delay in the system. Once the current state is understood, the team collaborates to design a "future state" map. This map represents an improved process with much of the identified waste eliminated. The future state map then becomes the blueprint for the improvement plan, guiding the implementation of specific Kaizen events or projects to achieve the desired state of efficiency and flow.

Driving Profitability Through Cost-Cutting Measures

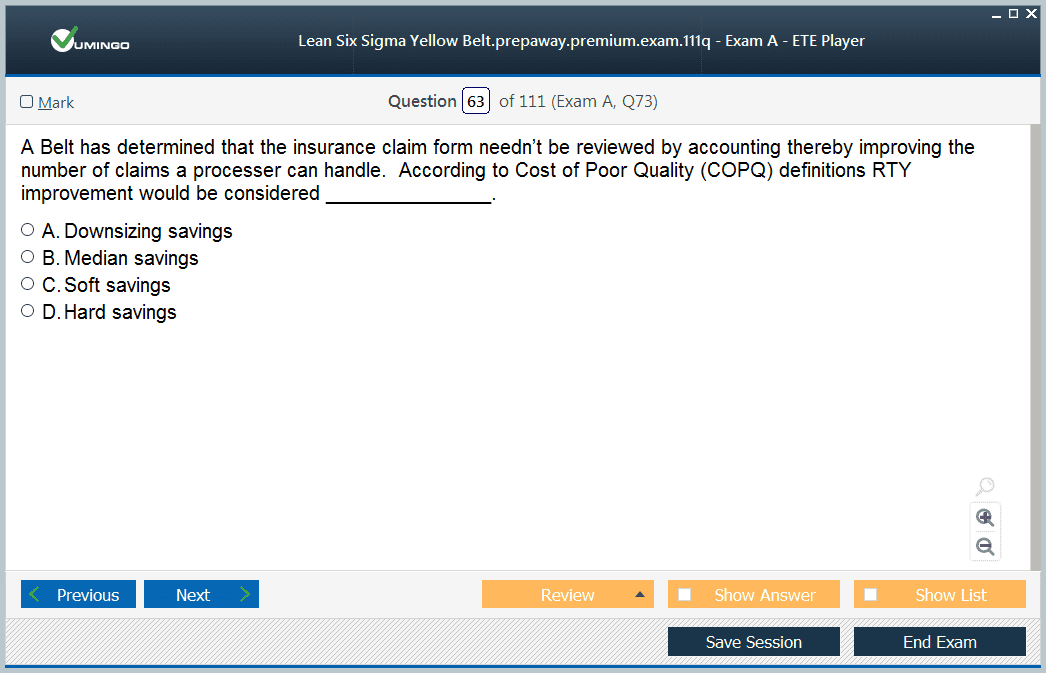

One of the most compelling reasons for businesses to adopt Lean Six Sigma is its proven ability to deliver significant cost savings. These savings are not achieved through arbitrary budget cuts but through the systematic elimination of inefficiencies. A primary source of these savings comes from reducing the Cost of Poor Quality (COPQ). This includes all the expenses incurred due to defects and errors, such as rework, scrap materials, warranty claims, and the labor required to handle customer complaints. By using Six Sigma tools to reduce defects, these costs are drastically minimized.

Lean principles contribute to cost reduction by targeting the eight wastes. For example, reducing overproduction and excess inventory frees up working capital and lowers storage and handling costs. Optimizing transportation routes and workplace layouts reduces fuel and labor expenses. By making processes more efficient, organizations can often increase their output without needing to invest in additional equipment or personnel. These tangible financial benefits directly improve the bottom line, making the business more profitable and resilient.

Enhancing Strategic Planning and Execution

Lean Six Sigma is more than just a set of tools for solving operational problems; it is a framework that can be integrated into the very core of an organization's strategic planning process. It provides a data-driven approach that helps leaders make more informed decisions. By understanding the current capabilities and limitations of their processes, executives can set more realistic and achievable strategic goals. This alignment ensures that improvement projects are not random but are directly linked to the overarching objectives of the business.

A powerful tool for this integration is Hoshin Kanri, also known as Policy Deployment. This method helps cascade strategic goals from the executive level down to the front-line teams. It ensures that every improvement project, or Kaizen event, is clearly tied to a specific strategic objective. This creates a clear line of sight for all employees, helping them understand how their daily work contributes to the company's success. This strategic alignment focuses the organization's resources on the initiatives that will have the greatest impact, maximizing the return on improvement efforts.

Fortifying the Business with Enhanced Risk Management

In today's volatile business environment, effective risk management is crucial for long-term survival and success. Lean Six Sigma provides a structured and proactive approach to identifying, assessing, and mitigating risks within business processes. A key tool used for this purpose is the Failure Mode and Effects Analysis (FMEA). FMEA is a systematic technique that prompts teams to brainstorm potential failure modes in a process, consider the potential effects of those failures, and identify their root causes. This allows for a comprehensive understanding of what could go wrong.

