Pass Six Sigma Lean Six Sigma Green Belt Certification Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

LSSGB Premium Bundle

- Premium File 162 Questions & Answers. Last update: Feb 11, 2026

- Training Course 212 Video Lectures

- Study Guide 664 Pages

LSSGB Premium Bundle

- Premium File 162 Questions & Answers

Last update: Feb 11, 2026 - Training Course 212 Video Lectures

- Study Guide 664 Pages

Purchase Individually

Premium File

Training Course

Study Guide

LSSGB Exam - Lean Six Sigma Green Belt

| Download Free LSSGB Exam Questions |

|---|

Six Sigma Lean Six Sigma Green Belt Certification Practice Test Questions and Answers, Six Sigma Lean Six Sigma Green Belt Certification Exam Dumps

All Six Sigma Lean Six Sigma Green Belt certification exam dumps, study guide, training courses are prepared by industry experts. Six Sigma Lean Six Sigma Green Belt certification practice test questions and answers, exam dumps, study guide and training courses help candidates to study and pass hassle-free!

The Foundations of Lean Six Sigma Green Belt Role

In any competitive business landscape, the pursuit of excellence is a constant endeavor. Organizations across all sectors are continually seeking ways to enhance their operations, deliver higher quality products and services, and maximize value for their customers. This is the realm of process improvement, a systematic approach to identifying, analyzing, and improving existing business processes to meet new goals and objectives. It is a discipline dedicated to eliminating inefficiencies, reducing costs, and fostering a culture of quality and continuous growth.

The core idea behind process improvement is that all work is part of a process, and every process can be made better. Whether it is manufacturing a product, onboarding a new employee, or handling a customer service inquiry, there is a sequence of steps that can be refined. Without a structured methodology, efforts to improve can be haphazard, based on guesswork rather than data. This can lead to wasted resources and solutions that fail to address the true root cause of a problem, making a formal framework essential for achieving meaningful and sustainable results.

This is where methodologies like Lean Six Sigma provide immense value. They offer a proven, data-driven framework that transforms process improvement from an art into a science. By equipping professionals with a specific set of tools and a logical roadmap, these methodologies empower them to dissect complex problems, identify the sources of waste and variation, and implement effective solutions that deliver measurable business impact. Understanding this foundational need for structured improvement is the first step in appreciating the career benefits that a certification like the Lean Six Sigma Green Belt offers.

What is Lean?

The Lean methodology has its roots in the Toyota Production System, a philosophy developed in Japan after World War II. At its core, Lean is a relentless focus on the elimination of waste to maximize value. Value is defined from the perspective of the customer; any action or process step that the customer is not willing to pay for is considered waste. The primary goal of Lean is to create a smooth, efficient flow of value to the customer by systematically identifying and removing these non-value-added activities from a process.

Lean thinking identifies eight specific types of waste, often remembered by the acronym DOWNTIME. These are Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing. For example, waiting for a signature, producing more reports than are needed, or unnecessary movement of materials are all forms of waste that add cost and time to a process without adding any value for the customer. Lean practitioners learn to see these wastes in their daily work and are empowered to eliminate them.

Implementing Lean principles involves using a variety of tools and techniques. Value Stream Mapping is used to visualize an entire process from start to finish, identifying every step and classifying it as value-added or non-value-added. The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) is used to create a clean, organized, and efficient workplace. The concept of Kaizen, or continuous improvement, fosters a culture where all employees are encouraged to make small, incremental improvements to their processes on an ongoing basis.

Ultimately, Lean is not just a toolkit but a cultural mindset. It promotes a system where processes are streamlined, lead times are reduced, and the focus is always on delivering precisely what the customer wants, when they want it, with the least amount of effort and resources. A professional trained in Lean principles brings a powerful perspective to any organization, capable of identifying hidden inefficiencies and driving a culture of operational excellence.

What is Six Sigma?

While Lean focuses on speed and waste elimination, Six Sigma is a data-driven methodology focused on reducing variation and eliminating defects. Originally developed by Motorola in the 1980s, Six Sigma is a disciplined, statistical-based approach to process improvement. The name "Six Sigma" itself is a statistical term that refers to a process that produces a mere 3.4 defects per million opportunities. This represents a level of quality that is virtually perfect, and it is the aspirational goal that the methodology strives for.

