- Home

- ASQ Certifications

- CQE Certified Quality Engineer Dumps

Pass ASQ CQE Exam in First Attempt Guaranteed!

Get 100% Latest Exam Questions, Accurate & Verified Answers to Pass the Actual Exam!

30 Days Free Updates, Instant Download!

CQE Premium Bundle

- Premium File 160 Questions & Answers. Last update: Feb 04, 2026

- Training Course 347 Video Lectures

Last Week Results!

Includes question types found on the actual exam such as drag and drop, simulation, type-in and fill-in-the-blank.

Based on real-life scenarios similar to those encountered in the exam, allowing you to learn by working with real equipment.

All ASQ CQE certification exam dumps, study guide, training courses are Prepared by industry experts. PrepAway's ETE files povide the CQE Certified Quality Engineer practice test questions and answers & exam dumps, study guide and training courses help you study and pass hassle-free!

Unlocking Career Opportunities with the CQE Certification

A Certified Quality Engineer plays a pivotal role in bridging technical knowledge and practical application within an organization. Their responsibilities extend beyond traditional quality control, encompassing strategic planning, process optimization, and compliance oversight. CQEs are expected to possess a thorough understanding of statistical methods, quality management systems, and process design principles, enabling them to implement systematic improvements across various operational functions. They are often called upon to evaluate existing procedures, detect inefficiencies, and recommend evidence-based solutions that enhance performance, reduce variability, and ensure compliance with regulatory requirements. By applying their expertise, CQEs help organizations achieve consistent product quality, improve customer satisfaction, and maintain competitive advantage in increasingly regulated and complex markets.

A core aspect of the CQE role involves integrating quality engineering principles into organizational strategy. This integration requires an in-depth understanding of how different quality systems interact with production, operations, and supply chain processes. CQEs evaluate these systems holistically, identifying overlaps, redundancies, and gaps that could affect overall performance. By linking quality management activities to broader business objectives, they ensure that quality improvements are not isolated initiatives but contribute meaningfully to operational efficiency and organizational growth. The ability to align quality goals with strategic priorities is a critical skill tested during the certification process, reflecting the practical expectations of the profession.

Data-driven decision making is another central responsibility of a Certified Quality Engineer. CQEs must be adept at collecting, analyzing, and interpreting data to support operational decisions and process improvements. Statistical tools, including regression analysis, hypothesis testing, and process capability studies, allow engineers to identify trends, predict potential failures, and implement proactive solutions. Data analysis supports both tactical and strategic decisions, from optimizing individual processes to guiding long-term organizational policies. Mastery of these analytical techniques ensures that CQEs can provide reliable recommendations based on quantitative evidence, fostering confidence among stakeholders and enhancing the credibility of quality initiatives.

Leadership is a significant component of the CQE role, as these professionals often guide teams, mentor junior staff, and influence organizational culture. Effective leadership in quality engineering involves setting clear objectives, motivating employees, and fostering an environment of continuous improvement. CQEs lead cross-functional teams in projects that require collaboration between production, operations, and management, ensuring that quality standards are maintained throughout the organization. They also play a key role in resolving conflicts, facilitating communication between departments, and ensuring alignment between quality objectives and business goals. Leadership skills are essential for driving sustainable improvements, gaining buy-in from stakeholders, and demonstrating professional credibility.

Continuous improvement is fundamental to the work of a Certified Quality Engineer. CQEs are expected to apply methodologies such as Lean, Six Sigma, and Total Quality Management to identify inefficiencies and implement process enhancements. They conduct root cause analyses, design experiments, and develop strategies to eliminate variability, reduce waste, and optimize performance. Continuous improvement is not merely a theoretical concept but a practical, ongoing commitment to refining processes in response to operational challenges. Engineers in this role must balance methodological rigor with adaptability, tailoring improvement initiatives to the unique circumstances of their organization. Proficiency in continuous improvement techniques is a key focus of the certification exam and reflects the hands-on capabilities required in real-world applications.

Supplier quality and customer satisfaction are closely linked areas of responsibility for CQEs. Ensuring that suppliers deliver materials or services that meet defined quality standards is essential to maintaining consistent output and preventing defects. Certified Quality Engineers assess supplier performance through audits, process evaluations, and corrective action programs, ensuring that any deviations are addressed promptly. On the customer side, CQEs focus on understanding expectations, analyzing feedback, and implementing changes that improve product quality and service delivery. This dual focus strengthens the overall quality ecosystem and demonstrates the professional’s ability to manage complex interactions between internal processes, suppliers, and customers.

Ethical and professional responsibilities underpin every aspect of the CQE role. Certified Quality Engineers must adhere to principles of integrity, accountability, and transparency in all audits, evaluations, and recommendations. Ethical decision-making ensures that reports, findings, and improvements reflect accurate, unbiased assessments of systems and processes. CQEs are expected to act in the best interest of their organization while maintaining compliance with regulatory standards and professional guidelines. Upholding ethical standards enhances trust, supports regulatory compliance, and reinforces the credibility of quality initiatives, which is particularly important in highly regulated industries.