Once potential failures are identified, the FMEA process involves scoring each one based on its severity, likelihood of occurrence, and the ability to detect it. This results in a Risk Priority Number (RPN), which helps teams prioritize which risks to address first. By focusing on the highest-priority risks, organizations can proactively implement countermeasures and control plans to prevent failures from ever occurring. This proactive stance on risk management helps prevent costly disruptions, improves safety, and ensures greater business continuity and stability.

Becoming a Magnet for Business Partners

An organization's reputation for quality and efficiency is a significant asset in the marketplace. Companies that have successfully embedded Lean Six Sigma into their culture often become highly attractive to potential business partners, suppliers, and customers. A commitment to this methodology signals a dedication to operational excellence, reliability, and continuous improvement. Partners know that a Lean Six Sigma organization is likely to have stable, predictable processes, which translates to fewer supply chain disruptions, consistent product quality, and reliable delivery times.

This reputation can lead to significant competitive advantages. It can open doors to strategic alliances and collaborations with other high-performing organizations. Customers are more likely to choose and remain loyal to a company that consistently delivers high-quality products and services on time. Furthermore, in some industries, having a certified quality management system is a prerequisite for doing business. A strong Lean Six Sigma program provides the foundation for achieving and maintaining such certifications, further enhancing the company's market position and appeal to valuable partners.

Understanding the Cost of Poor Quality (COPQ)

To fully grasp the financial benefits of Lean Six Sigma, it is essential to understand the concept of the Cost of Poor Quality (COPQ). COPQ is often referred to as the "hidden factory," representing all the work and costs generated as a result of not doing things right the first time. These costs can be broken down into four main categories. The first two are internal failure costs, which include scrap, rework, and re-testing, and external failure costs, which arise after a product reaches the customer, such as warranty claims, product returns, and complaint handling.

The other two categories are appraisal costs, which are the expenses associated with inspecting and testing products to ensure quality, and prevention costs, which are the investments made to prevent defects from occurring in the first place, such as training and process improvement initiatives. A key goal of Lean Six Sigma is to shift the investment from failure and appraisal costs to prevention costs. While it requires an upfront investment, preventing defects is always far less expensive than finding and fixing them later, leading to substantial long-term savings.