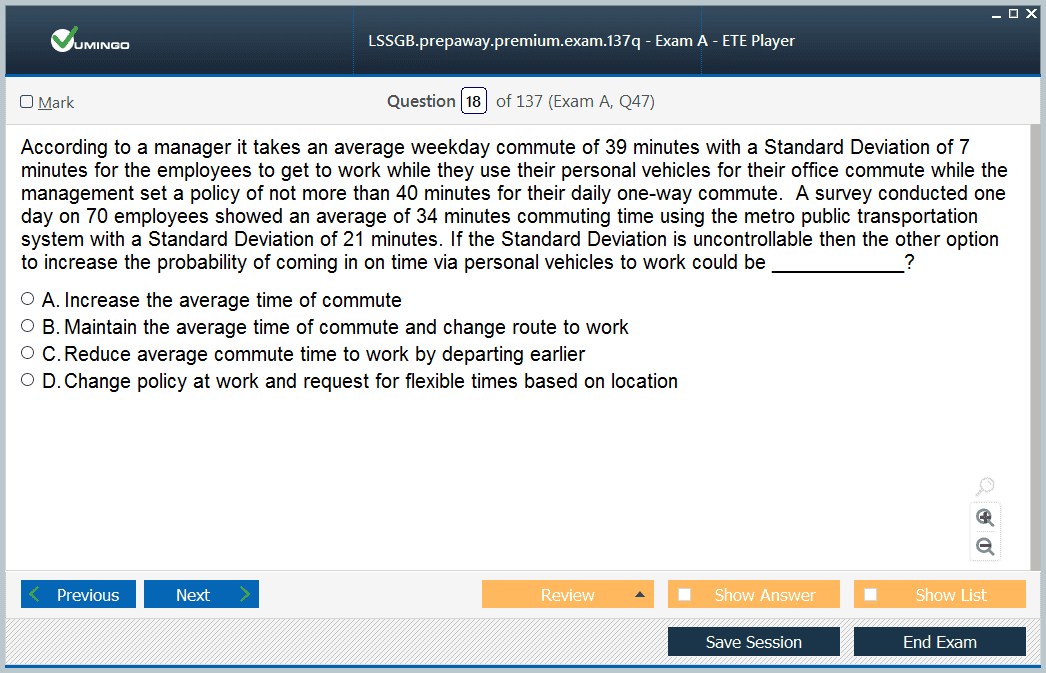

The fundamental principle of Six Sigma is that every process has a certain amount of inherent variation. If you measure the output of any process, the results will not always be identical. This variation can lead to defects and unpredictable outcomes. Six Sigma aims to understand the sources of this variation and bring them under control. By reducing variation, the process becomes more consistent, reliable, and capable of meeting customer requirements every single time. Decisions are not based on intuition or hunches, but on verifiable data and statistical analysis.

The heart of the Six Sigma methodology is a structured five-phase framework known as DMAIC, which stands for Define, Measure, Analyze, Improve, and Control. This framework provides a logical and rigorous roadmap for solving problems. In the Define phase, the problem and project goals are clearly identified. In the Measure phase, data is collected to establish a baseline of the process's current performance. The Analyze phase uses statistical tools to identify the root cause of the problem. In the Improve phase, solutions are developed and implemented, and the Control phase ensures the gains are sustained over time.

A professional with Six Sigma training learns how to apply this rigorous DMAIC methodology to solve complex business problems. They become skilled in using statistical tools to analyze data, in identifying root causes rather than just symptoms, and in implementing robust solutions that are proven to be effective. This ability to make data-driven decisions and deliver quantifiable results is a highly sought-after skill in today's business environment, making Six Sigma a powerful addition to anyone's professional capabilities.

The Synergy of Lean Six Sigma

Over time, practitioners realized that the Lean and Six Sigma methodologies, while distinct in their origins and primary focus, are highly complementary. Lean's emphasis on eliminating waste and increasing process speed provides a powerful framework for identifying inefficiencies, while Six Sigma's focus on reducing variation and defects provides the statistical rigor to solve complex problems that cause that waste. This realization led to the integration of the two approaches into a single, comprehensive methodology known as Lean Six Sigma (LSS).

The combination of Lean and Six Sigma creates a powerful synergy. Lean tools are often used to identify areas of waste and quickly streamline a process, achieving significant improvements in a short amount of time. However, some problems are more complex and have root causes that are not immediately obvious. This is where the statistical rigor of the Six Sigma DMAIC framework comes into play. It provides the tools to tackle the more stubborn sources of variation and defects that Lean tools alone may not be able to address.

Essentially, Lean Six Sigma allows a practitioner to first make a process more efficient by removing the obvious waste, and then make it more effective by reducing the variation in its output. It answers two critical questions for any process: "Are we doing things right?" which is addressed by Six Sigma's focus on quality and consistency, and "Are we doing the right things?" which is addressed by Lean's focus on value and waste elimination. This dual approach ensures that improvements are not only statistically sound but also directly contribute to a faster, more streamlined flow of value to the customer.

For a professional, being certified in Lean Six Sigma means possessing a comprehensive and versatile problem-solving toolkit. They are not limited to just one approach but can flexibly apply the right tools to the right problem. This makes them exceptionally valuable to organizations, as they can lead a wide range of improvement initiatives, from quick-win Kaizen events to complex, data-intensive DMAIC projects, all aimed at achieving significant and sustainable business results.

The Role of the Green Belt

Within the Lean Six Sigma framework, practitioners are certified at different levels, known as "belts," similar to the ranking system in martial arts. The Lean Six Sigma Green Belt is a crucial level in this hierarchy. A Green Belt is a professional who has been trained in the Lean Six Sigma methodology and is capable of leading small-to-medium-sized improvement projects. They are the workhorses of an organization's continuous improvement program, dedicating a portion of their time to process improvement activities while still performing their regular job functions.

The primary role of a Green Belt is to apply the DMAIC methodology to solve problems within their own functional areas. They are equipped with the tools to define a project scope, gather and analyze data, identify root causes, and implement and control solutions. Unlike a Black Belt, who may work on large, cross-functional projects full-time, a Green Belt typically focuses on projects that are more localized but still deliver a significant impact on quality, cost, or customer satisfaction.

In addition to leading their own projects, Green Belts often play a vital supporting role on larger projects led by a Lean Six Sigma Black Belt. They may be responsible for specific tasks within the project, such as collecting data, creating process maps, or participating in brainstorming sessions. This collaborative structure allows an organization to deploy its process improvement resources effectively, with Black Belts tackling the most complex enterprise-wide issues and Green Belts driving improvement at the departmental level.

Becoming a Green Belt is often the first major step for a professional on their process improvement journey. The training provides them with a robust set of analytical and problem-solving skills that are immediately applicable to their daily work. It empowers them to move beyond simply identifying problems and gives them the confidence and the capability to lead a team to solve those problems in a structured, data-driven manner. This ability to drive tangible change is what makes the Green Belt certification so valuable for career advancement.

The Six Sigma Belt Hierarchy

To fully appreciate the role of a Green Belt, it is helpful to understand the entire Lean Six Sigma belt hierarchy. Each level represents a greater degree of knowledge, expertise, and responsibility within the methodology. This structured system ensures that there is a clear path for development and a well-defined set of roles for deploying a continuous improvement strategy across an organization.

The journey often begins with the Yellow Belt. A Yellow Belt has a basic understanding of Lean Six Sigma concepts. They are typically not project leaders but are valuable team members who can contribute to projects led by Green Belts or Black Belts. They are trained to identify waste in their own work processes and can participate effectively in improvement events. The Yellow Belt training provides a foundational awareness of the methodology for the general workforce.