Certification as a quality engineer validates both technical competence and professional integrity. Accredited programs confirm that candidates meet rigorous criteria for knowledge, experience, and ethical conduct, providing assurance to employers and industry peers. Certification reflects a commitment to continuous learning, mastery of quality engineering principles, and the ability to apply knowledge effectively in practical situations. This recognition is often associated with career advancement opportunities, increased responsibilities, and enhanced influence within an organization.

In addition to technical skills, Certified Quality Engineers are expected to manage complex projects that require coordination across multiple departments. They must plan, execute, and monitor quality initiatives, ensuring that objectives are met on time and within budget. Project management skills, including resource allocation, risk assessment, and performance tracking, are integral to their role. The ability to balance multiple priorities while maintaining high-quality standards distinguishes CQEs as valuable contributors to organizational success.

Furthermore, CQEs play a crucial role in fostering a culture of quality within their organizations. They promote awareness of quality standards, train employees on best practices, and encourage proactive identification of issues before they escalate. By embedding quality into the organizational culture, CQEs ensure that improvements are sustainable and that all team members take ownership of quality outcomes. This cultural impact amplifies the effectiveness of technical interventions and supports long-term organizational excellence.

The CQE certification process itself emphasizes a comprehensive understanding of the Body of Knowledge, which covers statistical methods, quality management systems, product and process design, and leadership in quality initiatives. Candidates are tested on their ability to apply these concepts in real-world scenarios, demonstrating both theoretical understanding and practical competence. Preparing for the exam requires structured study, hands-on application, and continuous self-assessment, mirroring the skills and responsibilities expected in professional practice.

Certified Quality Engineers also contribute to risk management by identifying potential quality failures and developing strategies to mitigate them. This proactive approach reduces operational disruptions, enhances reliability, and ensures compliance with regulatory and contractual requirements. Risk assessment and mitigation are critical for maintaining consistent performance and supporting informed decision-making at all organizational levels.

Finally, CQEs are often involved in continuous education and professional development. Staying updated on emerging standards, technological advances, and best practices ensures that they remain effective in dynamic environments. Certification is not merely a milestone but a foundation for ongoing professional growth, enabling engineers to drive innovation, lead improvements, and maintain the highest levels of quality in their organizations. Through these combined responsibilities, Certified Quality Engineers ensure that products, processes, and systems consistently meet or exceed expectations, providing significant value to organizations and reinforcing their role as key contributors to operational excellence.

Eligibility Requirements for Certification

To qualify for certification as a quality engineer, candidates must meet specific professional experience criteria. Typically, eight years of full-time, paid work experience in areas relevant to the quality engineer body of knowledge are required. Of these, at least three years should involve decision-making responsibilities, defined as the authority to define, execute, or control projects and processes, and to be accountable for their outcomes.

Certain educational achievements can reduce the required professional experience. For example, completing a technical diploma, associate degree, bachelor's degree, or higher can waive between one and five years of experience. This provision recognizes the combination of academic knowledge and practical experience in building a competent quality professional.

Experience used to qualify for related quality certifications may also apply toward the CQE credential. This flexibility acknowledges the overlapping expertise across roles such as quality auditing, reliability engineering, and supplier quality management.

Preparing for the CQE Examination

Preparation for the quality engineer exam involves understanding the body of knowledge and systematically studying the topics covered. The exam evaluates comprehension across multiple domains, emphasizing both theoretical knowledge and practical application. Candidates are expected to be proficient in quality engineering principles, process improvement techniques, statistical tools, and regulatory compliance practices.

A structured study approach is recommended. Reviewing reference materials and relevant literature helps candidates develop a deep understanding of concepts. Integrating practical examples into preparation enhances the ability to apply knowledge in real-world scenarios, which is critical for success on the exam. Candidates are encouraged to familiarize themselves with all topics in the body of knowledge to ensure comprehensive coverage.