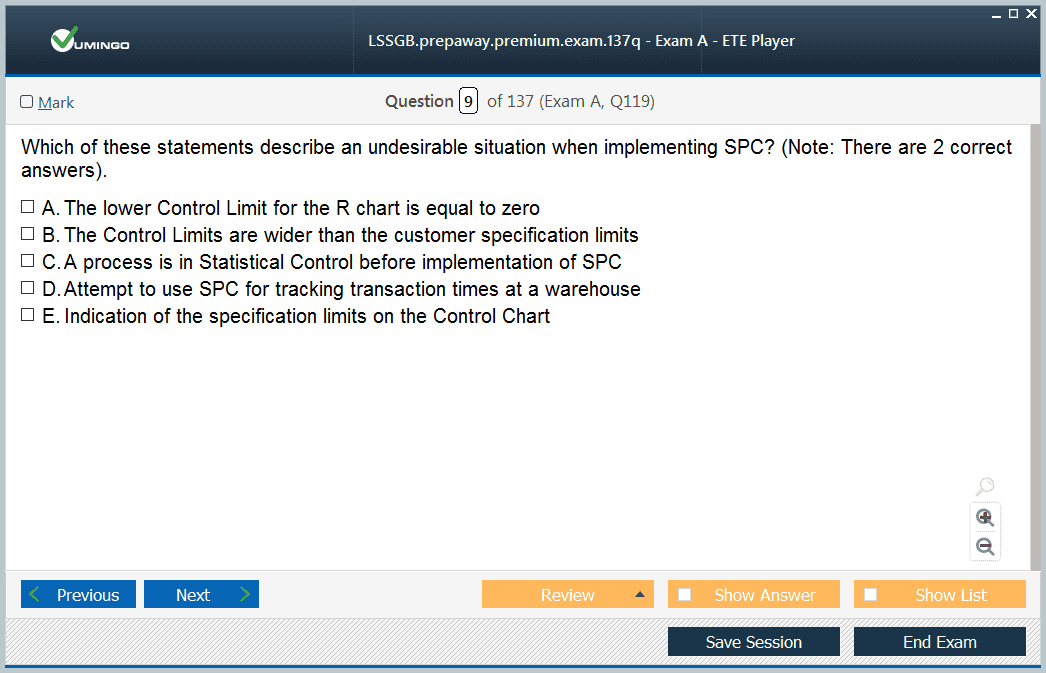

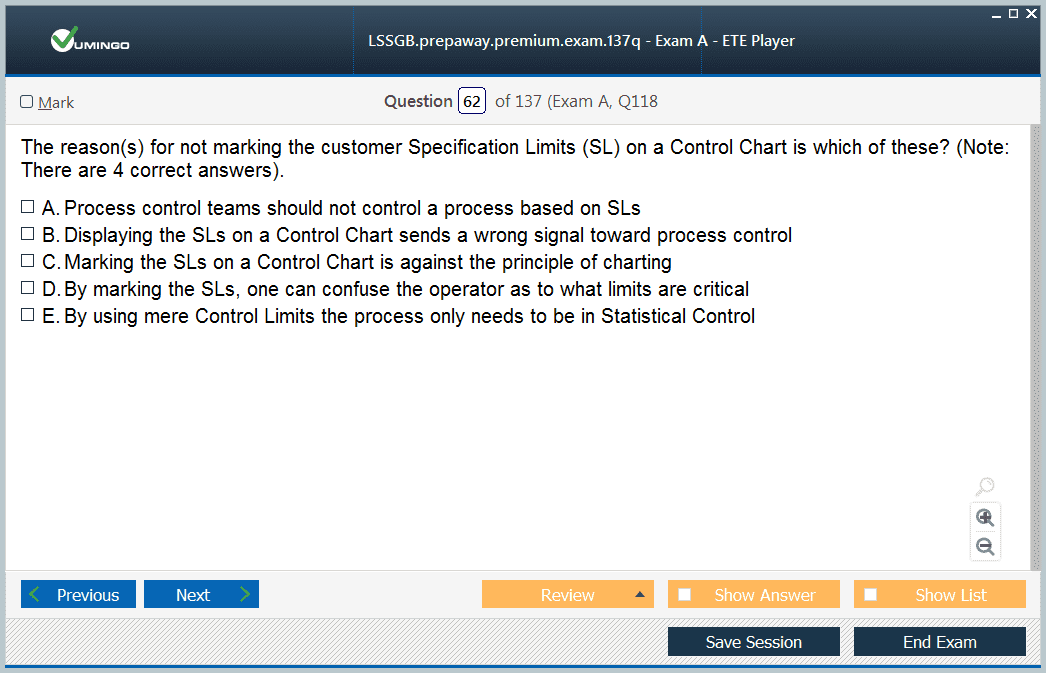

The Role of Statistical Process Control (SPC)

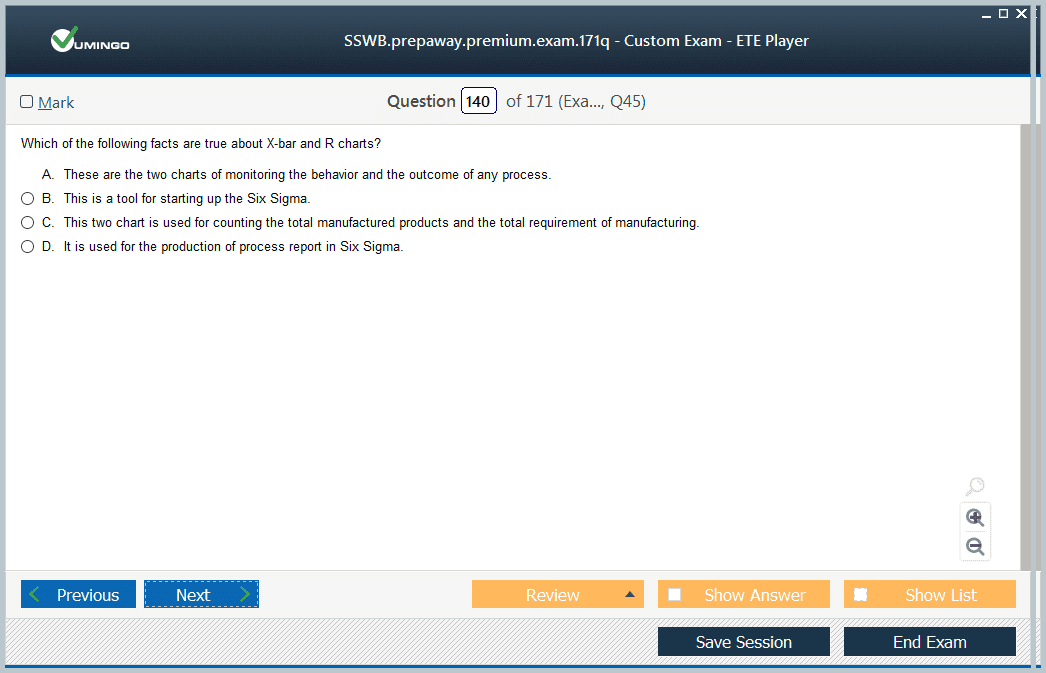

A cornerstone of the "Control" phase in the DMAIC cycle is Statistical Process Control (SPC). SPC is a method of quality control that uses statistical methods to monitor and control a process. The goal of SPC is to ensure that the process operates at its full potential to produce conforming products. A key tool in SPC is the control chart, which is a graph used to study how a process changes over time. Data are plotted in time order, and the chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit.