The next level is the Green Belt, which represents a significant step up in expertise. As previously discussed, Green Belts are capable of leading their own improvement projects. They have a deeper understanding of the DMAIC framework and are skilled in using a wide range of statistical and problem-solving tools. They are the engine of many improvement initiatives within a company, driving change at a tactical level.

Above the Green Belt is the Black Belt. A Black Belt is a full-time process improvement expert who leads complex, high-impact projects that often span multiple departments. They possess an advanced understanding of statistical analysis and the entire LSS toolkit. A key part of the Black Belt role is also to mentor and coach Green Belts, helping them with their projects and fostering their development. They act as agents of change and are leaders in an organization's continuous improvement culture.

At the top of the hierarchy is the Master Black Belt. A Master Black Belt is a seasoned expert who is responsible for the strategic deployment of Lean Six Sigma across the entire enterprise. They train and mentor Black Belts, advise senior leadership on the improvement strategy, and ensure that the LSS program is aligned with the organization's overall business goals. Understanding this hierarchy helps a professional see the Green Belt certification not just as an endpoint, but as a significant milestone on a path of continuous professional growth.

Core Principles of a Green Belt

Beyond the tools and the DMAIC methodology, a Lean Six Sigma Green Belt certification instills a set of core principles that shape a professional's approach to their work. These principles form a powerful mindset that is focused on delivering value and driving excellence. The first and most important principle is a relentless focus on the customer. A Green Belt learns to view every process through the eyes of the customer, understanding what they value and what constitutes a defect in their experience. This customer-centric approach ensures that improvement efforts are always aimed at what matters most.

Another core principle is making decisions based on data and facts, not assumptions. A Green Belt is trained to be skeptical of anecdotal evidence and to seek out objective data to understand a problem. They learn how to collect clean data, analyze it using statistical methods, and present their findings in a clear and compelling way. This data-driven mindset removes emotion and guesswork from the problem-solving process, leading to more effective and sustainable solutions.

A Green Belt also embraces a proactive, preventative approach to problems. Instead of constantly fighting fires and reacting to issues as they arise, they are trained to use data to identify the root causes of problems and implement solutions that prevent them from recurring. This shift from a reactive to a proactive mindset is transformative, helping organizations to move from a state of constant crisis management to one of controlled, predictable performance.

Finally, the Green Belt philosophy promotes collaboration and teamwork. Improvement projects are rarely a solo endeavor. A Green Belt learns how to lead and facilitate a team of subject matter experts, harnessing their collective knowledge to analyze a process and develop solutions. This principle recognizes that the people closest to the work often have the best insights into how to improve it. By fostering a collaborative environment, a Green Belt can drive engagement and ensure that the solutions developed are practical and widely accepted.

Introduction to the DMAIC Framework

The heart of the Six Sigma methodology, and the primary roadmap for any Green Belt project, is the DMAIC framework. DMAIC is a systematic, five-phase approach to problem-solving that provides a structured pathway from identifying a problem to implementing a lasting solution. The acronym stands for Define, Measure, Analyze, Improve, and Control. This framework is what distinguishes Lean Six Sigma from simple brainstorming or trial-and-error approaches; it is a disciplined and data-driven cycle that ensures all aspects of a problem are thoroughly investigated.

The power of the DMAIC framework lies in its logical progression. Each phase has a specific set of objectives and deliverables that must be completed before moving on to the next. This gated process prevents teams from jumping to solutions before the problem and its root causes are fully understood. For a Green Belt, mastering the DMAIC cycle is the most critical aspect of their training. It provides them with a repeatable and reliable method for tackling any process improvement challenge they may face.

The DMAIC cycle is inherently iterative. While it is presented as a linear sequence, in practice, there may be a need to revisit earlier phases as new information is discovered. For example, during the Analyze phase, the team might realize that the problem was not defined correctly, requiring them to go back to the Define phase to refine the project scope. This flexibility, combined with its rigorous structure, makes DMAIC an incredibly robust tool for driving meaningful and sustainable process improvement.

Throughout the DMAIC journey, a Green Belt will utilize a wide variety of specific tools and techniques that are appropriate for each phase. The training for certification focuses heavily on teaching a practitioner not only how to use these tools but, more importantly, when to use them. This part will explore each of the five phases in detail, outlining their purpose and highlighting some of the key tools that a Green Belt will learn to master.

The Define Phase

The Define phase is the critical starting point for any Lean Six Sigma project. The primary goal of this phase is to clearly articulate the problem that needs to be solved, the goals of the project, and the scope of the improvement effort. A poorly defined project is almost certain to fail, as the team will lack a clear direction and focus. A well-executed Define phase sets the project up for success by ensuring that everyone involved has a shared understanding of what they are trying to achieve and why it is important.

The most important deliverable of this phase is the Project Charter. The Project Charter is a formal document that serves as the contract for the project. It typically includes a clear problem statement that describes the issue and its impact on the business. It also includes a goal statement, which should be SMART (Specific, Measurable, Achievable, Relevant, and Time-bound). The charter also defines the project scope, outlining what is in and out of the project's boundaries, and lists the project team members and key stakeholders.

Another key tool used in the Define phase is the Voice of the Customer (VOC) analysis. This involves gathering direct input from customers to understand their needs, expectations, and what they consider to be a defect. Techniques for gathering VOC can include surveys, interviews, focus groups, and analysis of complaint data. This information is crucial for ensuring that the project's goals are directly aligned with improving the customer experience.

To understand the high-level boundaries of the process being improved, teams often create a SIPOC diagram. SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. This simple, one-page diagram identifies the key suppliers who provide inputs to the process, the major steps in the process itself, the key outputs it produces, and the customers who receive those outputs. It provides a valuable context for the project and helps to define its scope. A successful Define phase results in a clear, focused, and approved Project Charter that provides the mandate for the team to proceed.