Examination Details and Format

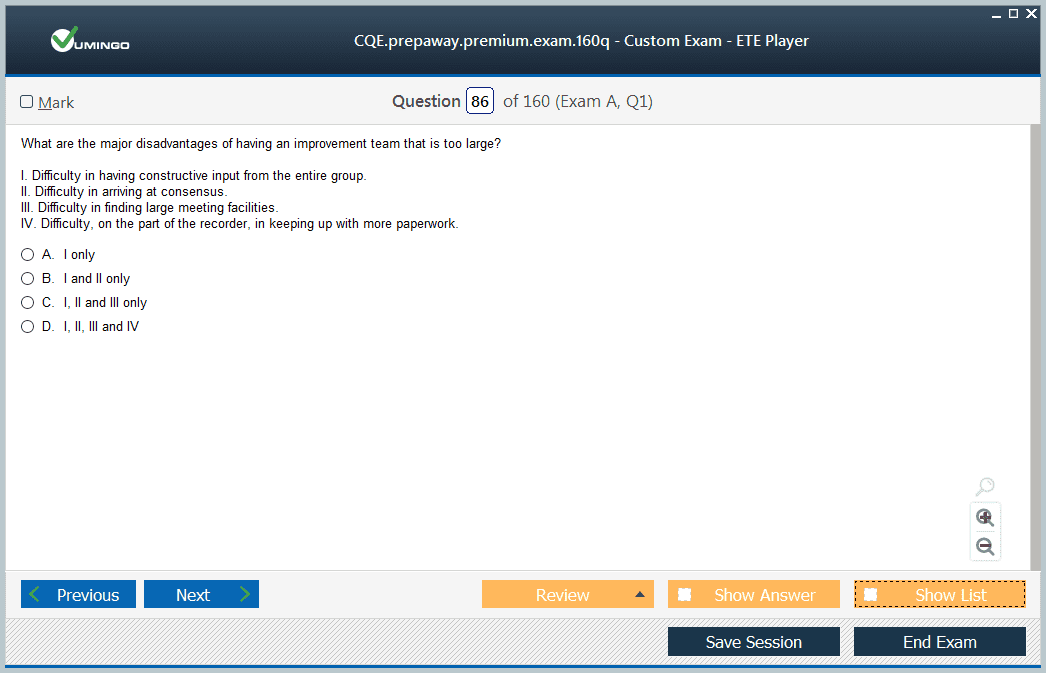

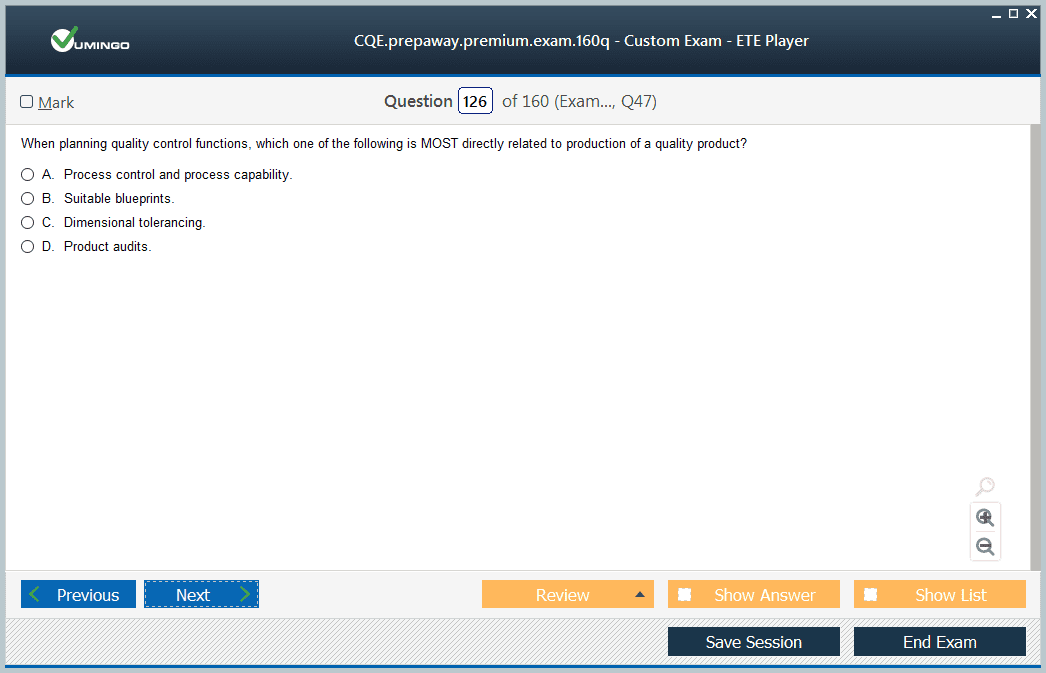

The CQE examination is available in computer-based and paper-based formats. The computer-based exam typically consists of 175 multiple-choice questions, with 160 scored and 15 unscored, and is administered in English. The total appointment time is five and a half hours, with a five-hour and eighteen-minute testing period. Paper-based exams consist of 160 questions and may be offered in additional languages in select locations.

The exam is open book, allowing candidates to reference their materials during testing. However, success requires familiarity with the content, as the allotted time is insufficient to look up every answer. Calculators and reference materials are permitted, and candidates should practice using these tools efficiently to optimize performance during the examination.

Exam Results and Certification Outcomes

Upon completion of the exam, candidates are informed of their results. Computer-based test-takers receive immediate preliminary feedback, followed by confirmation and instructions for claiming digital certification credentials. Paper-based results may take longer to process.

Successful candidates are awarded the certified quality engineer credential, which is recognized as a mark of professional competence and commitment to quality. Those who do not pass can retake the exam within a designated period at a reduced fee. The credential itself does not expire, and certified professionals can leverage it to advance their careers, enhance credibility, and take on more significant responsibilities within their organizations.

The CQE credential signifies mastery of quality engineering principles, the ability to apply statistical and analytical methods, and a commitment to continuous improvement. Certified professionals contribute to higher organizational efficiency, improved product quality, and compliance with industry standards. They are equipped to lead quality initiatives, implement effective process controls, and foster a culture of excellence across teams and departments.

Preparing Effectively for the Certified Quality Engineer Exam

Success in the CQE exam requires a focused and structured study approach. Understanding the body of knowledge is the first step, as it serves as the blueprint for the exam. The body of knowledge outlines the key domains, including management and leadership in quality, quality systems and audits, product and process design, statistical methods, and continuous improvement tools. Each domain has specific subtopics and cognitive levels that indicate the depth of understanding expected from candidates. Familiarity with this framework allows candidates to plan their study schedules strategically and allocate time according to the weight and complexity of each domain.