By observing the data points on the control chart, operators can distinguish between common cause variation, which is inherent in the process, and special cause variation, which arises from external factors. If the process is "in control," meaning only common cause variation is present, it is stable and predictable. If a special cause is detected, it signals that something has changed in the process, requiring investigation. SPC allows organizations to monitor their improved processes in real-time, ensuring that gains are sustained and that any deviations are addressed before they lead to defects.

Strategic Flexibility and Organizational Agility

In a rapidly changing market, strategic flexibility—the ability to adapt and respond to new opportunities and threats—is paramount. Lean Six Sigma directly contributes to this agility by creating streamlined, efficient, and well-understood processes. When processes are lean and free of waste, the organization can pivot more quickly. For example, a shorter product development cycle allows the company to respond faster to shifts in customer demand or to the actions of a competitor. An efficient manufacturing process can more easily adjust production volumes or switch between different products.

Furthermore, the problem-solving culture fostered by Lean Six Sigma equips the workforce with the skills to tackle new challenges as they arise. Employees become accustomed to analyzing data, identifying root causes, and implementing effective solutions. This creates a more adaptable and resilient organization that is not locked into rigid ways of working. Instead of viewing change as a threat, a Lean Six Sigma organization sees it as an opportunity for further improvement, providing a powerful and sustainable competitive advantage in any industry.

Elevating the Customer Experience

At its heart, Lean Six Sigma is a customer-centric methodology. A core principle of Lean is to define value from the perspective of the customer. Any activity that the customer is not willing to pay for is considered waste. Six Sigma complements this by focusing on reducing the variation and defects that lead to customer dissatisfaction. By implementing this methodology, organizations can consistently deliver products and services that meet or exceed customer expectations, which is the foundation of a superior customer experience.

This focus on the customer is woven throughout the DMAIC process. In the Define phase, projects are often selected based on their potential impact on customer satisfaction. The Voice of the Customer (VoC) is a critical input, gathered through surveys, feedback, and market research, to understand what customers truly value. By aligning internal processes with these external expectations, companies can create a seamless and positive experience. This leads to higher customer satisfaction scores, positive word-of-mouth, and a stronger brand reputation in the marketplace.

Building Unbreakable Customer Loyalty

Improved customer satisfaction is the first step, but the ultimate goal is to cultivate long-term customer loyalty. Loyalty is built on trust, and trust is built on consistency. The Six Sigma aspect of the methodology is particularly powerful in this regard. By using statistical tools to reduce process variation, organizations can ensure that the customer receives a consistent, predictable, and reliable experience every single time they interact with the company. Whether it is the quality of a product, the speed of a delivery, or the helpfulness of a service agent, consistency is key.

When customers know they can depend on a company to deliver high quality without fail, they are far more likely to become repeat customers. This loyal customer base is an incredibly valuable asset. Loyal customers tend to be less price-sensitive, are more likely to try new products or services from the company, and often become brand advocates, recommending the company to others. The investment in quality and consistency through Lean Six Sigma pays long-term dividends in the form of a stable and profitable customer base.

Creating a Culture that Fosters Innovation

While Lean Six Sigma is often associated with improving existing processes, its principles can also be a powerful catalyst for innovation. By streamlining daily operations and reducing the time spent on firefighting and rework, the methodology frees up valuable resources, including employee time and intellect. This newfound capacity can be redirected towards more creative and forward-thinking activities, such as developing new products, exploring new markets, or experimenting with new business models. It creates the mental and operational space for innovation to flourish.

Furthermore, the data-driven and problem-solving nature of Lean Six Sigma encourages a culture of curiosity and experimentation. Teams become adept at forming hypotheses, testing them with data, and learning from the results. This scientific approach can be applied not only to fixing existing problems but also to exploring new opportunities. It encourages employees to challenge the status quo and to look for breakthrough solutions, not just incremental improvements. This fosters an environment where innovative ideas are welcomed, tested, and implemented, driving long-term business growth.

The Voice of the Customer (VoC) Toolkit

To truly be customer-centric, organizations must have effective mechanisms for capturing and analyzing the Voice of the Customer (VoC). Lean Six Sigma projects rely heavily on this input to ensure they are focused on what truly matters. The VoC toolkit includes a variety of methods for gathering customer feedback. Proactive methods include surveys, focus groups, and interviews, which are designed to actively solicit customer opinions and expectations. Reactive methods involve analyzing data that the company already has, such as customer support tickets, online reviews, and complaint logs.

