- Home

- Microsoft Certifications

- MB-330 Microsoft Dynamics 365 Supply Chain Management Dumps

Pass Microsoft Dynamics 365 MB-330 Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

MB-330 Premium Bundle

- Premium File 454 Questions & Answers. Last update: Feb 26, 2026

- Training Course 5 Video Lectures

Last Week Results!

Includes question types found on the actual exam such as drag and drop, simulation, type-in and fill-in-the-blank.

Based on real-life scenarios similar to those encountered in the exam, allowing you to learn by working with real equipment.

All Microsoft Dynamics 365 MB-330 certification exam dumps, study guide, training courses are Prepared by industry experts. PrepAway's ETE files povide the MB-330 Microsoft Dynamics 365 Supply Chain Management practice test questions and answers & exam dumps, study guide and training courses help you study and pass hassle-free!

Expert Guidance on Preparing for the MB-330 Dynamics SCM Exam

The MB-330 exam evaluates a candidate’s expertise in Microsoft Dynamics 365 Supply Chain Management. It focuses on assessing the ability to implement and manage supply chain processes, configure inventory and warehouse operations, handle transportation logistics, and ensure quality and compliance. Success in this exam demonstrates that a candidate can manage end-to-end supply chain operations effectively, integrating multiple functional areas and optimizing resources for operational efficiency.

Supply Chain Management Fundamentals

Supply chain management in Dynamics 365 involves coordinating the flow of goods, information, and resources across suppliers, manufacturers, warehouses, and customers. Candidates are expected to understand how to streamline processes, reduce bottlenecks, and maintain accuracy across inventory, procurement, and production operations. This includes analyzing supply chain activities, identifying inefficiencies, and implementing solutions that enhance productivity and operational visibility.

Inventory Configuration and Management

Inventory management is central to the MB-330 exam. Candidates must understand how to configure inventory dimensions, manage product variants, and set up reservation hierarchies. Proficiency includes handling inventory journals, performing adjustments, and maintaining accurate stock levels. Understanding costing methods, standard costs, and trade agreements is essential to ensure financial accuracy and operational control. Efficient inventory management ensures that products are available when needed while minimizing excess stock and associated costs.

Product Information and Master Data

Managing product information is crucial for supply chain operations. Candidates should know how to create and maintain product records, assign attributes, manage product templates, and handle product lifecycle states. Master data forms the foundation for inventory, procurement, and production processes, so understanding its structure and ensuring accuracy is vital. Knowledge of bills of materials, category hierarchies, and product dimensions supports seamless integration across modules and enables accurate reporting and planning.

Procurement and Sourcing Processes

Candidates are expected to configure and manage procurement workflows, including purchase requisitions, requests for quotations, and purchase orders. This also includes handling vendor returns, consignment inventory, and purchase agreements. Effective procurement ensures timely availability of materials, cost control, and strong vendor relationships. Understanding how to implement purchasing policies, configure procurement categories, and manage vendor collaboration is key for efficient supply chain operations.

Sales and Customer Management

Managing customer orders, sales agreements, and delivery schedules is a vital component of the exam. Candidates should know how to process sales quotations, intercompany orders, and customer rebates. Understanding available-to-promise and capable-to-promise calculations helps ensure accurate order fulfillment. Configuring sales groups, commissions, and delivery schedules supports operational efficiency and customer satisfaction while integrating seamlessly with inventory and warehouse management processes.

Warehouse Management Essentials

Warehouse management focuses on optimizing the storage and movement of goods. Candidates need to configure warehouse structures including sites, locations, zones, and storage profiles. Implementing work policies, location directives, and warehouse workers’ assignments ensures efficient operational workflows. Understanding wave, load, and work templates, along with mobile device configuration, helps streamline order picking, replenishment, and cycle counting processes. Efficient warehouse management reduces errors, improves throughput, and supports accurate inventory reporting.

Transportation Management

Transportation management involves planning and executing inbound and outbound shipments efficiently. Candidates should know how to configure carriers, shipping routes, and rate engines, as well as generate freight invoices and reconcile transportation costs. Understanding dock appointment scheduling and load planning ensures timely deliveries while reducing operational costs. Integrating transportation processes with warehouse and inventory management supports an optimized and cohesive supply chain operation.

Quality Control and Assurance

Quality management includes configuring quality orders, handling nonconformances, and monitoring production and inventory processes to maintain standards. Candidates should understand how to implement quality control workflows, process quarantine orders, and apply quality associations to materials. Ensuring compliance with quality policies minimizes defects, reduces rework, and enhances customer satisfaction while supporting operational efficiency across the supply chain.

Asset Management

Asset management involves creating and maintaining work orders, scheduling preventive and reactive maintenance, and managing functional locations. Candidates must configure assets, track utilization, and manage asset loans. Efficient asset management ensures that equipment and machinery are available when required, reducing downtime and supporting operational continuity. Integrating asset management with inventory and warehouse processes helps maintain seamless supply chain operations.

Master Planning and Forecasting

Master planning integrates supply and demand to optimize inventory levels, production schedules, and resource allocation. Candidates are expected to configure coverage groups, master planning parameters, and safety stock levels. Running master planning processes, evaluating planned orders, and analyzing supply schedules are critical for ensuring operational efficiency. Effective forecasting and planning allow organizations to anticipate demand fluctuations and adjust operations proactively, supporting consistent service levels and resource utilization.

Pricing, Costing, and Trade Management

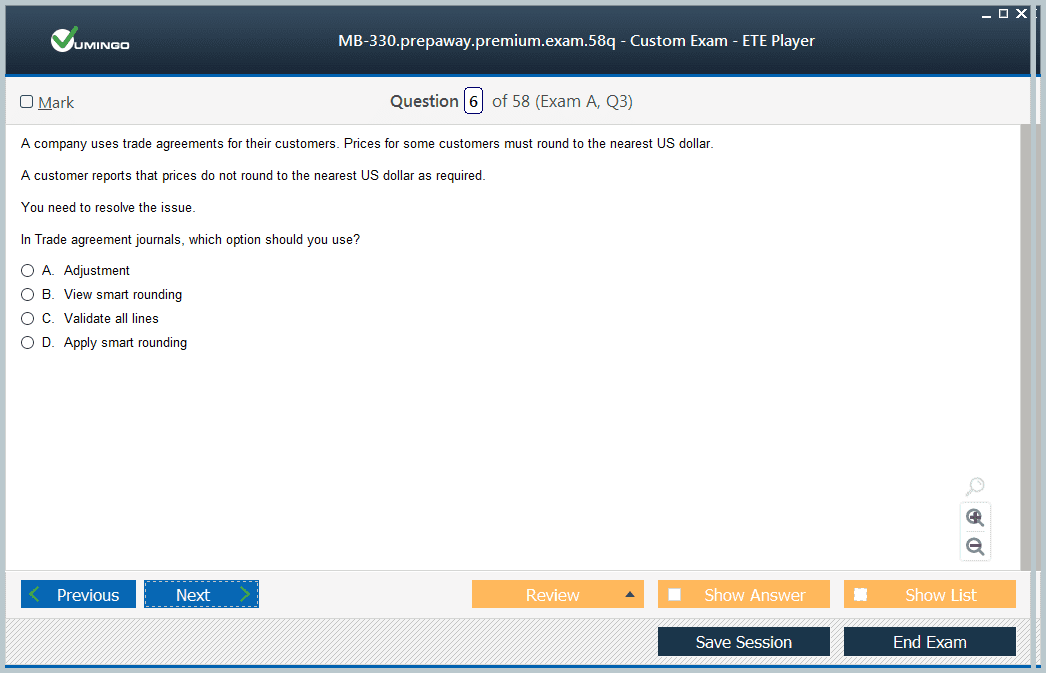

Costing and pricing management is essential for maintaining profitability within supply chain operations. Candidates should understand how to configure standard costs, maintain costing versions, and manage trade agreements. Accurate configuration of pricing, purchase costs, and sales discounts ensures financial integrity. Knowledge of commodity pricing, item price groups, and auto-cost processes supports precise reporting and informed decision-making across procurement, sales, and inventory modules.