The Measure Phase

Once the project is clearly defined, the team moves into the Measure phase. The primary objective of this phase is to collect data to understand the current performance of the process and establish a factual baseline. This is where the data-driven nature of Lean Six Sigma truly begins to take shape. The baseline measurement provides a starting point against which all future improvements will be compared, allowing the team to quantify the impact of their solutions.

A critical first step in the Measure phase is to create a detailed process map. While the SIPOC in the Define phase provided a high-level view, a detailed process map, often in the form of a flowchart, documents every single step, decision point, and handoff in the process. This exercise helps the team to visualize the process as it currently exists and often reveals immediate opportunities for improvement, such as redundant steps or unnecessary loops.

With a clear understanding of the process steps, the team then develops a Data Collection Plan. This is a formal document that specifies exactly what data will be collected, how it will be measured, who will collect it, and over what period. A good data collection plan is essential for ensuring that the data gathered is accurate, consistent, and relevant to the problem being investigated. It also includes an operational definition for each metric to ensure everyone is measuring in the same way.

Before beginning the full-scale data collection, it is crucial to perform a Measurement System Analysis (MSA). An MSA is a study designed to verify that the measurement system itself is reliable. If the measurement system is producing inaccurate or inconsistent readings, then the data collected will be useless, and any conclusions drawn from it will be flawed. An MSA ensures that the variation observed in the data is due to the process itself, not the way it is being measured. At the end of the Measure phase, the team has a clear, data-backed understanding of the process's current performance and its stability.

The Analyze Phase

With a reliable set of baseline data in hand, the project moves into the Analyze phase. The goal of this phase is to use the data collected to identify, validate, and prioritize the root causes of the problem. This is the investigative heart of the DMAIC process. It is a common mistake for teams to jump from measuring a problem directly to brainstorming solutions. The Analyze phase forces a disciplined approach, ensuring that solutions are targeted at the true underlying causes, not just the visible symptoms.

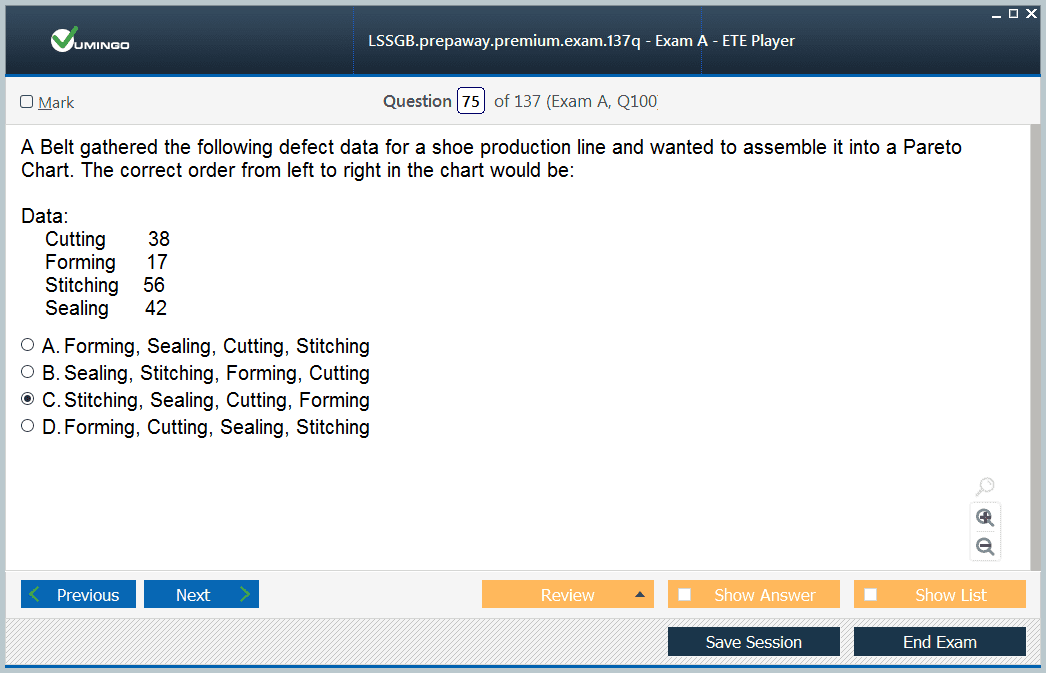

The phase often begins with a graphical analysis of the data. Tools like histograms, run charts, and Pareto charts are used to visualize the data, identify patterns, and narrow down the focus of the investigation. A Pareto chart, for example, is based on the 80/20 rule and can help a team to identify the "vital few" causes that are responsible for the majority of the problems. This allows the team to focus its efforts where they will have the greatest impact.

To explore all the potential causes of a problem, teams use root cause analysis tools. The Fishbone Diagram, also known as an Ishikawa or Cause-and-Effect Diagram, is a brainstorming tool used to organize potential causes into categories, such as People, Process, and Technology. Another powerful and simple technique is the 5 Whys, which involves repeatedly asking the question "Why?" to drill down past the symptoms to the ultimate root cause of an issue.

For more complex problems, Green Belts may use more advanced statistical tools, such as hypothesis testing and regression analysis, to statistically validate the relationship between potential causes and the problem effect. The goal is to move from a long list of potential causes to a short, validated list of proven root causes. By the end of the Analyze phase, the team should be able to say with confidence, based on data, exactly what is causing the problem they set out to solve.

The Improve Phase

Once the root causes have been identified and validated in the Analyze phase, the team is finally ready to move into the Improve phase. The objective here is to brainstorm, evaluate, and implement solutions that directly address these root causes. This is often the most creative phase of the DMAIC cycle, as the team works together to develop innovative ways to improve the process.

The phase typically starts with brainstorming sessions to generate a wide range of potential solutions for each of the identified root causes. It is important to encourage open thinking at this stage and not to dismiss any ideas prematurely. Once a comprehensive list of potential solutions has been generated, the team must then evaluate them against a set of criteria, such as effectiveness, cost to implement, time to implement, and potential risks. This allows the team to prioritize and select the best solutions to move forward with.