Once this qualitative data is gathered, it needs to be translated into measurable requirements. A tool often used for this is the Critical to Quality (CTQ) tree. This diagram breaks down broad customer needs into more specific and quantifiable characteristics. For example, a customer need for "fast delivery" might be broken down into CTQs like "order delivered within 24 hours" and "real-time tracking information available." This process ensures that improvement efforts are directly linked to tangible customer requirements, maximizing their impact on satisfaction and loyalty.

Design for Six Sigma (DFSS)

While the traditional DMAIC methodology is excellent for improving existing processes, Design for Six Sigma (DFSS) is a complementary approach used for designing new products, services, or processes from scratch. The goal of DFSS is to ensure that the new design meets customer requirements and is capable of performing at a Six Sigma quality level from the very beginning. This proactive approach to quality is far more efficient and cost-effective than trying to fix problems after a product has already been launched.

One common DFSS methodology is known as DMADV (Define, Measure, Analyze, Design, Verify). The initial phases are similar to DMAIC, focusing on defining project goals and understanding customer needs. The key difference is in the final stages. Instead of improving an existing process, the Design phase involves developing a new design that meets the specified requirements. The Verify phase then involves testing and validating the new design to ensure it performs as expected before it is fully implemented. DFSS ensures that quality and customer satisfaction are built into the DNA of a product or service.

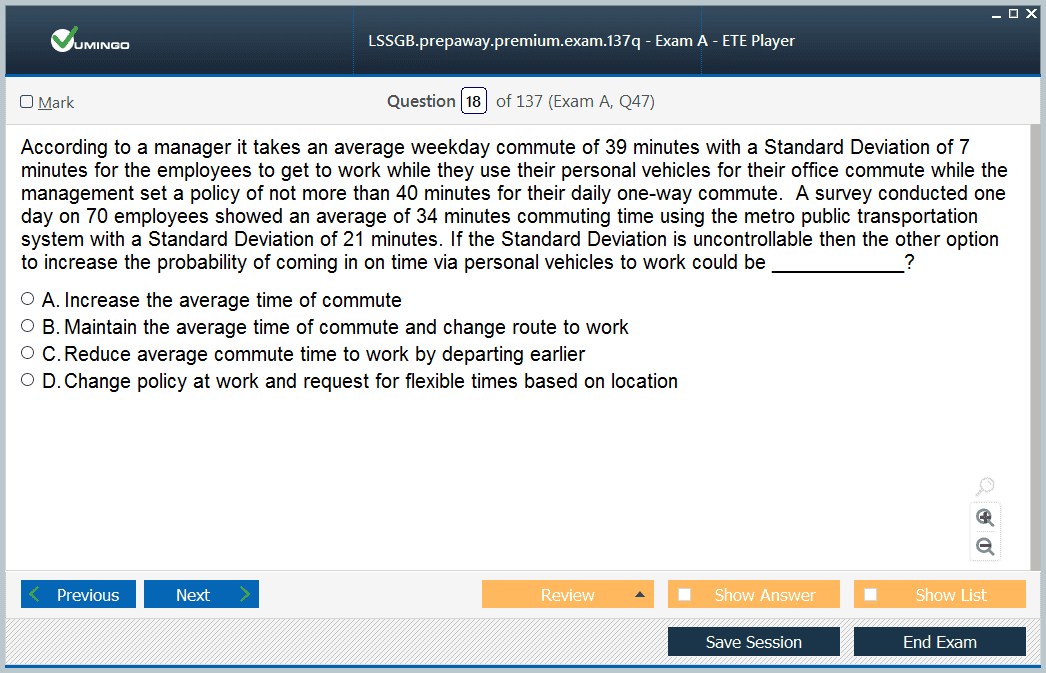

Linking Process Performance to Customer Outcomes

A powerful aspect of the Lean Six Sigma methodology is its ability to create a clear and quantitative link between internal process performance and external customer outcomes. This is achieved by identifying the key process input variables (KPIVs) that have the most significant impact on the critical to quality characteristics (CTQs) that customers care about. For example, in a call center, a customer CTQ might be "short wait time." Through data analysis, the team might discover that the key input variables affecting this are the number of staff scheduled and the average call handling time.

By understanding these relationships, the organization can focus its improvement efforts on the internal metrics that will have the biggest impact on the customer experience. This ensures that resources are not wasted on optimizing aspects of a process that are not important to the customer. This data-driven approach allows for precise control over the customer experience. By managing and controlling the key input variables, the organization can deliver a consistently high-quality output, leading to predictable and positive customer outcomes.

Empowering Employees to Drive Customer-Centric Change

A truly customer-centric organization is one where every employee feels responsible for delivering value to the customer. Lean Six Sigma helps to instill this mindset by empowering front-line employees to identify and solve problems. These employees are often the closest to the customer and have the most direct insight into their needs and pain points. Through tools like Kaizen events and Gemba walks (going to the place where work is done), leaders can engage with employees to gather their ideas for improvement.