Scenario-Based Problem Solving

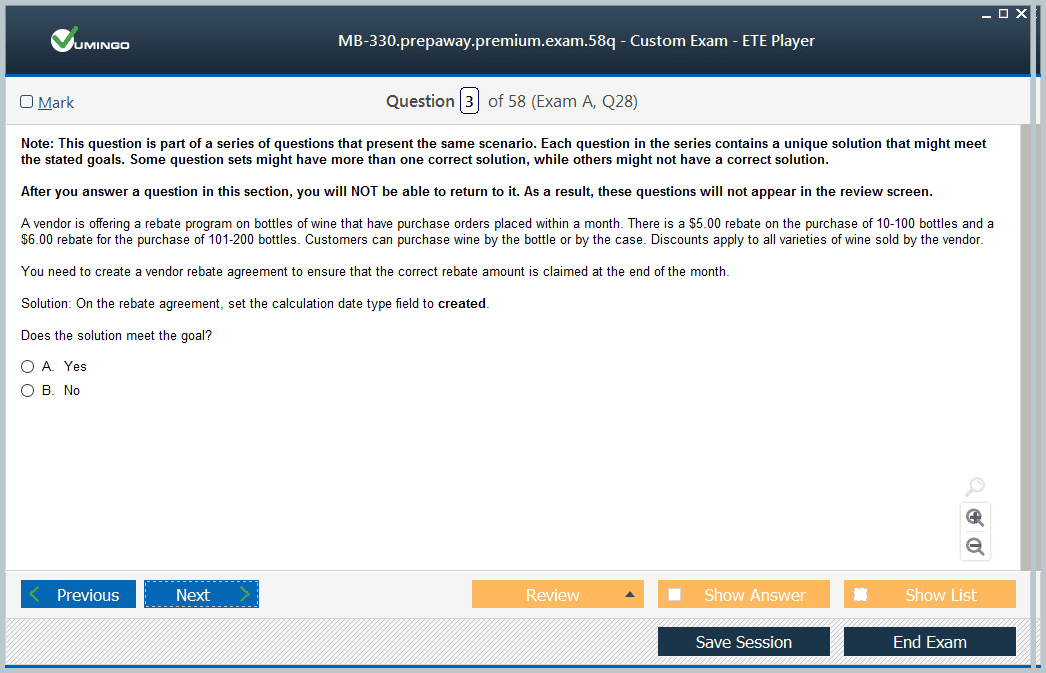

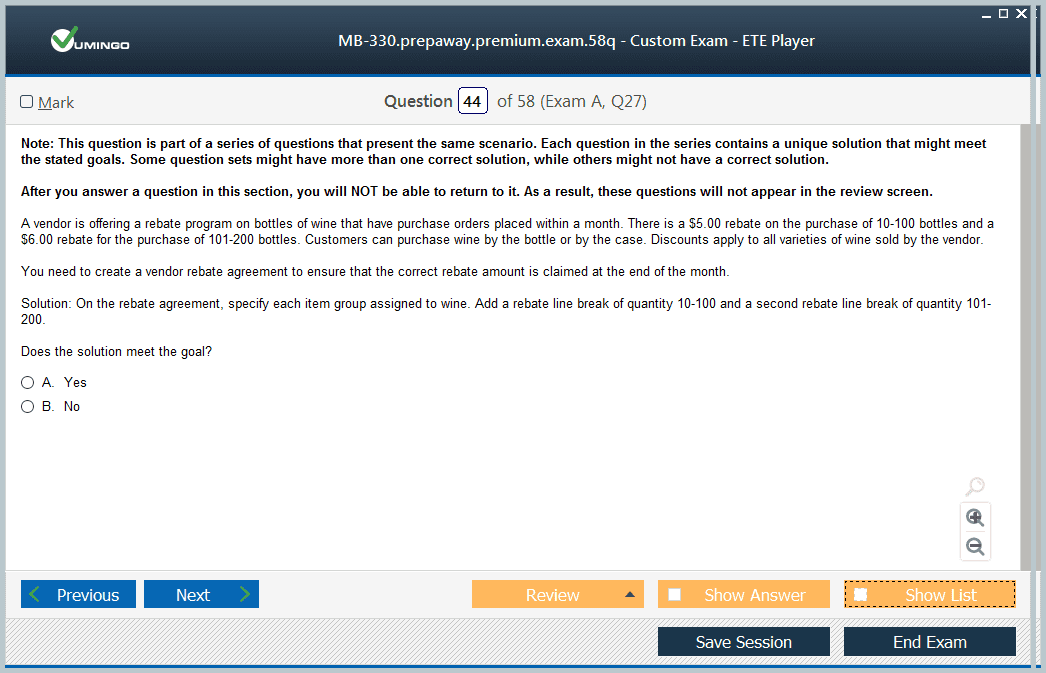

The MB-330 exam includes scenario-based questions that evaluate candidates’ ability to apply integrated knowledge across modules. Candidates should practice analyzing complex situations, identifying appropriate solutions, and executing transactions within the system. Scenarios may involve intercompany transactions, supply disruptions, or demand fluctuations. Proficiency in handling these scenarios demonstrates practical understanding and ensures readiness for real-world supply chain challenges.

Workflow Optimization

Optimizing workflows enhances operational efficiency and reduces errors. Candidates should understand how to automate approval processes, configure directives, and implement standardized procedures. Effective workflow management across procurement, inventory, warehouse, and transportation operations improves productivity and supports consistent compliance with organizational policies. Continuous evaluation and improvement of workflows help maintain efficiency and adaptability within dynamic supply chain environments.

Analytical and Reporting Skills

Analytical capabilities are critical for interpreting supply chain data, monitoring performance, and supporting decision-making. Candidates should be able to generate reports on inventory levels, production schedules, procurement activities, and transportation metrics. Using these insights allows for identifying trends, forecasting demand, and optimizing resources. Strong reporting skills also enable compliance verification and highlight areas for operational improvement, contributing to overall supply chain effectiveness.

Hands-On Experience

Practical experience with Dynamics 365 Supply Chain Management reinforces theoretical knowledge. Candidates should perform exercises such as configuring warehouses, managing purchase orders, processing inventory journals, and executing transportation plans. Hands-on practice familiarizes candidates with system functionality, improves efficiency, and enhances confidence in applying knowledge to both exam scenarios and real-world tasks.

Collaboration and Knowledge Sharing

Engaging with peers and professional communities provides exposure to diverse challenges and best practices. Discussion forums allow candidates to clarify doubts, share solutions, and learn alternative approaches to common supply chain problems. Collaborative learning supports deeper understanding, reinforces key concepts, and provides motivation throughout exam preparation, ensuring well-rounded competence in supply chain management.

Practice and Simulation

Simulated exercises and practice tests are essential for evaluating readiness. These activities help candidates familiarize themselves with exam format, timing, and question types. Identifying strengths and weaknesses through practice allows for focused study and skill improvement. Regular simulation reduces exam anxiety, builds confidence, and develops proficiency in applying knowledge under exam conditions.

Continuous Learning and Adaptability

Supply chain management is dynamic, requiring ongoing learning and adaptation. Candidates should focus on understanding system updates, process improvements, and emerging operational strategies. Cultivating a mindset of continuous improvement ensures long-term proficiency, operational agility, and sustained professional growth within supply chain roles.

Integrated Knowledge Across Modules

Candidates must demonstrate the ability to integrate knowledge across inventory, procurement, sales, warehouse, and transportation modules. Understanding how changes in one area affect others is essential for operational efficiency. This includes analyzing dependencies, tracing transactions, and applying corrections. Integrated knowledge ensures seamless operations, accurate reporting, and effective decision-making.

Advanced Planning and Resource Allocation

Effective planning and resource allocation optimize operational performance. Candidates should manage production schedules, balance inventory levels, and forecast demand accurately. Mastering safety stock, coverage settings, and master planning parameters ensures the organization can meet customer demand while minimizing costs and resource waste. Advanced planning skills also support proactive decision-making and operational responsiveness.

Decision-Making and Problem-Solving

Strong decision-making skills are necessary to handle scenario-based challenges. Candidates must evaluate multiple solutions, consider operational constraints, and implement effective strategies. Analytical thinking supports efficient problem resolution, resource allocation, and workflow optimization. Demonstrating these skills in practice and simulations prepares candidates for complex exam scenarios and real-world supply chain management tasks.

System Configuration and Optimization

Candidates need proficiency in configuring system settings to optimize supply chain operations. This includes configuring warehouses, inventory parameters, procurement workflows, transportation plans, and quality control processes. Proper configuration ensures accuracy, efficiency, and compliance across all operational areas. Optimized system settings also reduce manual effort, minimize errors, and support seamless process execution.