To begin preparation, candidates should gather relevant reference materials that cover all aspects of the body of knowledge. These materials typically include textbooks on quality engineering, statistical analysis guides, standards documentation, and published audit procedures. Open-book preparation is essential because, although the exam allows reference materials, the time constraints make it impossible to look up every answer. Therefore, candidates should become highly familiar with the organization of their materials, key formulas, and frequently referenced methodologies.

Study Plan and Time Management

A structured study plan is crucial for comprehensive preparation. Candidates should start with a foundation phase, focusing on gaining a complete overview of all exam domains. During this phase, they can read through textbooks and study guides, take notes, and map topics against the body of knowledge. Identifying areas of strength and weakness early helps prioritize subsequent study efforts.

After the foundation phase, candidates should enter a deep-dive phase. This involves revisiting challenging areas and applying practical examples to understand how concepts are used in real-world quality engineering scenarios. Practical application is critical because the CQE exam tests the ability to analyze situations, identify process improvements, and apply statistical and analytical methods to ensure quality and compliance. Using past case studies, process audits, and problem-solving exercises helps reinforce these skills.

The practice phase is the next critical step. Candidates should take full-length timed practice exams under conditions that simulate the real testing environment. This not only improves time management skills but also helps identify gaps in knowledge. Reviewing each incorrect or uncertain response allows candidates to strengthen weak areas and gain confidence in decision-making. Microlearning techniques, such as flashcards for formulas, definitions, and quality tools, are effective for retaining key information.

Finally, a review and reinforcement phase ensures that all domains are refreshed prior to the exam. This includes revisiting notes, summaries, and practice problems, as well as focusing on high-weight domains such as quality systems, auditing practices, and statistical analysis. Consistent review helps solidify understanding and reduces exam-day anxiety.

Key Domains and Their Significance

The CQE exam evaluates knowledge across several core domains, each contributing to the overall competence of a quality engineer. Management and leadership topics assess the candidate’s ability to guide quality initiatives, implement policies, and maintain compliance. Understanding quality systems and audits is critical for evaluating processes, identifying nonconformities, and ensuring adherence to standards. Product and process design knowledge ensures that quality considerations are integrated into development and manufacturing processes from the outset.

Statistical methods are central to the CQE role. Candidates are expected to apply tools such as process control charts, measurement system analysis, capability studies, and hypothesis testing. These methods allow professionals to make data-driven decisions, monitor performance, and drive process improvements. Continuous improvement techniques, including lean principles, Six Sigma methodologies, and root cause analysis, are also tested to ensure that candidates can sustain quality gains over time.

Strategies for Exam Success

Effective exam strategies extend beyond content mastery. Time management during the exam is crucial, as candidates must navigate 160 scored questions within a five-hour period. Prioritizing questions, answering confidently when possible, and flagging uncertain items for review are essential techniques. Analytical reading and critical thinking skills are vital, particularly for scenario-based questions that require application of concepts rather than rote recall.

Familiarity with reference materials is another key strategy. Knowing where to quickly find formulas, standards, and procedures reduces the time spent searching during the exam. Candidates should practice retrieving information from their resources efficiently, which can significantly improve exam performance.

Integrating Practical Experience

Practical experience is a distinguishing factor for CQE candidates. Engaging with real-life quality improvement projects, audits, and statistical analyses enhances understanding and allows candidates to relate theoretical knowledge to actual situations. Experience in decision-making roles, such as leading process improvement initiatives or overseeing audit programs, strengthens the ability to tackle complex exam scenarios and provides a solid foundation for certification.

Hands-on experience in quality systems, such as implementing ISO standards, conducting supplier audits, and developing measurement systems, is invaluable. Candidates can simulate these experiences in study exercises to reinforce learning and improve problem-solving abilities. Applying statistical tools to actual process data helps internalize methodologies and prepares candidates for scenario-based questions.

Continuous Review and Assessment

Continuous review is essential throughout the preparation period. Candidates should regularly assess their understanding of each domain, track performance on practice exams, and adjust their study plan accordingly. Using a combination of practice questions, reference reviews, and scenario-based exercises ensures comprehensive preparation. Candidates should also prioritize areas with higher question weight, such as auditing processes, quality tools, and statistical analysis, to maximize their performance potential.

By combining structured study, practical application, and strategic exam techniques, candidates can build the confidence and competence required to pass the CQE exam. Mastery of the body of knowledge, reinforced through continuous assessment and real-world experience, equips professionals to excel not only in the certification process but also in their ongoing careers as quality engineers.

Risk Management and Reliability Engineering

Risk management and reliability engineering are integral components of the Certified Quality Engineer exam. Candidates are expected to understand methods for identifying, assessing, and mitigating risks within manufacturing, service, or development processes. This involves both proactive and reactive approaches to potential quality issues. Reliability engineering focuses on ensuring that products, systems, or processes consistently perform as intended over their expected life span. This requires knowledge of failure modes, effects analysis, and reliability testing methods.

The CQE exam evaluates the ability to perform risk assessments, develop contingency plans, and integrate reliability principles into quality management systems. Tools such as fault tree analysis, failure mode and effects analysis, and reliability block diagrams are frequently tested. Understanding how to interpret reliability metrics, such as mean time to failure, failure rate, and availability, ensures that engineers can make data-driven decisions to improve product performance and system dependability.