Before implementing a solution on a large scale, it is often a wise practice to conduct a pilot test. A pilot is a small-scale implementation of the proposed change in a controlled environment. This allows the team to test the effectiveness of the solution, identify any unintended consequences, and refine the implementation plan before a full rollout. Data is collected during the pilot to confirm that the solution is indeed producing the desired improvement.

Another valuable tool used in the Improve phase is the Failure Mode and Effects Analysis (FMEA). An FMEA is a risk assessment tool that is used to proactively identify all the things that could potentially go wrong with the new, improved process. For each potential failure, the team assesses its severity, its likelihood of occurring, and the ability to detect it. This allows the team to build preventative measures into the new process, ensuring it is robust and reliable from the start.

The Control Phase

The final phase of the DMAIC methodology is the Control phase. The objective of this phase is to ensure that the improvements achieved in the Improve phase are sustained over the long term. It is a common pitfall for teams to declare victory after implementing a solution, only to find that the process slowly reverts to its old ways over time. The Control phase is designed to prevent this by putting mechanisms in place to maintain the gains and ensure the new process becomes the standard.

A key deliverable of the Control phase is the Control Plan. This document provides a summary of the new process and outlines the key metrics that will be monitored to ensure it remains in a state of control. The Control Plan specifies how these metrics will be measured, who is responsible for monitoring them, and what actions should be taken if the process starts to deviate from its expected performance. It serves as a guide for the process owner to manage the improved process going forward.

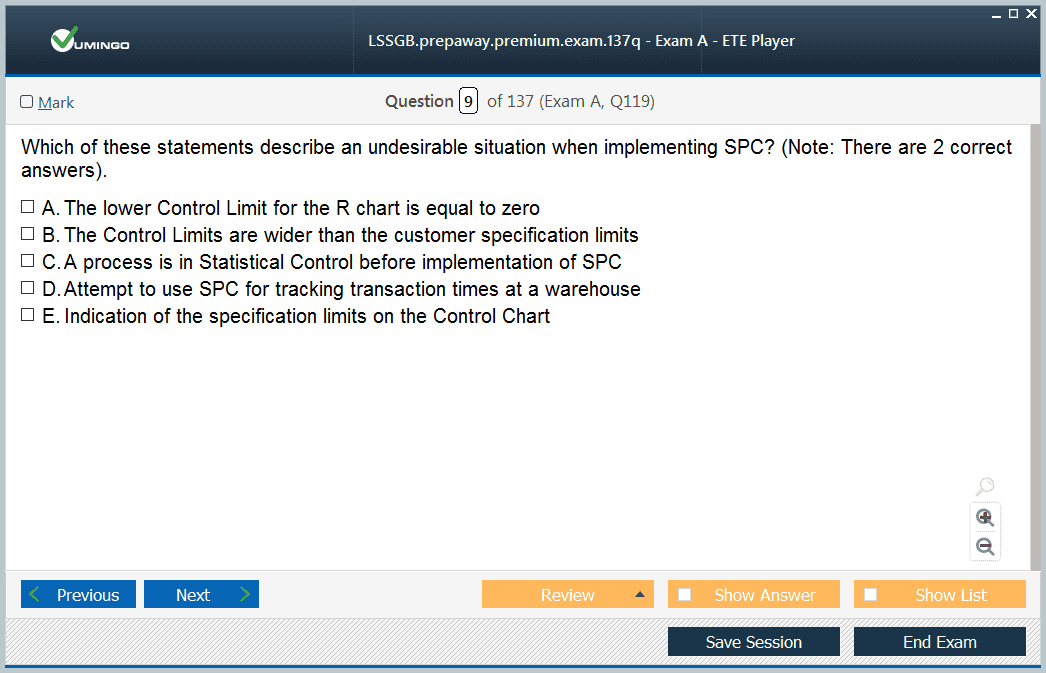

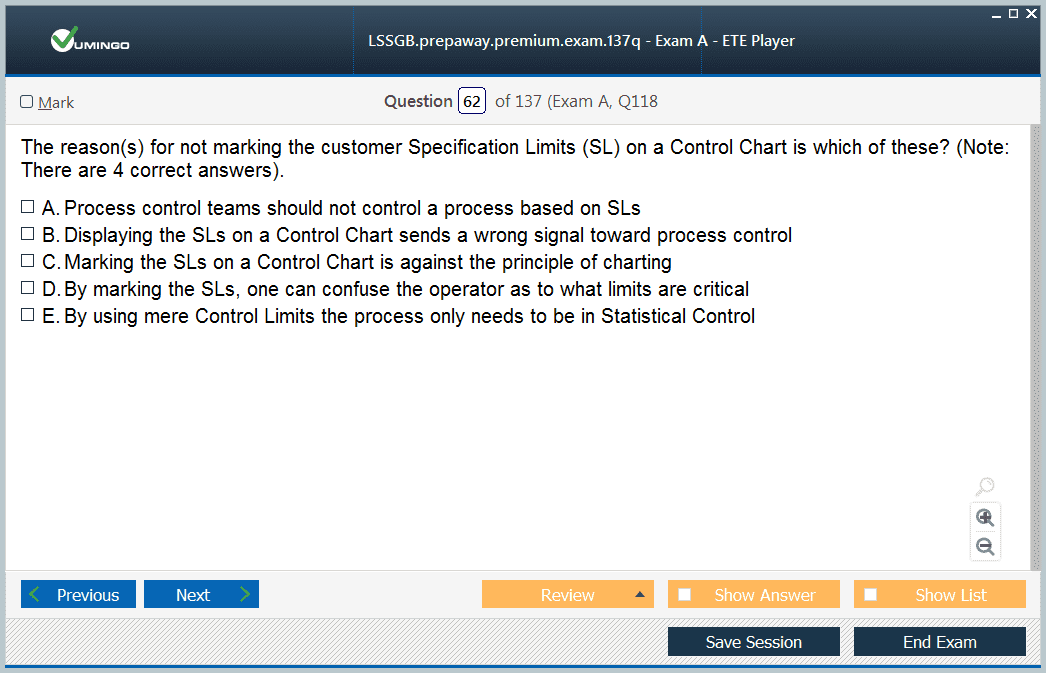

To visually monitor the performance of the new process, teams often implement Statistical Process Control (SPC) charts, also known as control charts. A control chart is a run chart with statistically calculated upper and lower control limits. By plotting the process data over time, the chart can distinguish between normal, inherent variation (common cause) and unusual events that indicate a problem (special cause). This allows the process owner to intervene quickly if the process becomes unstable.