This inclusive approach not only leads to better, more practical solutions but also boosts employee morale and engagement. When employees see that their suggestions are valued and implemented, they become more invested in the success of the organization and more committed to satisfying the customer. They move from being passive participants in a process to active owners of it. This creates a powerful, self-sustaining cycle of continuous improvement that is driven by a shared commitment to customer excellence from the ground up.

Enhancing Workforce Productivity and Morale

Lean Six Sigma is fundamentally about making work easier, smoother, and more effective. When processes are inefficient and full of waste, it leads to frustration and disengagement among employees. They spend their time fighting fires, dealing with rework, or waiting for information and materials. By applying Lean Six Sigma principles to streamline these processes, organizations remove these daily frustrations. This allows employees to focus on value-adding activities, which is inherently more satisfying and leads to a natural increase in productivity.

Furthermore, the methodology fosters a collaborative and inclusive work environment. Improvement projects are typically carried out by cross-functional teams, breaking down departmental silos and encouraging communication. Employees at all levels are encouraged to contribute their ideas and solutions. This involvement is incredibly empowering. When employees feel that their knowledge is respected and that they have the ability to make a meaningful difference in their work, it leads to a significant boost in morale, job satisfaction, and overall engagement with the company's mission.

Developing Strong Managerial and Leadership Skills

The journey of implementing Lean Six Sigma provides a powerful development platform for managers and leaders within an organization. The structured, data-driven nature of the methodology equips them with a valuable new set of skills. They learn how to analyze complex problems, interpret statistical data, and make informed decisions based on evidence rather than intuition. This enhances their critical thinking and problem-solving abilities, which are essential for effective leadership in any context.

Moreover, leading a Lean Six Sigma project requires strong change management and team facilitation skills. Managers learn how to build and lead cross-functional teams, how to motivate employees through a change process, and how to communicate effectively with stakeholders at all levels. The belt certification system (Yellow, Green, Black Belt) provides a clear and structured path for developing these competencies. As individuals progress through the belt levels, they take on increasingly complex projects and leadership responsibilities, creating a pipeline of skilled and capable leaders for the organization.

Cultivating a Culture of Continuous Improvement

Perhaps the most profound and lasting benefit of Lean Six Sigma is its ability to transform an organization's culture. When implemented successfully, it moves a company from a reactive, "firefighting" mindset to a proactive, problem-solving one. It instills a belief that every process can be improved and that everyone has a role to play in that improvement. This creates a culture of continuous improvement, or "Kaizen," where the pursuit of excellence becomes a shared value woven into the fabric of the organization.

This cultural shift does not happen overnight. It requires consistent support from leadership, ongoing training, and the celebration of successes. However, once this culture takes root, it becomes a powerful, self-sustaining engine for growth and innovation. Employees are no longer afraid to point out problems; instead, they see them as opportunities for improvement. The organization becomes a learning entity, constantly adapting, evolving, and getting better. This proactive and positive culture is a significant competitive advantage that is very difficult for rivals to replicate.