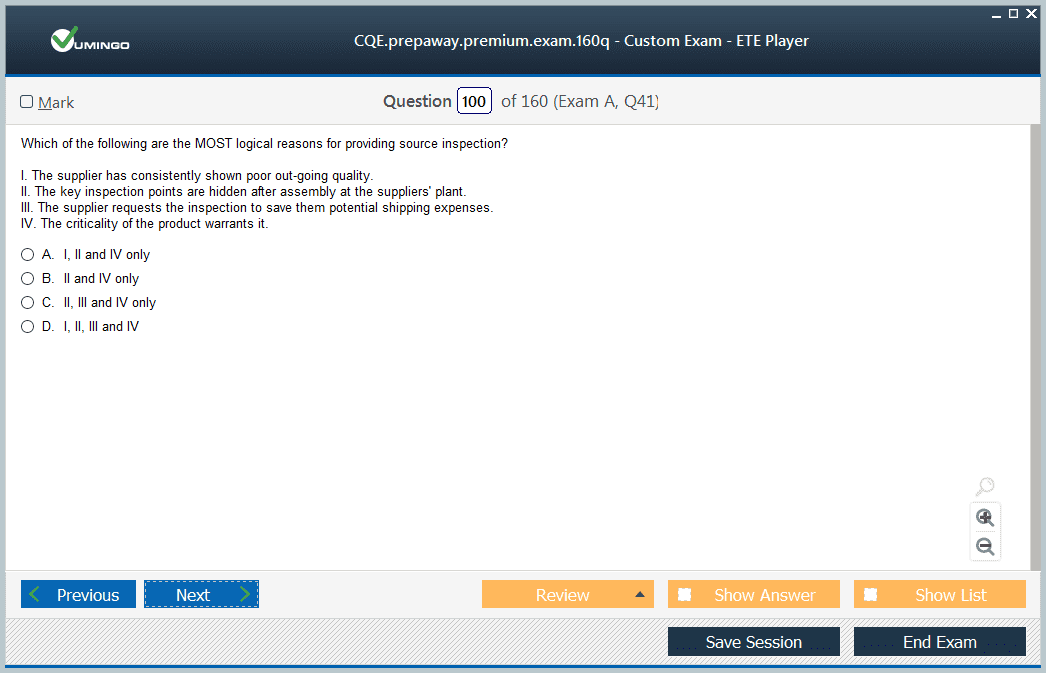

Supplier and Materials Quality

A significant part of a CQE’s role involves ensuring that suppliers and materials meet the required quality standards. Candidates are tested on their ability to assess supplier capabilities, evaluate incoming materials, and manage supplier relationships to maintain consistent quality. The exam may cover methods for auditing suppliers, establishing quality agreements, and implementing corrective actions for non-conformance.

Knowledge of statistical techniques for evaluating supplier performance, including control charts and process capability studies, is essential. Engineers must be able to integrate supplier quality considerations into the overall quality management system, ensuring that the supply chain supports organizational objectives and maintains compliance with industry standards. Understanding regulatory requirements, material specifications, and testing protocols is also necessary for both practical application and exam readiness.

Process Improvement and Lean Principles

Process improvement is a core responsibility of a certified quality engineer. The CQE exam emphasizes the application of methodologies to enhance efficiency, reduce waste, and improve product and service quality. Lean principles, Six Sigma approaches, and continuous improvement strategies are central topics. Candidates are expected to identify inefficiencies, analyze root causes, and implement corrective and preventive measures.

Techniques such as value stream mapping, Kaizen events, and the application of statistical process control allow engineers to optimize processes. Understanding how to balance cost, time, and quality while implementing improvements is critical. The exam tests the ability to design experiments, interpret data, and recommend changes that lead to measurable improvements in performance and customer satisfaction.

Documentation and Reporting

Effective documentation and reporting are essential skills for quality engineers. Candidates must demonstrate the ability to prepare clear, concise, and accurate reports of audit findings, process analyses, and improvement initiatives. The exam may assess knowledge of report formats, data presentation, and interpretation of results.

Documentation serves multiple purposes: communicating findings to stakeholders, supporting decision-making, and providing records for compliance and traceability. Engineers must understand best practices for organizing information, presenting statistical analyses, and drawing actionable conclusions. The ability to convey complex technical information in an understandable manner is a key factor in both professional effectiveness and exam performance.

Regulatory Compliance and Standards

Certified Quality Engineers must have a thorough understanding of industry regulations and standards relevant to their field. The CQE exam tests knowledge of ISO standards, regulatory requirements, and quality management frameworks. Candidates are expected to demonstrate how these standards guide process development, product design, and auditing practices.

Compliance ensures that products meet customer and legal requirements, reduces risk, and supports market access. Engineers must understand the application of standards to both internal processes and external supplier operations. The ability to interpret standards and integrate them into daily quality practices is a critical component of the certification.