Exam Preparation Strategies

A structured approach to exam preparation enhances readiness. Candidates should combine theoretical study, hands-on exercises, and scenario-based practice. Breaking preparation into stages—starting with core concepts and progressing to integrated scenarios—ensures comprehensive coverage. Identifying key focus areas, tracking progress, and adjusting study strategies maintain efficiency and motivation.

Practical Scenarios and Real-World Application

Practicing real-world scenarios prepares candidates for both the exam and professional responsibilities. This includes handling supply chain disruptions, processing intercompany transactions, and managing demand fluctuations. Understanding how to implement solutions using system functionalities demonstrates operational proficiency and readiness to manage complex supply chain operations.

Performance Monitoring and Continuous Improvement

Evaluating performance during preparation allows candidates to identify gaps and refine skills. Regular self-assessment, review of practice exercises, and focused improvement ensure mastery of all exam topics. Continuous improvement also builds confidence and ensures sustained readiness for handling integrated supply chain processes effectively.

Transportation and Logistics Integration

Candidates should understand how transportation management integrates with warehouse and inventory functions. Coordinating shipments, optimizing routes, and managing freight costs ensures smooth delivery operations. Knowledge of load planning, dock scheduling, and route optimization contributes to cost reduction, timely deliveries, and improved overall efficiency within supply chain operations.

Quality and Compliance Oversight

Ensuring compliance with quality standards and operational policies is essential. Candidates must manage quality control processes, handle nonconformances, and apply quality associations across inventory and production. Effective quality management minimizes errors, maintains customer satisfaction, and ensures operational consistency. Proficiency in these areas demonstrates attention to detail and operational competence.

Asset and Maintenance Management

Candidates are expected to manage assets and work orders efficiently. Scheduling preventive and reactive maintenance, tracking asset usage, and managing functional locations ensures operational continuity. Proper asset management reduces downtime, enhances productivity, and integrates seamlessly with inventory and warehouse processes.

Analytical Reporting and Decision Support

Strong analytical reporting supports strategic decision-making. Candidates should be able to interpret inventory levels, procurement activities, production schedules, and transportation metrics. Using insights to optimize resources, forecast demand, and plan operations enhances operational efficiency and readiness for scenario-based challenges in the exam.

Mastery of Microsoft Dynamics 365 Supply Chain Management modules requires understanding inventory, procurement, warehouse, transportation, quality, and master planning functions. Hands-on practice, scenario-based learning, and analytical skills reinforce theoretical knowledge. Integrated understanding across modules, effective workflow management, and problem-solving capabilities prepare candidates for both the MB-330 exam and professional responsibilities in managing complex supply chain operations.

Advanced Inventory Management

In-depth knowledge of inventory management is essential for the MB-330 exam. Candidates should understand how to configure advanced inventory dimensions, track inventory across multiple sites, and manage product variants efficiently. Mastery of reservation hierarchies, item model groups, and inventory costing methods ensures that stock levels are optimized and financial data is accurate. Handling journals for inventory adjustments, item arrivals, transfers, and counting helps maintain precise records and supports operational decision-making.

Product Configuration and Lifecycle

Candidates must be proficient in product configuration and lifecycle management. This includes creating products and product variants, applying templates, and managing product attributes. Understanding how to assign lifecycle states, set up unit conversions, and configure barcodes or GTIN codes ensures operational consistency and accurate tracking of products. Effective product configuration supports inventory accuracy, enhances reporting, and enables seamless integration with procurement and warehouse operations.

Procurement and Vendor Management

The exam assesses knowledge of procurement processes and vendor management. Candidates should know how to create purchase requisitions, process requests for quotations, and manage purchase orders. Configuring procurement categories, charge codes, and workflows ensures that vendor transactions are efficient and controlled. Managing vendor collaboration, consignment inventory, and vendor returns demonstrates practical understanding of procurement operations. Effective procurement management minimizes delays, optimizes costs, and strengthens supplier relationships.

Sales Order and Customer Management

Sales processes are a critical area of focus. Candidates should understand how to create and process sales quotations, orders, and returns while managing customer agreements and rebates. Knowledge of intercompany order processing, available-to-promise, and capable-to-promise functions ensures accurate fulfillment and inventory allocation. Proper handling of sales orders contributes to operational efficiency, customer satisfaction, and integrated reporting across finance and supply chain modules.

Warehouse Operations and Optimization

Candidates should be able to configure warehouse layouts, locations, zones, and location profiles to optimize operations. Understanding work policies, location directives, and warehouse worker assignments helps streamline tasks. Configuring wave, load, and work templates along with mobile device menus allows for efficient picking, replenishment, and cycle counting. Advanced warehouse processes, including containerization, packaging, and cross-docking, improve throughput, reduce errors, and ensure timely delivery.

Transportation Planning and Execution

Transportation management involves configuring carriers, shipping routes, rate engines, and freight invoices. Candidates should understand load planning, dock scheduling, and route optimization. Integrating transportation with inventory and warehouse management ensures timely and cost-effective deliveries. Knowledge of manual and automated freight reconciliation and route planning supports operational control and reduces logistic inefficiencies. Effective transportation planning enhances supply chain responsiveness and customer satisfaction.

Quality Management Integration

Quality control and assurance are integrated across supply chain operations. Candidates need to manage quality orders, nonconformance processes, and quarantine management. Applying quality associations to materials, configuring components for quality processes, and processing quality orders ensures compliance with standards. Knowledge of inventory blocking through quality management helps maintain accuracy and reduces the risk of defective products reaching customers. Quality management processes contribute to consistent production outcomes and operational reliability.

Asset Management and Maintenance

Candidates are expected to configure assets, manage work orders, and schedule preventive and reactive maintenance. Functional locations, asset loans, and capacity planning are critical components of asset management. Proper maintenance planning and execution reduce equipment downtime, ensure resource availability, and integrate with overall supply chain operations. Asset management knowledge allows candidates to optimize operational efficiency, prolong equipment lifespan, and support cost-effective production.

Master Planning and Forecast Analysis

Master planning involves coordinating supply and demand to ensure sufficient inventory while minimizing excess stock. Candidates should understand coverage groups, master planning parameters, and action messages. Running master planning, analyzing results, evaluating planned orders, and managing safety stock are key skills. Forecasting and planning ensure resource efficiency, timely production, and readiness for market fluctuations. Knowledge of time fences, delay messages, and planning periods allows for accurate scheduling and operational responsiveness.

Cost Management and Pricing Strategies

Understanding costing methods, standard costs, trade agreements, and pricing structures is vital for the MB-330 exam. Candidates should configure and maintain costing versions, item prices, purchase costs, and sales prices. Knowledge of pricing templates, cost type codes, and auto-cost calculation ensures accurate financial reporting and decision support. Effective cost management and pricing strategies support profitability, resource optimization, and competitive operations within supply chain processes.

Scenario-Based Application

The MB-330 exam evaluates the ability to apply knowledge in realistic scenarios. Candidates should practice integrated workflows, handling intercompany transactions, procurement challenges, inventory shortages, and transportation disruptions. Scenario-based exercises assess decision-making, problem-solving, and practical application of system functionalities. Proficiency in applying theory to practice ensures candidates can manage complex operations efficiently and demonstrates readiness for professional responsibilities.

Workflow Configuration and Automation

Workflow automation is critical for operational efficiency. Candidates must configure approval processes, automate directives, and implement standardized procedures across procurement, warehouse, and transportation operations. Effective workflow management reduces manual effort, minimizes errors, and supports consistent compliance with organizational policies. Automated workflows enhance productivity, streamline operations, and ensure timely execution of supply chain processes.

Reporting and Analytics

Analytical and reporting skills are essential for monitoring performance and supporting decision-making. Candidates should be able to generate reports on inventory, procurement, warehouse, sales, and transportation metrics. Using analytics, they can identify trends, forecast demand, optimize operations, and verify compliance. Strong reporting capabilities enable informed decisions, operational adjustments, and strategic planning. Analytical proficiency ensures a clear understanding of process performance and resource allocation.

Hands-On System Proficiency

Practical experience with Dynamics 365 Supply Chain Management strengthens theoretical knowledge. Candidates should configure warehouses, manage purchase orders, process inventory journals, and execute transportation plans. Hands-on practice allows for understanding system behavior, troubleshooting, and improving task efficiency. Proficiency in executing practical tasks prepares candidates for scenario-based exam questions and real-world applications.