Finally, the Control phase involves updating all relevant process documentation, such as standard operating procedures (SOPs), work instructions, and training materials, to reflect the new way of working. It is crucial that all employees involved in the process are trained on the new procedures. The project is then formally closed out, and ownership of the improved process is transferred to the process owner. A successful Control phase ensures that the hard work of the project team translates into lasting business value.

Key Tools for a Green Belt

Throughout the DMAIC journey, a Lean Six Sigma Green Belt will become proficient in using a wide variety of tools. While we have touched on several of them, it is worth highlighting a few of the most versatile and commonly used tools in a Green Belt's toolkit. These tools are not just for LSS projects; they are powerful analytical and problem-solving techniques that can be applied in many different business contexts.

Process Mapping is one of the most fundamental skills. The ability to accurately document the steps of a process in a visual format is the starting point for almost any improvement effort. It provides clarity, helps to identify waste and bottlenecks, and ensures that the entire team has a shared understanding of how the work is actually being done. A Green Belt will learn different levels of process mapping, from high-level SIPOC diagrams to detailed, swimlane flowcharts.

Pareto Charts are another essential tool. Based on the principle that roughly 80% of the effects come from 20% of the causes, a Pareto chart is a simple bar chart that helps to prioritize problems or causes. By organizing data and displaying it visually, it allows a team to quickly identify the most significant factors and focus their efforts where they will have the greatest leverage. This is a key tool for moving from a long list of issues to a focused improvement strategy.

Root Cause Analysis tools like the Fishbone Diagram and the 5 Whys are at the heart of the Analyze phase. These tools provide a structured way to think about and investigate the underlying causes of a problem, rather than just addressing the symptoms. Mastering these techniques is what enables a Green Belt to solve problems permanently, preventing them from recurring. They are simple in concept but incredibly powerful in practice for getting to the true source of an issue.

Finally, a Green Belt will have a solid understanding of basic statistical concepts and tools. This includes the ability to calculate measures of central tendency and dispersion, create histograms to understand data distributions, and use control charts to monitor process stability. While not expected to be a master statistician like a Black Belt, a Green Belt's ability to use data to describe a process and make informed decisions is a key differentiator and a source of their value to an organization.

Becoming a Strategic Problem-Solver

One of the most significant career benefits of a Lean Six Sigma Green Belt certification is the transformation in one's approach to problem-solving. In many work environments, problem-solving is often a reactive and chaotic process, a form of "firefighting" where teams rush to apply quick fixes to the most visible symptoms. This approach rarely addresses the underlying issues, leading to recurring problems and a state of constant crisis management. The Green Belt training completely re-frames this dynamic.

The DMAIC methodology instills a structured, disciplined, and strategic approach to solving problems. A certified Green Belt learns to step back from the immediate panic, define the problem clearly, and use data to understand its true scope and impact. They are trained to resist the temptation to jump to conclusions and instead conduct a thorough analysis to identify the scientifically validated root causes. This methodical process ensures that the solutions implemented are not just temporary patches but are effective and sustainable.

This ability to systematically dissect a complex business problem and develop a robust, data-backed solution is an incredibly valuable and transferable skill. It demonstrates a level of critical thinking and analytical rigor that is highly sought after by employers. A Green Belt is no longer just an employee who reports problems; they become a valuable asset who can be trusted to lead a team to solve them. This capability is a clear differentiator and a key driver for career advancement.

As a Green Belt successfully completes projects, they build a reputation as a strategic thinker and an effective change agent. They are seen as individuals who can bring order to chaos, make sense of complex situations, and deliver measurable results. This reputation often leads to greater responsibilities, more challenging assignments, and a faster trajectory into leadership roles. The problem-solving skills learned are not confined to formal LSS projects; they become an integral part of how a professional approaches all aspects of their work.

Enhancing Your Data Analysis Skills

In the modern economy, data is one of the most valuable assets an organization possesses. The ability to collect, analyze, and interpret data to make informed decisions is no longer a niche skill but a core competency required in almost every professional field. A Lean Six Sigma Green Belt certification provides a practical and applied education in data analysis that is directly relevant to business improvement.

The training moves a professional beyond relying on intuition or "gut feelings" and teaches them how to use data to uncover insights and drive decisions. A Green Belt learns the fundamentals of statistics, not in an abstract, academic way, but in the context of solving real-world problems. They learn how to design a data collection plan, how to ensure data integrity through measurement system analysis, and how to use descriptive statistics to summarize and communicate the characteristics of a process.

Green Belts become proficient in using a variety of graphical analysis tools to visualize data and identify patterns. They learn to create and interpret histograms to understand the distribution of their data, run charts to see how a process performs over time, and scatter plots to investigate the relationship between different variables. These visual tools are incredibly powerful for making complex data understandable and for communicating findings to a non-technical audience.

While a Green Belt is not expected to have the deep statistical expertise of a Black Belt, they do gain a solid foundation that allows them to participate intelligently in data-driven conversations and projects. This "data literacy" is a massive advantage in the workplace. It enables them to ask better questions, challenge assumptions with facts, and contribute to a culture where decisions are based on evidence rather than opinion. This skill set is in high demand and directly contributes to a professional's marketability and career growth.