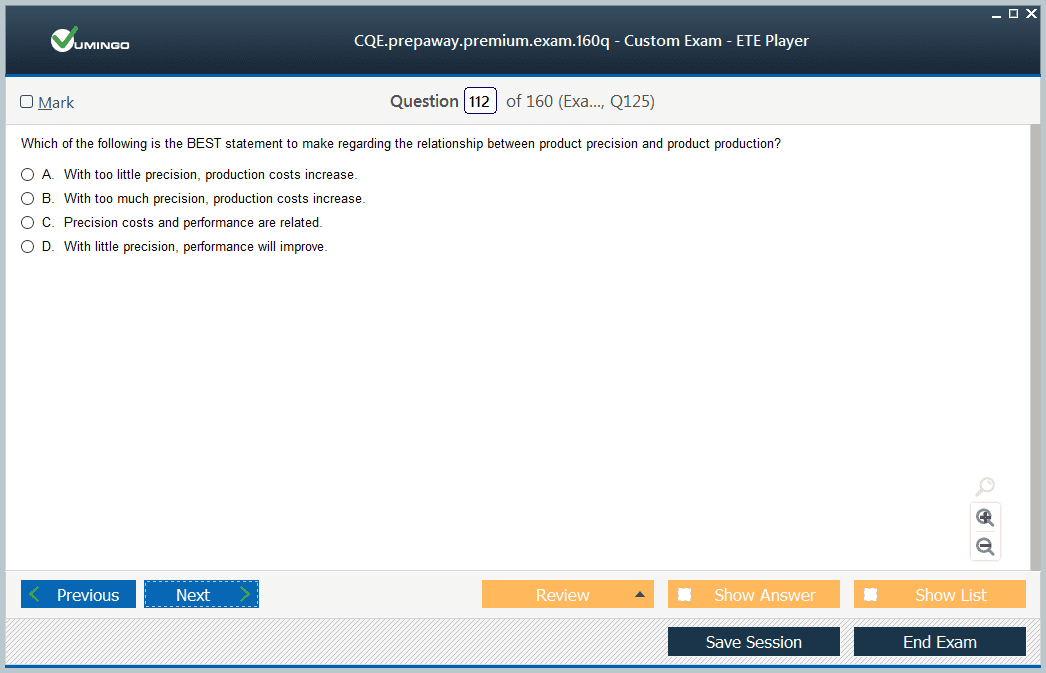

Practical Application of Quality Engineering Concepts

The CQE exam emphasizes not only theoretical knowledge but also practical application. Candidates are expected to integrate statistical tools, process improvement techniques, risk management, and auditing skills into real-world scenarios. Case studies, scenario-based questions, and applied problem-solving tasks assess the ability to translate knowledge into action.

Hands-on experience in quality engineering projects reinforces understanding and enhances exam preparedness. Simulating real-world conditions in practice exercises allows candidates to approach the exam with confidence, knowing they can apply concepts to practical situations.

Study Strategy and Exam Preparation

Preparation for the CQE exam requires a structured approach. Candidates should begin by thoroughly reviewing the body of knowledge, ensuring that all domains are covered comprehensively. Developing a study schedule that divides preparation into foundation, deep-dive, practice, and review phases ensures systematic learning.

Practice exams and scenario exercises are crucial for identifying gaps, reinforcing understanding, and improving time management. Focused review of weak areas, repeated practice, and integration of hands-on experience contribute to exam readiness. Understanding the exam structure, question formats, and cognitive levels allows candidates to approach each section strategically.

Successful certification demonstrates technical expertise, practical problem-solving ability, and leadership in quality management. It validates the capacity to influence process outcomes, drive continuous improvement, and contribute to organizational excellence.

Leadership in Quality Engineering

Leadership plays a crucial role in the responsibilities of a Certified Quality Engineer. Beyond technical knowledge, a CQE must guide teams, influence stakeholders, and drive organizational improvement initiatives. Effective leadership involves setting quality objectives, motivating team members, and fostering a culture of continuous improvement.

Leadership for a CQE extends beyond assigning tasks or monitoring compliance; it involves inspiring a vision for quality that aligns with the organization’s mission. This requires the ability to communicate complex technical concepts in an understandable manner, ensuring that all team members grasp the importance of their contributions. Quality engineers often serve as liaisons between management, production teams, and clients, requiring strong interpersonal skills to manage expectations and maintain trust.

Developing leadership capabilities also means mastering conflict resolution. In dynamic work environments, disagreements may arise over resource allocation, process changes, or audit findings. A CQE must navigate these challenges diplomatically, ensuring that decisions are data-driven, ethical, and aligned with quality standards. Exam questions may present scenarios where candidates must prioritize actions or mediate disputes, testing both judgment and leadership acumen.

Mentorship is another vital component of leadership in quality engineering. Experienced CQEs are expected to train junior staff, fostering skill development and encouraging adherence to best practices. By mentoring others, CQEs enhance team capability, reduce errors, and promote a culture of continuous learning. Leadership in quality is not only about immediate project outcomes but also about shaping long-term organizational resilience and adaptability.

Integration of Quality Systems

A Certified Quality Engineer must understand how different quality systems interact within an organization. Integration involves aligning quality assurance processes with operational, production, and compliance systems to achieve coherent and efficient workflows. The exam tests knowledge of systems integration, including how to link quality control, risk management, and audit programs effectively.

System integration requires a holistic view of organizational processes. CQEs need to evaluate how quality initiatives interact with supply chain operations, production schedules, and regulatory requirements. By identifying overlaps and gaps, they can streamline processes, reduce redundancies, and ensure that all quality efforts contribute to organizational objectives. Practical knowledge of systems integration is essential to answer exam questions that involve troubleshooting complex process networks or recommending improvements.