Collaboration and Peer Learning

Engaging with peers and professional communities supports learning through shared experiences and problem-solving. Candidates can discuss challenges, exchange solutions, and observe different approaches to supply chain operations. Collaborative learning reinforces understanding, encourages knowledge retention, and maintains motivation throughout preparation. Interaction with peers develops communication skills, teamwork, and exposure to diverse operational scenarios.

Practice Testing and Simulation

Regular practice testing is important for exam readiness. Simulated exams help candidates familiarize themselves with question formats, timing, and scenario-based challenges. Practice tests identify knowledge gaps and guide targeted preparation. Repeated simulation builds confidence, reduces stress, and enhances problem-solving under timed conditions. Candidates gain insight into their readiness level and adjust study strategies accordingly.

System Integration Awareness

Understanding how various supply chain modules interact is crucial. Candidates must know the impact of inventory changes on procurement, warehouse operations, and transportation. Integrated knowledge allows for accurate execution of transactions, resource allocation, and reporting. Awareness of dependencies ensures smooth operations and prevents errors in interconnected processes, contributing to overall efficiency and reliability.

Advanced Planning Techniques

Advanced planning includes forecasting demand, managing safety stock, balancing production schedules, and coordinating transportation. Candidates should be able to adjust master plans based on demand variability, production capacity, and inventory levels. Mastery of planning techniques ensures operational flexibility, reduces costs, and maintains customer service levels. Advanced planning skills demonstrate the ability to optimize supply chain performance and handle complex operational scenarios.

Decision-Making and Analytical Thinking

Effective decision-making involves analyzing data, evaluating alternatives, and implementing optimal solutions. Candidates should practice assessing operational scenarios, identifying risks, and determining corrective actions. Analytical thinking enables accurate problem-solving, resource optimization, and workflow improvement. Developing decision-making skills ensures readiness to handle integrated supply chain challenges and scenario-based exam questions.

Continuous Improvement and Learning

Candidates should embrace continuous learning to maintain proficiency in system updates, process improvements, and best practices. Adapting to evolving operational strategies and new functionalities ensures long-term expertise. Continuous improvement reinforces skill retention, operational efficiency, and professional growth. Candidates who cultivate adaptability and ongoing learning are better prepared for complex tasks in both the exam and real-world environments.

Operational Efficiency and Resource Management

Managing resources effectively involves coordinating inventory, warehouse operations, transportation, and procurement processes. Candidates should understand capacity planning, load balancing, and resource allocation. Optimizing resource utilization improves throughput, reduces costs, and maintains operational continuity. Proficiency in resource management demonstrates the ability to oversee complex supply chain operations efficiently.

Scenario Analysis and Problem Resolution

Practical exercises involving real-world scenarios strengthen candidates’ problem-solving skills. Handling inventory discrepancies, procurement delays, transportation issues, and intercompany transactions requires analytical thinking and process knowledge. Candidates learn to apply system configurations, workflows, and reporting tools to resolve operational challenges effectively. Scenario analysis prepares candidates for exam simulations and professional responsibilities.

Transportation and Logistics Coordination

Coordinating transportation and logistics ensures timely and cost-effective delivery of goods. Candidates should manage carrier assignments, shipping schedules, freight invoicing, and route optimization. Integrating logistics with warehouse and inventory functions enhances operational performance and customer satisfaction. Knowledge of transportation parameters, scheduling, and planning contributes to overall supply chain reliability.

Quality Assurance and Compliance Monitoring

Ensuring product quality and compliance involves configuring quality orders, managing nonconformance processes, and applying inspection protocols. Candidates must understand how to enforce quality standards across inventory, production, and warehouse operations. Effective quality management reduces errors, supports regulatory compliance, and enhances operational reliability. Consistent monitoring and corrective actions ensure adherence to organizational policies and standards.

Asset Tracking and Maintenance Planning

Tracking assets and scheduling maintenance ensures operational continuity. Candidates should manage work orders, preventive maintenance schedules, and asset utilization. Integration with inventory and warehouse processes allows for accurate resource planning. Efficient asset management reduces downtime, improves productivity, and supports operational effectiveness across supply chain processes.

Performance Evaluation and Reporting

Monitoring operational performance through reporting allows candidates to make informed decisions. Generating reports on inventory, procurement, production, and transportation metrics enables trend analysis and performance assessment. Evaluating results and applying corrective actions ensures process optimization and operational efficiency. Strong reporting skills also support strategic planning and compliance verification.

System Configuration and Workflow Optimization

Candidates must be capable of configuring system parameters, workflows, and operational processes to ensure seamless supply chain management. Configuring warehouses, inventory dimensions, procurement workflows, and transportation plans enhances efficiency and accuracy. Optimized workflows reduce manual effort, minimize errors, and support timely execution of supply chain operations.

Master Planning Execution and Analysis

Running master planning processes, evaluating planned orders, and managing coverage groups are critical skills. Candidates should understand how to configure safety stock, action messages, and planning parameters. Proper execution and analysis of master plans ensure resources are allocated efficiently, production schedules are met, and inventory levels are optimized. Master planning supports operational continuity and responsiveness to demand changes.

Cost Control and Trade Agreements

Candidates need to manage costing, standard costs, and pricing strategies effectively. Configuring trade agreements, price groups, and cost type codes ensures financial accuracy and profitability. Understanding pricing mechanisms, cost calculations, and auto-cost processes allows candidates to maintain operational efficiency while supporting decision-making. Cost control is essential for maintaining margins and optimizing supply chain performance.

Exam Simulation and Practical Assessment

Simulated exercises provide insight into the exam format and scenario-based questions. Candidates practice integrated processes, decision-making, and problem-solving in a controlled environment. Regular simulation builds confidence, reduces anxiety, and ensures readiness for real exam conditions. Practicing realistic supply chain scenarios enhances understanding of system functionality and operational application.

Professional Competence and Application

Achieving expertise in Microsoft Dynamics Supply Chain Management demonstrates the ability to manage complex operations. Candidates gain proficiency in inventory, procurement, warehouse, transportation, quality, and master planning processes. Applied knowledge ensures operational efficiency, accurate reporting, and effective resource utilization. Mastery of these areas prepares candidates for professional responsibilities and operational decision-making.

Integrated Supply Chain Knowledge

The exam emphasizes understanding how modules interact across the supply chain. Candidates must analyze dependencies, assess operational impacts, and implement changes accurately. Integrated knowledge ensures seamless execution of processes, reduces errors, and enhances performance. Candidates capable of managing interconnected functions are prepared for advanced operational challenges and scenario-based exam questions.

Comprehensive preparation for the MB-330 exam involves advanced knowledge of inventory, procurement, warehouse, transportation, quality, and master planning functions. Candidates benefit from hands-on practice, scenario-based problem-solving, and analytical reporting. Understanding system configurations, workflow optimization, and integrated supply chain processes ensures operational efficiency. Mastery of these concepts prepares candidates for both exam success and professional responsibilities in managing complex supply chain operations effectively

Comprehensive Understanding of MB-330 Exam

The MB-330 exam evaluates a professional's ability to implement and manage advanced supply chain operations using Microsoft Dynamics 365. Candidates are expected to demonstrate expertise across multiple functional areas, including inventory, procurement, warehouse, transportation, quality management, asset maintenance, master planning, and integrated reporting. Achieving proficiency in these areas ensures that supply chain processes are optimized, cost-effective, and aligned with organizational objectives.

Advanced Product Management

In-depth knowledge of product management is essential. Candidates should be able to configure products and variants, create product templates, and manage product attributes efficiently. Understanding lifecycle management, product states, and category hierarchies allows for accurate tracking and reporting. Proper product configuration supports inventory management, procurement processes, and warehouse operations, ensuring operational consistency and seamless integration across supply chain modules.

Inventory Optimization Techniques

Candidates must be able to implement advanced inventory control strategies. This includes configuring inventory dimensions, managing reservations, setting up item model groups, and handling multiple warehouse locations. Effective inventory management ensures accurate stock levels, reduces excess inventory, and supports timely order fulfillment. Proficiency in cost management, trade agreements, and inventory journals helps maintain financial accuracy and operational control.

Procurement and Vendor Collaboration

Managing procurement and vendor relationships is a key component of the exam. Candidates should configure procurement workflows, create purchase requisitions, manage purchase orders, and handle vendor returns. Knowledge of consignment inventory, purchase agreements, charge codes, and vendor collaboration enhances procurement efficiency. Effective procurement ensures timely availability of materials, cost optimization, and reliable supplier engagement.