Developing Project Management Expertise

Every Lean Six Sigma DMAIC project is, in essence, a well-defined project with a clear start, end, and set of deliverables. As a result, leading a Green Belt project is an excellent way to develop and demonstrate core project management skills. The training and practical application of the DMAIC framework provide hands-on experience in managing a project from conception through to completion, a skill set that is valuable in any role.

The Define phase of DMAIC is directly analogous to the initiation and planning phases of traditional project management. A Green Belt learns how to create a Project Charter, which involves defining the project's scope, objectives, and stakeholders. They learn how to set realistic goals and timelines, and how to get buy-in and approval from leadership to proceed. This is the foundation of any successful project, ensuring that there is clarity and alignment from the very beginning.

Throughout the project, the Green Belt is responsible for managing the project team, facilitating meetings, and keeping the project on track. They learn how to assign tasks, monitor progress against the project plan, and manage the team's dynamics. They also learn how to manage risks, as they proactively identify potential barriers to success and develop mitigation plans. These are all fundamental skills that are taught in formal project management training, but a Green Belt gets to learn and apply them in the context of delivering a tangible business improvement.

Successfully completing a Green Belt project is a powerful accomplishment to add to a resume. It serves as concrete proof of one's ability to manage a project, lead a team, and deliver measurable results. Many organizations view Green Belt certification as a stepping stone to more formal project management roles. The practical experience gained is often more valuable to employers than purely theoretical knowledge, making it a significant catalyst for career advancement.

Gaining Leadership and Teamwork Abilities

Leading a process improvement project is not just a technical exercise; it is a significant leadership challenge. A Green Belt project leader is tasked with guiding a team of their peers, who are often subject matter experts in the process being improved. This requires a strong set of leadership, facilitation, and interpersonal skills. The experience of leading a Green Belt project is therefore a fantastic opportunity for professionals to develop these crucial "soft skills."

A Green Belt must be able to motivate the project team and keep them engaged throughout the DMAIC process. They learn how to facilitate productive brainstorming sessions, how to manage disagreements and build consensus, and how to ensure that every team member feels heard and valued. They are not expected to be the expert in the process itself but rather the expert in the improvement methodology, guiding the team and harnessing their collective knowledge.

This experience builds confidence and credibility. As a Green Belt successfully leads a team to a positive outcome, they demonstrate their ability to influence others without necessarily having formal authority over them. This is a hallmark of effective leadership and is a quality that senior managers look for when identifying future leaders within the organization. The project provides a safe and structured environment to practice and hone these leadership skills.

Furthermore, a Green Belt learns the importance of teamwork and collaboration. They understand that the best solutions are developed when diverse perspectives are brought together. They learn how to leverage the strengths of each team member and how to foster a collaborative environment where the team is more effective than the sum of its individual parts. These teamwork and leadership skills are universally applicable and are a major benefit of the Green Belt journey, contributing significantly to a professional's overall effectiveness and promotability.

Improving Communication and Stakeholder Management

A key component of any successful project is effective communication. A Lean Six Sigma Green Belt must be able to communicate clearly and persuasively with a wide variety of audiences, from the frontline staff working in the process to the senior executives who are sponsoring the project. The Green Belt training and project experience provide ample opportunity to develop these critical communication skills.

Throughout a project, the Green Belt is responsible for providing regular status updates to stakeholders. They learn how to distill complex information into a clear and concise message, using data and visual charts to tell a compelling story about the project's progress. They must be able to present their findings from the Analyze phase and their proposed solutions from the Improve phase in a way that is understandable and convincing, securing the buy-in needed to move forward.

This involves tailoring the communication style to the audience. When speaking with the project team, the conversation may be highly detailed and technical. When presenting to a leadership steering committee, the focus needs to be on the high-level business impact, such as the financial benefits or the improvement in customer satisfaction. A Green Belt learns how to navigate these different contexts, a skill that is vital for effective corporate communication.

Closely related to communication is stakeholder management. A Green Belt learns to identify all the individuals and groups who have an interest in or will be affected by the project. They must understand their concerns and expectations and manage them proactively throughout the project lifecycle. This involves building relationships, seeking input, and keeping stakeholders informed to prevent resistance and ensure a smooth implementation of the proposed changes. These advanced communication and stakeholder management skills are hallmarks of a mature professional and are highly valued by employers.

The Financial Impact: Salary and Promotions

While the development of valuable skills is a primary benefit, many professionals are also interested in the tangible financial impact of a Lean Six Sigma Green Belt certification. The data consistently shows that certified professionals command higher salaries than their non-certified peers. This salary premium is a direct reflection of the value that these individuals bring to an organization.

Employers are willing to pay more for certified Green Belts because they have demonstrated a clear ability to deliver measurable financial results. A Green Belt is not just an expense; they are an investment that is expected to provide a significant return. By leading projects that reduce costs, eliminate waste, improve quality, and increase customer satisfaction, a Green Belt directly contributes to the company's bottom line. Their certification serves as a credible signal to employers that they possess these value-creation skills.

The salary increase can vary depending on the industry, the individual's years of experience, and their geographical location, but it is a consistent trend. The certification makes a candidate's resume stand out in a competitive job market and often opens doors to higher-paying roles and companies that have a mature continuous improvement culture. The investment in getting certified often pays for itself many times over in the form of increased earning potential throughout one's career.

Beyond just the initial salary bump, the certification is a powerful catalyst for promotions. As a Green Belt successfully delivers projects and demonstrates their problem-solving and leadership skills, they become highly visible within their organization. They are often seen as high-potential employees who are capable of taking on greater responsibility. This can lead to a faster career progression, moving from an individual contributor role into team lead, manager, or even more senior leadership positions. The certification is not just a line on a resume; it is a proven pathway to a more rewarding and lucrative career.

Driving Tangible Cost Reductions

One of the most compelling reasons that organizations invest in Lean Six Sigma training for their employees is its proven ability to drive significant cost reductions. A certified Green Belt is trained to view every process through a lens of efficiency and to identify opportunities to eliminate waste, which directly translates into financial savings. These savings are not based on arbitrary budget cuts but are the result of making processes smarter, faster, and more reliable.