Understanding how to integrate quality systems also encompasses knowledge of auditing frameworks, documentation standards, and reporting protocols. Engineers are expected to recommend best practices for process alignment and continuous monitoring. This ensures that organizational quality objectives are met consistently and efficiently, reinforcing the value of the CQE role in both operational and strategic contexts.

Data-Driven Decision Making

The ability to make informed decisions based on data is central to the role of a Certified Quality Engineer. Candidates must demonstrate proficiency in statistical tools, measurement techniques, and data interpretation. The CQE exam includes questions on using data to identify trends, predict failures, and implement process improvements.

Data-driven decision making involves more than collecting numbers; it requires critical analysis and application. CQEs must interpret statistical process control charts, analyze measurement system variability, and apply regression analysis to forecast potential issues. By translating data into actionable recommendations, engineers can proactively address quality challenges and prevent defects before they escalate.

In addition, candidates should be adept at risk assessment based on quantitative analysis. Understanding probability distributions, process capability indices, and defect rates allows quality engineers to prioritize interventions where they will have the greatest impact. The ability to leverage data effectively is both a practical requirement in the workplace and a tested skill in the CQE examination.

Continuous Improvement Strategies

Continuous improvement is a foundational principle in quality engineering. Candidates are tested on methodologies such as Lean, Six Sigma, and Total Quality Management to enhance processes and eliminate inefficiencies. The CQE exam evaluates knowledge of tools and techniques for process improvement, including root cause analysis, PDCA cycles, and Kaizen events.

CQEs are expected to design and implement improvement initiatives that reduce variability, increase efficiency, and elevate product quality. This requires a combination of theoretical knowledge and practical application, ensuring that improvements are measurable and sustainable. Engineers must also consider human factors, resource availability, and process constraints when planning interventions.

Understanding the full spectrum of continuous improvement techniques allows CQEs to tailor solutions to organizational needs. For example, integrating Six Sigma with Lean principles can optimize workflows while minimizing waste. Demonstrating the ability to select and apply the right methodology underpins success both in the field and on the certification exam.

Supplier and Customer Quality Management

Managing supplier quality and ensuring customer satisfaction are critical responsibilities for CQEs. The exam covers techniques for evaluating supplier performance, implementing quality agreements, and monitoring product or service quality. Candidates are expected to apply tools for supplier audits, process capability assessments, and corrective action implementation.

Quality engineers act as the bridge between suppliers and internal processes. They ensure that materials meet required standards and that any deviations are addressed promptly. Tools such as supplier scorecards, audit checklists, and corrective action tracking help maintain consistent quality levels.

On the customer side, CQEs must understand expectations, analyze feedback, and implement improvements based on data. This ensures products and services meet or exceed client requirements, reinforcing trust and promoting brand loyalty. Knowledge in supplier and customer quality management is a recurring theme in the CQE exam, as it reflects the real-world responsibilities of quality engineers.

Advanced Statistical Techniques

Advanced statistical techniques form a significant portion of the CQE Body of Knowledge. Candidates must be proficient in methods such as design of experiments, capability analysis, reliability testing, and measurement system analysis. The exam tests the application of these tools to analyze data, identify process issues, and implement improvements.

CQEs are expected to understand the principles behind each statistical method, know how to calculate and interpret results, and apply findings to practical situations. Design of experiments enables systematic investigation of factors affecting quality, while reliability testing assesses the likelihood of product performance over time. Measurement system analysis ensures that instruments and procedures provide accurate and repeatable data. Mastery of these techniques equips engineers to make evidence-based decisions that enhance quality and efficiency.

Ethical and Professional Responsibilities

Ethical considerations and professional responsibilities are integral to the CQE role. Candidates must understand the principles of professional conduct, integrity in reporting, and accountability in decision-making. The exam evaluates the ability to apply ethical guidelines in auditing, quality management, and process improvement.

Ethics in quality engineering extends to transparent reporting of defects, unbiased audit findings, and adherence to regulatory standards. CQEs are expected to uphold these principles even under pressure, ensuring that organizational integrity is maintained. Understanding the ethical implications of decisions reinforces credibility and enhances the professional standing of the engineer.

Preparing for the CQE Exam

Thorough preparation for the CQE exam involves a structured study plan that integrates the Body of Knowledge, practical exercises, and continuous self-assessment. Candidates should allocate sufficient time to master each domain, including leadership, system integration, statistical analysis, continuous improvement, supplier and customer quality management, and ethical responsibilities.

Using practice exams and scenario-based questions simulates real testing conditions, helping candidates manage time effectively and identify areas for improvement. Combining theoretical study with real-world application ensures a deeper understanding of quality engineering principles and enhances readiness for exam challenges.

Career Impact of CQE Certification

Obtaining the Certified Quality Engineer (CQE) certification represents a significant milestone for professionals in the field of quality engineering. The credential demonstrates mastery of critical concepts, technical skills, and practical application of quality principles, providing tangible evidence of an individual’s competence to employers, peers, and stakeholders. This recognition not only validates technical knowledge but also highlights the professional’s ability to contribute meaningfully to process optimization, regulatory compliance, and overall organizational improvement.