Sales and Customer Operations

Understanding sales processes is critical for ensuring end-to-end supply chain efficiency. Candidates should be able to create and manage sales quotations, orders, returns, and intercompany transactions. Configuring customer agreements, rebates, and delivery schedules ensures accurate order fulfillment. Proficiency in available-to-promise and capable-to-promise calculations supports operational planning and improves customer satisfaction while integrating with inventory and warehouse management.

Advanced Warehouse Management

Warehouse operations require meticulous configuration and optimization. Candidates should manage warehouse layouts, locations, zones, location profiles, and work policies. Implementing directives, mobile device menus, and wave, load, and work templates supports efficient picking, replenishment, and cycle counting. Advanced processes, such as containerization, cross-docking, and packaging configurations, enhance throughput, reduce errors, and ensure timely order processing.

Transportation and Logistics Integration

Candidates must demonstrate knowledge of transportation planning, load management, route optimization, and carrier configuration. Executing shipments, managing dock schedules, and reconciling freight costs ensure operational efficiency. Integrating transportation management with warehouse and inventory modules allows for coordinated logistics, timely deliveries, and reduced costs. Effective transportation planning supports overall supply chain performance and reliability.

Quality Management Implementation

Ensuring consistent quality across products and processes is vital. Candidates should configure quality orders, manage nonconformance processes, and handle quarantine orders. Knowledge of quality associations, inspection protocols, and inventory blocking ensures compliance with organizational standards. Quality management minimizes defects, supports regulatory compliance, and enhances operational reliability throughout the supply chain.

Asset Management and Maintenance Planning

Candidates are expected to configure and maintain assets, schedule preventive and reactive maintenance, and manage work orders efficiently. Understanding functional locations, asset loans, and capacity planning ensures optimal resource utilization. Proper asset management reduces downtime, increases productivity, and integrates seamlessly with warehouse and inventory operations. Efficient management of assets contributes to the overall effectiveness of supply chain processes.

Master Planning and Forecasting

Master planning integrates supply and demand to optimize inventory, production schedules, and resource allocation. Candidates must configure coverage groups, master planning parameters, and safety stock levels. Running master planning processes, analyzing results, evaluating planned orders, and managing supply schedules ensures operational readiness and cost efficiency. Accurate forecasting and planning allow organizations to meet customer demand while minimizing resource waste.

Cost Management and Pricing Strategies

Proficiency in cost management and pricing is critical. Candidates should configure standard costs, maintain costing versions, and manage trade agreements. Accurate pricing, purchase costs, and sales prices support financial integrity and informed decision-making. Understanding commodity pricing, item price groups, and auto-cost processes ensures operational efficiency and supports organizational profitability across the supply chain.

Scenario-Based Problem Solving

The exam includes complex scenarios requiring integrated knowledge. Candidates should practice evaluating multi-module situations, resolving procurement or inventory issues, and handling intercompany transactions. Scenario-based problem solving tests the ability to apply theoretical knowledge practically. Mastery of such scenarios demonstrates readiness for both professional responsibilities and the exam's situational questions.

Workflow Automation and Optimization

Optimizing workflows is essential for operational efficiency. Candidates must configure approval processes, automate directives, and implement standardized procedures across procurement, warehouse, and transportation operations. Automated workflows reduce manual effort, minimize errors, and support consistent compliance with policies. Streamlined workflows enhance productivity and ensure timely execution of supply chain processes.

Reporting and Analytical Skills

Strong analytical skills are necessary for interpreting supply chain data and supporting decision-making. Candidates should generate reports on inventory levels, procurement activities, production schedules, and transportation performance. Analytical reporting enables trend identification, demand forecasting, and resource optimization. Effective reporting skills provide insights for operational improvements, strategic planning, and compliance verification.

Hands-On Practice and System Proficiency

Practical experience with Dynamics 365 Supply Chain Management reinforces theoretical understanding. Candidates should configure warehouses, manage purchase orders, process inventory journals, and execute transportation plans. Hands-on exercises develop familiarity with system functionalities, improve operational efficiency, and build confidence in applying knowledge to exam scenarios and real-world situations.

Peer Learning and Collaboration

Engaging with professional communities enhances learning through shared experiences and problem-solving discussions. Candidates can exchange knowledge, observe diverse approaches, and gain insights into best practices. Collaborative learning strengthens comprehension, motivates continued preparation, and develops teamwork skills relevant to supply chain management.

Practice Tests and Simulation

Practice tests are crucial for assessing readiness and improving exam performance. Simulated tests familiarize candidates with question formats, timing, and integrated scenarios. Identifying strengths and weaknesses through repeated practice enables focused preparation. Simulation builds confidence, reduces exam anxiety, and ensures candidates are prepared to tackle scenario-based questions effectively.

Integration Across Supply Chain Modules

Understanding how inventory, procurement, warehouse, transportation, quality, and master planning modules interact is vital. Candidates must analyze dependencies, implement changes accurately, and assess operational impacts. Integrated knowledge ensures seamless execution of processes, reduces errors, and supports optimal performance. Mastery of interconnected modules is essential for managing complex supply chain operations and succeeding in the exam.

Advanced Planning and Resource Allocation

Candidates should be adept at balancing production schedules, safety stock levels, and inventory requirements. Knowledge of master planning parameters, coverage groups, and action messages ensures effective resource allocation. Optimizing production and inventory resources improves operational efficiency, reduces costs, and maintains service levels. Advanced planning skills demonstrate readiness to manage complex supply chain challenges.

Decision-Making and Problem-Solving Skills

Effective decision-making involves evaluating multiple options, considering constraints, and implementing optimal solutions. Candidates should practice analyzing operational scenarios, identifying risks, and applying corrective actions. Strong problem-solving capabilities ensure accurate resource allocation, workflow optimization, and operational continuity. These skills are critical for both the exam and real-world supply chain management tasks.

Continuous Learning and Adaptability

Supply chain management evolves rapidly, requiring ongoing learning and adaptation. Candidates should focus on system updates, new functionalities, and evolving operational strategies. Developing a mindset of continuous improvement ensures long-term proficiency, operational flexibility, and professional growth. Adapting to changes enhances the ability to manage dynamic supply chain environments effectively.

Operational Efficiency and Performance Monitoring

Candidates must be able to monitor performance metrics across inventory, procurement, warehouse, and transportation processes. Evaluating data, identifying inefficiencies, and implementing improvements ensures optimized operations. Effective performance monitoring supports timely decision-making, resource allocation, and achievement of organizational objectives. Continuous assessment and refinement of processes maintain operational excellence.

Transportation and Logistics Management

Coordinating transportation operations involves planning shipments, managing freight costs, optimizing routes, and scheduling deliveries. Candidates should understand integration with inventory and warehouse management to ensure timely and cost-effective logistics. Knowledge of load planning, dock appointments, and carrier configuration enhances efficiency, reduces delays, and improves service levels.

Quality Assurance and Compliance

Ensuring compliance with quality standards involves managing quality orders, nonconformance processes, and inspection protocols. Candidates should be able to enforce quality standards across inventory, production, and warehouse operations. Maintaining consistent quality reduces errors, minimizes risk, and ensures operational reliability. Compliance monitoring is essential for maintaining customer satisfaction and organizational integrity.

Asset Management and Work Order Coordination

Candidates should manage assets effectively, including scheduling maintenance, tracking usage, and managing functional locations. Integrating asset management with warehouse and inventory operations ensures continuity and efficiency. Proper handling of work orders, preventive maintenance, and asset utilization enhances productivity and reduces operational disruptions.

Analytical Reporting for Decision Support

Reporting skills are vital for interpreting supply chain performance and making informed decisions. Candidates should be able to generate reports on inventory, procurement, warehouse operations, and transportation metrics. Analytical reporting allows for trend analysis, demand forecasting, resource optimization, and operational improvements. Data-driven decisions enhance efficiency and effectiveness across all supply chain functions.

System Configuration and Operational Optimization

Candidates must configure system settings to streamline supply chain operations. This includes configuring warehouses, inventory dimensions, procurement workflows, transportation plans, and quality management processes. Optimized configurations reduce manual effort, improve accuracy, and enhance overall operational efficiency. Proper system configuration supports seamless integration and workflow execution across supply chain modules.

Master Planning and Forecast Management

Running master planning processes, evaluating planned orders, and configuring safety stock levels are essential skills. Candidates should manage coverage groups, action messages, and planning parameters effectively. Accurate master planning ensures timely production, optimized inventory, and effective resource utilization. Understanding forecast management allows for proactive decision-making and operational flexibility.