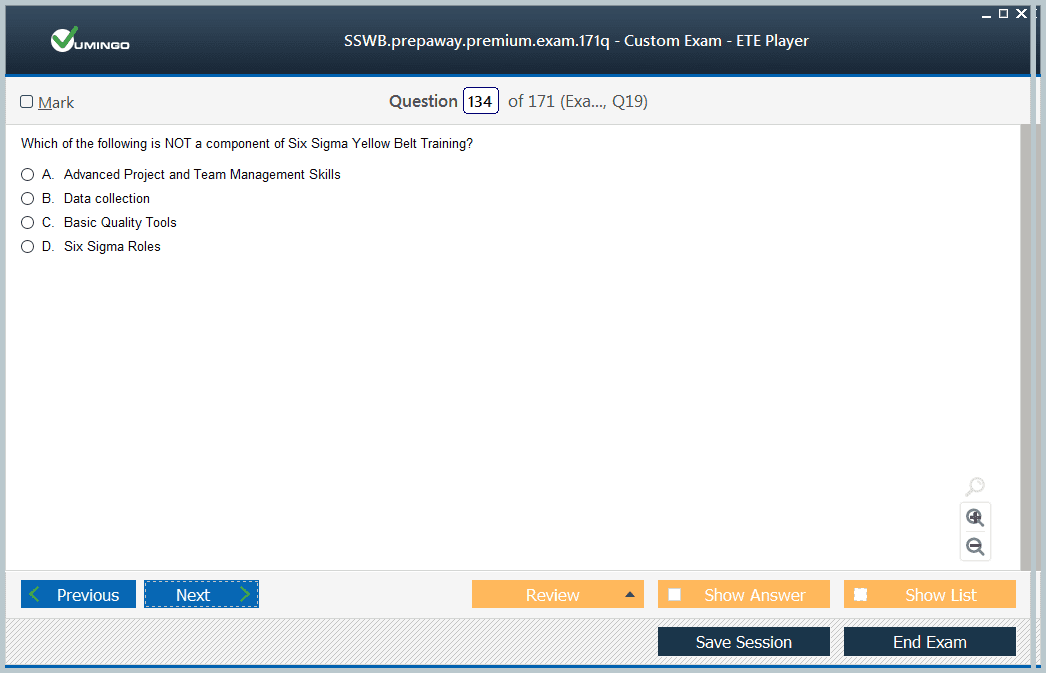

The Lean Six Sigma Belt System Explained

The belt system provides a structured framework for skill development and project leadership within a Lean Six Sigma program. Each level represents a different degree of training and responsibility. Yellow Belts typically receive basic training in the fundamental concepts and tools. They often participate as team members on projects and help with data collection. Green Belts receive more extensive training and are capable of leading smaller-scale improvement projects within their own functional areas, often under the guidance of a Black Belt.

Black Belts are highly trained experts who dedicate their full time to leading complex, cross-functional improvement projects. They possess a deep understanding of the statistical tools and act as coaches and mentors for Green Belts. At the highest level are Master Black Belts, who are responsible for the strategic deployment of Lean Six Sigma across the organization. They train and mentor Black Belts, advise senior leadership, and ensure that the improvement program is aligned with the company's strategic goals. This system creates a clear career path and a robust internal support structure for the initiative.

Empowerment Through Gemba Walks

A core principle of Lean is "Genchi Genbutsu," which translates to "go and see for yourself." In practice, this is often done through Gemba walks. "Gemba" is the Japanese term for "the real place," which in a business context means the place where value is created, such as the factory floor, the call center, or the development lab. During a Gemba walk, leaders and managers go to the Gemba not to find fault or give orders, but to observe processes, ask questions, and learn from the people who do the work every day.

This practice is a powerful tool for empowering employees and fostering a culture of respect. It shows front-line staff that their work is important and that leadership is genuinely interested in understanding their challenges. It helps break down the barriers between management and the workforce, fostering a more collaborative environment. The insights gained during a Gemba walk are often invaluable, providing a real-world perspective that cannot be obtained from looking at reports or spreadsheets. It is a cornerstone of effective Lean leadership.

Breaking Down Silos with Cross-Functional Teams

Many traditional organizations are structured in functional silos, such as marketing, finance, and operations. While this allows for deep expertise in each area, it can also lead to poor communication, conflicting priorities, and inefficient processes that span multiple departments. Lean Six Sigma projects are almost always conducted by cross-functional teams. This means that individuals from all the relevant departments involved in a process are brought together to work on a common goal.

This collaborative approach has numerous benefits. It ensures that the team has a holistic understanding of the entire process, from start to finish. It brings diverse perspectives to the problem-solving effort, often leading to more creative and robust solutions. Most importantly, it breaks down the "us versus them" mentality that can exist between departments. By working together on a shared problem, team members build relationships and a better appreciation for each other's roles and challenges, fostering a more cohesive and collaborative organization.

Achievement Through Standardization

While innovation is important, consistency and reliability are the bedrock of quality. Lean Six Sigma helps organizations achieve this through the development and implementation of standardized work. Standardized work is the practice of documenting the best, safest, and most efficient way to perform a particular task or process. It captures the collective knowledge of the workforce and establishes a clear baseline for performance. This ensures that every employee performs the task in the same optimal way, leading to consistent and predictable outcomes.

Standardization is not about stifling creativity; it is about creating a stable foundation upon which to build further improvements. Once a standard is in place, it becomes the new baseline. If an employee has an idea for a better way to do the work, that new method can be tested. If it proves to be superior, the standard is updated for everyone. This cycle of standardizing and then improving is a key engine of the continuous improvement culture, ensuring that hard-won gains are not lost and that the organization continues to learn and evolve.

Driving Sustainable Organizational Growth

The culmination of all the benefits discussed—from cost savings and improved quality to enhanced customer loyalty and employee morale—is sustainable organizational growth. Lean Six Sigma provides a robust framework for building a stronger, more resilient, and more profitable business. By improving operational efficiency, the organization can increase its capacity and throughput, allowing it to serve more customers and expand its market share without a proportional increase in costs. This creates a scalable model for growth.

Furthermore, the focus on customer satisfaction and loyalty creates a stable revenue base and a strong brand reputation, which are essential for long-term success. The cost savings achieved through waste reduction can be reinvested into strategic initiatives like research and development, marketing, or expansion into new markets. The culture of continuous improvement ensures that the organization does not become complacent but continues to adapt and evolve, staying ahead of the competition. Lean Six Sigma is not a one-time fix; it is a long-term strategy for building a thriving enterprise.