The Lean aspect of the methodology provides a direct path to cost reduction by focusing on the eight wastes. For example, a Green Belt might lead a project that redesigns a workplace layout to reduce unnecessary motion and transportation, saving both time and energy costs. They might identify and eliminate an extra-processing step, such as a redundant review or an unnecessary report, freeing up employee time to focus on value-added activities. By reducing defects and the need for rework, they also save on material and labor costs.

The Six Sigma aspect contributes to cost reduction by improving process quality and consistency. A process with high variation is often an expensive process. It may produce a significant amount of scrap or require costly inspection activities to sort the good products from the bad. By using the DMAIC methodology to identify and address the root causes of this variation, a Green Belt can make a process more capable and predictable, leading to a dramatic reduction in the costs associated with poor quality.

These cost savings are not just theoretical; they are a required outcome of any well-run Green Belt project. The Project Charter in the Define phase often includes an estimate of the expected financial benefits, and the Control phase involves validating and tracking the actual savings achieved. This focus on delivering a quantifiable return on investment is what makes the Lean Six Sigma program so appealing to senior leadership and is a key reason why certified professionals are so highly valued.

Enhancing Customer Satisfaction and Loyalty

While cost reduction is a powerful internal benefit, the ultimate goal of any successful organization is to create and retain satisfied customers. Lean Six Sigma provides a direct framework for achieving this by placing a relentless focus on quality and the customer experience. A core principle of the methodology is that quality is defined by the customer. A Green Belt project is therefore often aimed at improving the aspects of a product or service that matter most to them.

The DMAIC process begins with understanding the Voice of the Customer (VOC). By gathering and analyzing customer feedback, a Green Belt can identify the key drivers of customer satisfaction and dissatisfaction. This allows them to focus their improvement efforts on the issues that will have the biggest positive impact on the customer. For example, a project might be initiated to reduce the lead time for a service because VOC analysis shows that delivery speed is a critical customer requirement.

By reducing defects and errors, Lean Six Sigma directly improves the quality of the products and services that reach the customer. A customer who receives a defect-free product or an error-free invoice is more likely to be satisfied with their experience. This consistency and reliability build trust and confidence in the brand. A Green Belt project that reduces the error rate in a billing process, for example, not only saves the company money in rework costs but also prevents customer frustration and protects the company's reputation.

Ultimately, a better customer experience leads to increased customer loyalty and retention. Loyal customers are more likely to make repeat purchases and to recommend the company to others. By leading projects that result in higher quality, faster service, and fewer errors, a Green Belt plays a direct role in driving this loyalty. This ability to connect internal process improvement activities to the external goal of customer satisfaction is a strategic skill that makes a Green Belt a valuable asset in any customer-facing organization.

Applications in the Healthcare Sector

The misconception that Lean Six Sigma is only for manufacturing is particularly outdated when considering the healthcare sector. In fact, healthcare is one of the industries where these principles are having the most profound impact. The focus on patient safety, quality of care, and operational efficiency makes healthcare a perfect environment for the application of the Lean Six Sigma methodology. Green Belts in healthcare work on projects that can have a life-changing impact on patients and staff.

A common area of focus is improving patient flow and reducing wait times. Long waits in emergency departments, for appointments, or for test results are a major source of patient dissatisfaction and can even lead to poorer health outcomes. A Green Belt could lead a project to map the entire patient journey, identify bottlenecks, and streamline the process to ensure patients receive the care they need in a more timely manner. This improves the patient experience and allows the facility to treat more patients with the same resources.

Another critical application is in improving patient safety by reducing medical errors. A Green Belt might use the DMAIC framework to investigate the root causes of medication administration errors or hospital-acquired infections. By standardizing processes, implementing checklists, and mistake-proofing critical tasks, they can create a safer environment for patients. These projects not only prevent harm but also reduce the significant costs associated with medical errors.

The methodology is also applied to the administrative and support processes within healthcare. For example, projects can focus on improving the accuracy and speed of the medical billing process, optimizing the management of surgical supplies to reduce waste, or streamlining the patient scheduling system. By making these background processes more efficient, a Green Belt can help the organization to reduce costs and free up more resources to be dedicated to direct patient care.

Applications in the Finance and Banking Sector

The finance and banking sector is another area where Lean Six Sigma has been widely adopted. This industry is characterized by complex, high-volume transactional processes where accuracy, speed, and compliance are critically important. Green Belts in this sector work on a wide variety of projects aimed at improving operational efficiency, enhancing the customer experience, and reducing risk.

A frequent application is in the streamlining of core processes like loan application processing, new account opening, or insurance claim handling. These processes often involve multiple departments, complex decision rules, and a significant amount of paperwork. A Green Belt can use process mapping and data analysis to identify bottlenecks, eliminate redundant steps, and automate manual tasks, resulting in a dramatic reduction in the turnaround time for these services. This not only improves customer satisfaction but also increases the capacity of the organization.

Reducing errors and ensuring regulatory compliance are also top priorities in finance. An error in a financial transaction or a compliance breach can have severe financial and reputational consequences. A Green Belt can lead a project to analyze the root causes of common errors, such as data entry mistakes or incorrect calculations. By implementing improved controls, standardized work instructions, and mistake-proofing techniques, they can significantly improve the accuracy and quality of these processes, thereby reducing operational risk.

The customer service functions within the financial sector also benefit from Lean Six Sigma. A Green Belt project might focus on improving the performance of a call center by reducing call handling times while improving first-call resolution rates. By analyzing call data and customer feedback, the team can identify the most common reasons for calls and develop better solutions and training for the service agents. This leads to a more efficient call center and a less frustrating experience for the customer.

Lean Six Sigma Green Belt certification practice test questions and answers, training course, study guide are uploaded in ETE files format by real users. Study and pass Six Sigma Lean Six Sigma Green Belt certification exam dumps & practice test questions and answers are the best available resource to help students pass at the first attempt.