Cost Control and Financial Management

Proficiency in managing costs, trade agreements, and pricing strategies is crucial. Candidates should configure standard costs, maintain costing versions, and set up trade agreements. Accurate financial management ensures profitability, cost control, and informed decision-making. Knowledge of pricing, purchase costs, and sales agreements supports operational efficiency and organizational goals.

Simulation Exercises and Scenario Practice

Engaging in simulated scenarios prepares candidates for exam conditions. Practice tests and scenario exercises allow candidates to apply integrated knowledge, make decisions under time constraints, and solve complex supply chain challenges. Simulation improves readiness, builds confidence, and reinforces the practical application of system functionalities.

Professional Readiness and Competence

Mastery of Microsoft Dynamics 365 Supply Chain Management ensures candidates can manage complex operations effectively. Proficiency in inventory, procurement, warehouse, transportation, quality, and master planning functions demonstrates operational competence. Applied knowledge supports decision-making, resource optimization, and efficiency across supply chain operations.

Integrated Process Management

Candidates must understand how changes in one module affect others and be able to manage interconnected processes seamlessly. Integrated process management reduces errors, enhances operational performance, and ensures accurate reporting. Mastery of interdependent functions is essential for achieving efficiency and effectiveness in supply chain operations and for success in the MB-330 exam.

Comprehensive mastery of Microsoft Dynamics 365 Supply Chain Management requires understanding advanced inventory management, procurement, warehouse, transportation, quality, asset, and master planning processes. Hands-on practice, scenario-based problem solving, workflow optimization, reporting, and integrated knowledge across modules are critical. Proficiency in these areas ensures operational efficiency, decision-making capability, and readiness for the MB-330 exam and professional supply chain management roles

Advanced Procurement Strategies

A deep understanding of procurement processes is critical for the MB-330 exam. Candidates must be able to design and manage complex procurement workflows, ensuring seamless integration with inventory, finance, and warehouse modules. This involves creating and maintaining purchase requisitions, purchase orders, requests for quotations, and purchase agreements. Mastery of consignment inventory, vendor collaboration features, and vendor returns is essential to manage supplier relationships efficiently and maintain a steady supply of materials. Efficient procurement processes reduce costs, minimize delays, and strengthen the overall supply chain.

Integrated Vendor and Customer Management

Vendor and customer management requires a comprehensive approach to ensure that supply chain operations run smoothly. Candidates should be able to configure vendor agreements, rebates, and procurement policies while also managing customer sales agreements, quotations, and returns. Understanding intercompany transactions, available-to-promise, and capable-to-promise functionality ensures accurate allocation of resources and timely fulfillment of orders. Integrated vendor and customer management improves communication, enhances operational accuracy, and ensures consistent service levels across the supply chain.

Warehouse Operations and Mobile Device Integration

Warehouse management is a critical focus area for the MB-330 exam. Candidates need to configure warehouses, sites, zones, locations, location formats, and profiles to maximize operational efficiency. Work policies, location directives, wave and load templates, and mobile device menus must be effectively managed for optimized picking, replenishment, and cycle counting. Advanced processes, including containerization, cross-docking, and label printing, are key for maintaining accuracy and throughput. Integrating mobile devices with warehouse operations ensures real-time data updates and smooth coordination between warehouse personnel and system processes.

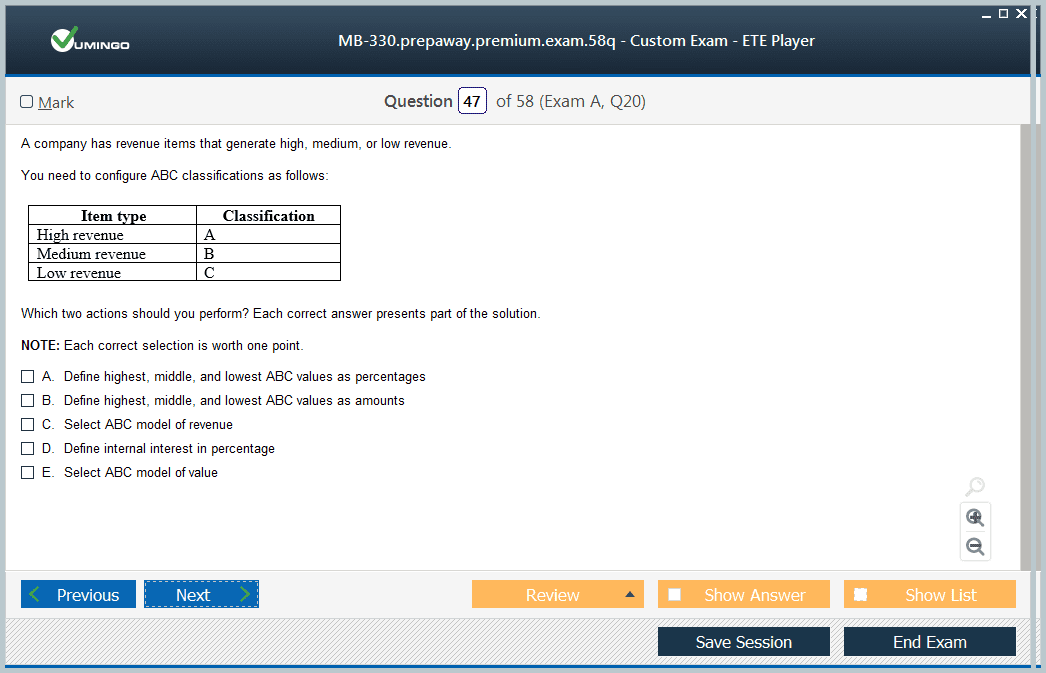

Inventory Control and Stock Optimization

Candidates should demonstrate advanced skills in inventory management, including configuring inventory dimensions, managing reservation hierarchies, item model groups, and handling inventory journals for adjustments, transfers, and counting. Knowledge of ABC classifications, inventory closing processes, and inventory blocking procedures supports accurate stock management. Inventory optimization reduces carrying costs, prevents stockouts, and aligns inventory levels with demand forecasts. Mastery of these functions ensures accurate reporting and efficient resource utilization across the supply chain.

Transportation Planning and Execution

Transportation management requires detailed knowledge of shipping carriers, carrier groups, route planning, load planning, freight invoicing, and dock scheduling. Candidates should be able to configure and manage transportation parameters, execute shipments, and reconcile freight costs accurately. Effective transportation planning ensures timely deliveries, reduces logistical errors, and integrates seamlessly with warehouse and inventory processes. This capability enhances supply chain reliability and improves overall customer satisfaction.

Master Planning and Forecast Integration

Master planning involves setting up coverage groups, item coverage, planning parameters, and safety stock levels to balance supply and demand effectively. Candidates must be able to run master planning, analyze results, evaluate planned purchase and transfer orders, and manage supply schedules. Integrating master planning with forecasting ensures that inventory, production schedules, and procurement processes are synchronized. Accurate master planning improves resource utilization, reduces production delays, and maintains service levels under varying demand conditions.

Quality Management and Compliance

Understanding quality control and assurance is essential for maintaining product standards across the supply chain. Candidates should configure quality orders, nonconformance processes, quality associations, and quarantine procedures. Applying quality management protocols to inventory, production, and warehouse operations ensures compliance with organizational and regulatory standards. Effective quality management minimizes defects, reduces operational risks, and enhances customer satisfaction by ensuring consistent product quality.

Asset Management and Maintenance

Candidates must be proficient in managing assets, including creating and configuring assets, scheduling preventive and reactive maintenance, managing work orders, and monitoring asset capacity. Functional locations, asset loans, and maintenance plans must be coordinated to ensure continuous operational efficiency. Proper asset management reduces equipment downtime, supports timely production, and optimizes resource allocation. Integrating asset management with supply chain operations ensures alignment with inventory and production processes.

Product Lifecycle and Configuration Management

Candidates should demonstrate expertise in configuring products, product variants, product templates, and product attributes. Understanding product lifecycle management, product states, and category hierarchies is critical for maintaining accurate records and operational consistency. Assigning barcodes, GTIN codes, and unit conversions supports effective inventory tracking and reporting. Mastery of product configuration ensures that all supply chain processes, from procurement to warehousing and sales, are accurately aligned.