The Universal Applicability Across Global Industries

A common misconception is that Lean Six Sigma is only applicable to manufacturing. While its roots are in production, the principles and tools of the methodology are universally applicable to any process in any industry. At its core, Lean Six Sigma is about identifying problems, analyzing root causes with data, and implementing effective solutions. These are challenges that exist in every sector, whether it is healthcare, finance, information technology, government, or education. The "product" may differ, but the underlying processes are ripe for improvement.

For example, in a hospital, Lean Six Sigma can be used to reduce patient wait times, prevent medication errors, and streamline the patient discharge process. In a bank, it can be applied to speed up loan application processing and reduce errors in financial transactions. In a software company, it can improve the development lifecycle and reduce the number of bugs in code. This versatility is one of the greatest strengths of the methodology, making it a valuable and relevant skill set for professionals in any field, anywhere in the world.

Lean Six Sigma in Healthcare

The healthcare industry is a prime example of a non-manufacturing sector that has seen immense benefits from Lean Six Sigma. The stakes in healthcare are incredibly high, as process inefficiencies and errors can have direct consequences on patient safety and outcomes. Hospitals and clinics have used the methodology to tackle a wide range of challenges. For instance, value stream mapping has been used to analyze the entire patient journey, from admission to discharge, identifying bottlenecks and delays that lead to long wait times and frustrated patients.

Six Sigma's DMAIC framework has been instrumental in patient safety initiatives. Projects have focused on reducing hospital-acquired infections, preventing medication administration errors, and improving the accuracy of surgical procedures. By applying rigorous, data-driven analysis to these critical processes, healthcare organizations have been able to achieve significant improvements in the quality and safety of care. The Lean principle of 5S has also been widely adopted to organize operating rooms and supply closets, ensuring that medical staff have the tools they need, when they need them.

Lean Six Sigma in the Financial Sector

The financial services industry, which includes banking, insurance, and investment firms, is another area where Lean Six Sigma has made a significant impact. These organizations are characterized by complex, high-volume transactional processes where accuracy and efficiency are paramount. Banks have used Lean Six Sigma to streamline the mortgage application and approval process, reducing the cycle time from weeks to days. This not only improves customer satisfaction but also allows the bank to process more loans and increase revenue.

In the insurance sector, the methodology has been applied to the claims processing value stream. By mapping out the process and eliminating non-value-adding steps and delays, companies have been able to reduce the time it takes to settle a claim, a key driver of customer loyalty. Investment firms have used the principles to reduce errors in trade execution and improve the efficiency of their back-office operations. In an industry driven by data and regulation, the structured, evidence-based approach of Lean Six Sigma is a natural fit for driving operational excellence.

Sustaining Gains for Long-Term Success

Implementing improvements is only half the battle; the real challenge is sustaining those gains over the long term. The "Control" phase of the DMAIC methodology is specifically designed to address this challenge. During this phase, the project team develops a control plan that documents the new process, outlines the key metrics to be monitored, and specifies the actions to be taken if the process deviates from the desired performance level. This plan effectively transfers ownership of the improved process from the project team back to the front-line process owners.

Tools like Statistical Process Control (SPC) charts are often used to monitor the process in real-time, providing an early warning system for any potential issues. Standardized work and regular process audits also play a crucial role in preventing the process from reverting to its old, inefficient ways. Sustaining gains requires discipline and consistent leadership focus, but it is essential for realizing the full, long-term financial and cultural benefits of a Lean Six Sigma program. Without a robust control plan, even the most successful improvement projects can quickly lose their impact.

A Final Perspective:

In conclusion, the journey of adopting Lean Six Sigma is a transformative one. It begins with tackling specific operational problems—reducing errors, cutting waste, and speeding up processes. These initial projects deliver tangible financial returns and build momentum for the initiative. As the methodology becomes more deeply embedded, its impact expands to enhance strategic planning, risk management, and customer loyalty. It creates a more agile and competitive organization that is attractive to business partners and resilient to market changes.

Ultimately, the most profound transformation occurs at the cultural level. Lean Six Sigma cultivates a high-performing workforce where employees are empowered, leaders are developed, and the entire organization is aligned around a shared commitment to continuous improvement and customer value. This cultural shift from reactive problem-solving to proactive excellence is the ultimate benefit, creating a sustainable foundation for growth and success in any industry. It is a comprehensive system for achieving and maintaining a true competitive advantage in the global marketplace.

Lean Six Sigma certification practice test questions and answers, training course, study guide are uploaded in ETE files format by real users. Study and pass Six Sigma Lean Six Sigma certification exam dumps & practice test questions and answers are the best available resource to help students pass at the first attempt.