Costing and Financial Integration

Cost management is a vital component of the MB-330 exam. Candidates must configure standard costs, maintain costing versions, and manage pricing structures for items. Knowledge of trade agreements, price groups, and auto-cost calculations ensures accurate financial reporting and operational efficiency. Effective cost management supports profitability, enables informed decision-making, and integrates with inventory and procurement processes to optimize resource allocation across the supply chain.

Scenario-Based Operational Application

The exam evaluates the ability to apply knowledge in practical scenarios. Candidates should practice integrated workflows involving inventory shortages, procurement delays, transportation disruptions, and intercompany transactions. Scenario-based exercises enhance problem-solving, decision-making, and system configuration skills. Applying theory to practice demonstrates operational readiness and prepares candidates for handling real-world supply chain challenges effectively.

Workflow Automation and Efficiency

Optimizing workflows reduces manual effort and ensures consistency across supply chain operations. Candidates should be able to configure approval processes, automate directives, and implement standardized procedures in procurement, warehouse, and transportation management. Automated workflows streamline operations, reduce errors, and maintain compliance with organizational policies. Workflow efficiency is critical for improving productivity, achieving timely execution of tasks, and supporting operational accuracy.

Reporting, Analytics, and Decision Support

Analytical skills are essential for interpreting supply chain performance data. Candidates should generate and analyze reports on inventory, procurement, warehouse, sales, and transportation activities. Understanding trends, evaluating KPIs, and forecasting demand enables informed decision-making. Effective use of reporting and analytics improves operational performance, resource planning, and supports strategic supply chain initiatives. Proficiency in these skills ensures accurate monitoring and optimization of processes.

Hands-On System Expertise

Practical experience with Microsoft Dynamics 365 Supply Chain Management enhances theoretical understanding. Candidates should perform system configurations, execute inventory transactions, manage procurement and sales orders, and coordinate warehouse and transportation processes. Hands-on practice strengthens problem-solving abilities, operational efficiency, and readiness for scenario-based questions in the exam. System proficiency ensures candidates can navigate complex supply chain operations confidently.

Collaborative Learning and Knowledge Sharing

Engaging with professional communities and peers supports learning through shared experiences and discussions. Candidates can exchange solutions, explore diverse approaches, and gain insights into best practices. Collaborative learning reinforces understanding, maintains motivation, and develops teamwork skills that are valuable for supply chain operations. Exposure to multiple perspectives enhances problem-solving and decision-making capabilities.

Simulation and Practice Assessment

Regular practice assessments help candidates evaluate their readiness for the MB-330 exam. Simulated tests provide insight into question formats, time management, and scenario-based problem-solving. Practice assessments identify areas of strength and highlight topics requiring additional focus. Consistent practice builds confidence, reduces exam anxiety, and ensures candidates are prepared to handle integrated supply chain challenges under timed conditions.

Integrated Module Awareness

Candidates must understand interdependencies among inventory, procurement, warehouse, transportation, quality, and master planning modules. Awareness of module interactions ensures accurate execution of transactions, consistent reporting, and efficient resource allocation. Integrated knowledge is essential for managing end-to-end supply chain processes and ensures operational cohesion and reliability.

Advanced Planning and Resource Management

Candidates should be proficient in coordinating production schedules, managing safety stock, and optimizing inventory levels. Understanding master planning parameters, action messages, and planning periods ensures effective allocation of resources. Advanced planning skills enhance operational efficiency, reduce production delays, and ensure timely fulfillment of customer orders. Mastery of resource management supports overall supply chain optimization.

Decision-Making Under Constraints

The exam tests candidates’ ability to make informed decisions under operational constraints. Candidates should analyze data, evaluate alternative solutions, and implement optimal actions. Decision-making skills enable the resolution of supply chain disruptions, improve efficiency, and ensure continuity of operations. Practicing decision-making enhances readiness for scenario-based questions and real-world supply chain challenges.

Continuous Improvement and Learning

Ongoing learning is essential to maintain expertise in Dynamics 365 Supply Chain Management. Candidates should stay updated with system enhancements, new functionalities, and evolving operational strategies. Emphasizing continuous improvement ensures long-term proficiency, adaptability, and professional growth. This mindset enables candidates to optimize processes, implement best practices, and respond effectively to dynamic supply chain environments.

Operational Efficiency and Monitoring

Candidates should be able to monitor performance across all supply chain functions, including inventory, procurement, warehouse, and transportation. Evaluating performance metrics, identifying inefficiencies, and implementing corrective actions ensures smooth operations. Operational efficiency contributes to cost savings, improved throughput, and enhanced service levels. Mastery of monitoring techniques allows for proactive management of potential disruptions.

Transportation Coordination and Route Optimization

Coordinating transportation operations includes managing carriers, planning routes, scheduling deliveries, and reconciling freight invoices. Integration with warehouse and inventory systems ensures that shipments are executed efficiently and on time. Candidates should be able to analyze logistics performance, optimize load planning, and implement cost-effective routing strategies. Efficient transportation coordination enhances supply chain responsiveness and reduces operational costs.

Quality Control and Compliance Management

Maintaining product quality and compliance is critical. Candidates should implement quality orders, manage inspection processes, and handle nonconformance situations effectively. Configuring quality associations and monitoring quarantine procedures ensures adherence to standards. Quality control improves product reliability, minimizes operational risks, and strengthens customer satisfaction. Understanding compliance requirements is crucial for sustaining operational integrity.

Asset Tracking and Maintenance Coordination

Effective asset management involves scheduling maintenance, managing work orders, and tracking functional locations. Integration with inventory and warehouse operations ensures assets are available and functional when needed. Proper management of preventive and reactive maintenance minimizes downtime, improves productivity, and supports operational continuity. Knowledge of asset tracking contributes to overall supply chain efficiency.

Analytical Reporting and Trend Analysis

Generating detailed reports and analyzing trends enables candidates to monitor supply chain performance. Reporting on inventory levels, procurement efficiency, warehouse operations, and transportation metrics provides actionable insights. Trend analysis supports demand forecasting, process improvements, and strategic decision-making. Analytical skills enhance visibility into operations and enable timely corrective actions.

System Configuration for Optimal Performance

Candidates should be able to configure system parameters across modules to streamline supply chain processes. Configuring warehouses, inventory, procurement workflows, transportation plans, and quality management ensures operational alignment and accuracy. Optimized system configurations reduce errors, improve efficiency, and facilitate seamless integration across supply chain functions. Proper configuration is essential for achieving consistent operational performance.

Forecasting and Master Planning Execution

Running master planning, evaluating coverage groups, and managing planning parameters is essential for aligning supply with demand. Candidates should manage safety stock, action messages, and delay messages to ensure timely production and delivery. Accurate forecasting and master planning improve resource utilization, reduce excess inventory, and support organizational goals. Mastery of these planning functions prepares candidates for dynamic operational scenarios and the exam.

Cost Analysis and Trade Agreement Management

Candidates must manage costing methods, trade agreements, and pricing strategies to maintain financial accuracy. Configuring standard costs, maintaining costing versions, and managing item price groups ensures correct reporting. Knowledge of pricing structures, cost type codes, and auto-cost calculations supports profitability, informed decision-making, and operational efficiency. Effective cost management is a key component of integrated supply chain performance.

Practical Scenario Application

Engaging with real-world scenarios allows candidates to apply theoretical knowledge in practical contexts. Handling procurement delays, inventory discrepancies, transportation issues, and intercompany transactions enhances problem-solving skills. Scenario-based practice strengthens decision-making, reinforces system knowledge, and prepares candidates for the integrated nature of the MB-330 exam.

Professional Preparedness

Proficiency in Dynamics 365 Supply Chain Management demonstrates readiness to manage complex operations. Candidates gain competence in inventory, procurement, warehouse, transportation, quality, and master planning processes. Applied knowledge ensures operational efficiency, effective resource allocation, and informed decision-making. Mastery of these areas prepares candidates for both professional roles and successful completion of the MB-330 exam.

End-to-End Supply Chain Management

Understanding the interdependencies between modules and processes is crucial for optimizing end-to-end supply chain operations. Candidates should be able to evaluate impacts, coordinate activities, and implement solutions across inventory, procurement, warehouse, transportation, and quality functions. End-to-end management ensures operational cohesion, reduces errors, and supports consistent performance throughout the supply chain.

Conclusion

Preparing for the MB-330 exam requires a comprehensive understanding of Microsoft Dynamics 365 Supply Chain Management and its diverse functionalities. Candidates must develop proficiency across multiple domains, including inventory management, procurement, warehouse operations, transportation planning, quality assurance, asset management, master planning, and financial integration. Each of these areas is interconnected, requiring candidates to understand not only individual processes but also how changes in one module can affect overall supply chain operations.

Hands-on experience with the system is crucial for reinforcing theoretical knowledge. Practicing real-world scenarios, managing inventory journals, executing purchase and sales orders, configuring warehouses, and coordinating transportation processes helps candidates build confidence and operational competence. Scenario-based exercises and simulations enable learners to apply knowledge in practical contexts, develop problem-solving skills, and become adept at managing complex workflows under time constraints.

Analytical and reporting skills are essential for monitoring performance, identifying inefficiencies, and making informed decisions. Candidates must be able to generate actionable insights from data, forecast demand accurately, optimize resource allocation, and ensure smooth execution of supply chain processes. Workflow automation, integrated process management, and advanced planning techniques further enhance operational efficiency, reduce errors, and support timely order fulfillment.

Continuous learning and adaptability are also key components of success. Supply chain operations evolve rapidly, and staying updated with system functionalities, process improvements, and industry best practices ensures long-term proficiency. Collaboration with peers and engagement with professional communities provides additional perspectives, enhances knowledge, and fosters effective problem-solving approaches.

Ultimately, the MB-330 exam evaluates a candidate’s ability to manage end-to-end supply chain operations effectively. By mastering system configuration, integrated processes, analytical reporting, and scenario-based problem-solving, candidates demonstrate operational readiness and professional competence. Thorough preparation, practical experience, and consistent practice enable candidates to approach the exam with confidence, ensuring success and the ability to contribute effectively in supply chain management roles.

Microsoft Dynamics 365 MB-330 practice test questions and answers, training course, study guide are uploaded in ETE Files format by real users. Study and Pass MB-330 Microsoft Dynamics 365 Supply Chain Management certification exam dumps & practice test questions and answers are to help students.

Exam Comments * The most recent comment are on top

- AZ-104 - Microsoft Azure Administrator

- AI-900 - Microsoft Azure AI Fundamentals

- AI-102 - Designing and Implementing a Microsoft Azure AI Solution

- AZ-305 - Designing Microsoft Azure Infrastructure Solutions

- DP-700 - Implementing Data Engineering Solutions Using Microsoft Fabric

- MD-102 - Endpoint Administrator

- PL-300 - Microsoft Power BI Data Analyst

- AZ-900 - Microsoft Azure Fundamentals

- MS-102 - Microsoft 365 Administrator

- AZ-500 - Microsoft Azure Security Technologies

- SC-300 - Microsoft Identity and Access Administrator

- SC-200 - Microsoft Security Operations Analyst

- SC-401 - Administering Information Security in Microsoft 365

- DP-600 - Implementing Analytics Solutions Using Microsoft Fabric

- AZ-700 - Designing and Implementing Microsoft Azure Networking Solutions

- AZ-204 - Developing Solutions for Microsoft Azure

- SC-100 - Microsoft Cybersecurity Architect

- PL-200 - Microsoft Power Platform Functional Consultant

- AZ-400 - Designing and Implementing Microsoft DevOps Solutions

- PL-400 - Microsoft Power Platform Developer

- AZ-140 - Configuring and Operating Microsoft Azure Virtual Desktop

- AZ-800 - Administering Windows Server Hybrid Core Infrastructure

- SC-900 - Microsoft Security, Compliance, and Identity Fundamentals

- PL-600 - Microsoft Power Platform Solution Architect

- GH-300 - GitHub Copilot

- DP-300 - Administering Microsoft Azure SQL Solutions

- MS-900 - Microsoft 365 Fundamentals

- MS-700 - Managing Microsoft Teams

- AZ-801 - Configuring Windows Server Hybrid Advanced Services

- PL-900 - Microsoft Power Platform Fundamentals

- MB-280 - Microsoft Dynamics 365 Customer Experience Analyst

- MB-330 - Microsoft Dynamics 365 Supply Chain Management

- MB-800 - Microsoft Dynamics 365 Business Central Functional Consultant

- DP-900 - Microsoft Azure Data Fundamentals

- AB-730 - AI Business Professional

- MB-310 - Microsoft Dynamics 365 Finance Functional Consultant

- DP-100 - Designing and Implementing a Data Science Solution on Azure

- MB-820 - Microsoft Dynamics 365 Business Central Developer

- MB-230 - Microsoft Dynamics 365 Customer Service Functional Consultant

- MS-721 - Collaboration Communications Systems Engineer

- MB-700 - Microsoft Dynamics 365: Finance and Operations Apps Solution Architect

- PL-500 - Microsoft Power Automate RPA Developer

- MB-500 - Microsoft Dynamics 365: Finance and Operations Apps Developer

- GH-900 - GitHub Foundations

- MB-335 - Microsoft Dynamics 365 Supply Chain Management Functional Consultant Expert

- GH-200 - GitHub Actions

- AB-100 - Agentic AI Business Solutions Architect

- GH-500 - GitHub Advanced Security

- DP-420 - Designing and Implementing Cloud-Native Applications Using Microsoft Azure Cosmos DB

- MB-240 - Microsoft Dynamics 365 for Field Service

- AB-731 - AI Transformation Leader

- GH-100 - GitHub Administration

- MB-910 - Microsoft Dynamics 365 Fundamentals Customer Engagement Apps (CRM)

- MB-920 - Microsoft Dynamics 365 Fundamentals Finance and Operations Apps (ERP)

- AZ-120 - Planning and Administering Microsoft Azure for SAP Workloads

- DP-203 - Data Engineering on Microsoft Azure

- SC-400 - Microsoft Information Protection Administrator

- 62-193 - Technology Literacy for Educators

- AZ-303 - Microsoft Azure Architect Technologies

- 98-383 - Introduction to Programming Using HTML and CSS

- MO-100 - Microsoft Word (Word and Word 2019)

- MO-300 - Microsoft PowerPoint (PowerPoint and PowerPoint 2019)

- MB-210 - Microsoft Dynamics 365 for Sales

Purchase MB-330 Exam Training Products Individually

Why customers love us?

What do our customers say?

The resources provided for the Microsoft certification exam were exceptional. The exam dumps and video courses offered clear and concise explanations of each topic. I felt thoroughly prepared for the MB-330 test and passed with ease.

Studying for the Microsoft certification exam was a breeze with the comprehensive materials from this site. The detailed study guides and accurate exam dumps helped me understand every concept. I aced the MB-330 exam on my first try!

I was impressed with the quality of the MB-330 preparation materials for the Microsoft certification exam. The video courses were engaging, and the study guides covered all the essential topics. These resources made a significant difference in my study routine and overall performance. I went into the exam feeling confident and well-prepared.

The MB-330 materials for the Microsoft certification exam were invaluable. They provided detailed, concise explanations for each topic, helping me grasp the entire syllabus. After studying with these resources, I was able to tackle the final test questions confidently and successfully.

Thanks to the comprehensive study guides and video courses, I aced the MB-330 exam. The exam dumps were spot on and helped me understand the types of questions to expect. The certification exam was much less intimidating thanks to their excellent prep materials. So, I highly recommend their services for anyone preparing for this certification exam.

Achieving my Microsoft certification was a seamless experience. The detailed study guide and practice questions ensured I was fully prepared for MB-330. The customer support was responsive and helpful throughout my journey. Highly recommend their services for anyone preparing for their certification test.

I couldn't be happier with my certification results! The study materials were comprehensive and easy to understand, making my preparation for the MB-330 stress-free. Using these resources, I was able to pass my exam on the first attempt. They are a must-have for anyone serious about advancing their career.

The practice exams were incredibly helpful in familiarizing me with the actual test format. I felt confident and well-prepared going into my MB-330 certification exam. The support and guidance provided were top-notch. I couldn't have obtained my Microsoft certification without these amazing tools!

The materials provided for the MB-330 were comprehensive and very well-structured. The practice tests were particularly useful in building my confidence and understanding the exam format. After using these materials, I felt well-prepared and was able to solve all the questions on the final test with ease. Passing the certification exam was a huge relief! I feel much more competent in my role. Thank you!

The certification prep was excellent. The content was up-to-date and aligned perfectly with the exam requirements. I appreciated the clear explanations and real-world examples that made complex topics easier to grasp. I passed MB-330 successfully. It was a game-changer for my career in IT!