The CQE certification enhances career prospects by distinguishing professionals in a competitive job market. Employers increasingly value candidates who have demonstrated formal competency in quality engineering principles, including statistical analysis, risk management, process design, and continuous improvement. Certified quality engineers are often considered for roles that require higher levels of responsibility, such as leading audit teams, managing quality programs, or overseeing compliance initiatives. By earning the CQE credential, professionals signal their readiness to take on complex challenges and deliver measurable results, thereby positioning themselves for promotions and advanced leadership roles within their organizations.

Beyond technical competence, the CQE certification emphasizes leadership and strategic thinking, which are crucial for career growth. Certified engineers are expected to guide cross-functional teams, communicate effectively with stakeholders, and influence organizational decisions related to quality and operational efficiency. These leadership capabilities make CQEs attractive candidates for managerial or supervisory positions where they can drive initiatives that enhance process performance, reduce defects, and support long-term business objectives. As organizations increasingly focus on quality-driven performance and operational excellence, certified professionals are uniquely positioned to assume key roles in shaping strategy and implementing best practices.

One of the notable impacts of CQE certification is its potential effect on compensation and professional recognition. Certified quality engineers often experience higher salary potential compared to their non-certified peers. The credential serves as evidence of the professional’s expertise, reliability, and commitment to excellence, which can influence hiring decisions, salary negotiations, and career progression. In addition to financial benefits, the recognition associated with CQE certification can enhance professional credibility, fostering trust with colleagues, supervisors, and clients. This credibility often translates into opportunities for greater influence within the organization, enabling certified engineers to champion quality initiatives and lead improvement projects effectively.

The career benefits of CQE certification extend beyond individual organizations. Certified quality engineers gain access to a professional network of peers, mentors, and industry experts, providing opportunities for collaboration, knowledge exchange, and continued professional development. Participation in professional communities allows CQEs to stay current with emerging trends, regulatory changes, and best practices in quality management. This continuous engagement enhances their ability to make informed decisions, implement innovative solutions, and maintain relevance in an evolving industry landscape. Furthermore, involvement in professional networks can open doors to speaking engagements, publications, and leadership positions within industry associations, further expanding career horizons.

CQE certification also facilitates career mobility across industries and geographies. The principles of quality engineering, such as process optimization, risk assessment, and statistical analysis, are applicable across a wide range of sectors, including manufacturing, healthcare, aerospace, automotive, and software development. Certified professionals are often sought after by organizations looking to implement robust quality systems and continuous improvement programs. The international recognition of the CQE credential allows professionals to pursue opportunities globally, broadening the scope of career options and enabling movement into roles that require cross-functional expertise and strategic oversight.

In addition to advancing individual careers, CQE-certified professionals contribute significantly to organizational success. By applying their knowledge and skills, they help companies reduce waste, improve product quality, enhance customer satisfaction, and ensure regulatory compliance. The ability to implement effective quality programs and identify process inefficiencies positions certified engineers as essential contributors to business performance. Organizations that employ CQEs often experience measurable improvements in operational efficiency, product reliability, and competitive advantage, reinforcing the value of investing in certified personnel.

Professional development through CQE certification also encourages lifelong learning and continuous improvement. The preparation process for the certification requires mastery of the Body of Knowledge, encompassing topics such as quality tools, reliability analysis, process management, and leadership. Maintaining certification often involves ongoing education and recertification, ensuring that professionals remain up-to-date with industry advancements and emerging methodologies. This commitment to continuous learning not only strengthens the engineer’s technical and leadership skills but also signals to employers a dedication to maintaining high standards of professional excellence.

Moreover, CQE certification provides a pathway for advancement into specialized roles within quality engineering. Certified engineers can leverage their expertise to transition into areas such as reliability engineering, risk management, supplier quality management, and quality auditing. The credential equips professionals with the analytical tools, leadership capabilities, and strategic insight needed to manage complex projects, drive cross-functional initiatives, and implement data-driven improvements. As organizations increasingly rely on certified professionals to lead transformation and operational excellence efforts, CQEs gain visibility and influence within executive decision-making processes.

Finally, the career impact of CQE certification extends to enhanced job satisfaction and professional fulfillment. Certified quality engineers are recognized for their ability to make meaningful contributions, lead impactful projects, and improve organizational performance. The combination of technical expertise, leadership responsibility, and strategic influence fosters a sense of accomplishment and professional pride. CQEs have the tools and knowledge to effect positive change within their organizations, positioning them not just as technical specialists but as trusted advisors and leaders in quality management.

In summary, the CQE certification serves as a catalyst for career advancement, professional recognition, and long-term growth in the field of quality engineering. It validates both technical and practical expertise, enhances leadership capabilities, and provides access to professional networks and global opportunities. Certified quality engineers are well-equipped to influence organizational performance, drive continuous improvement initiatives, and achieve measurable results. The credential represents a commitment to excellence, lifelong learning, and strategic contribution, establishing CQEs as indispensable professionals who support operational success, customer satisfaction, and sustainable business growth across industries.

Final Words

Certified Quality Engineers (CQEs) hold a critical position in ensuring that organizations operate at optimal efficiency while maintaining the highest standards of quality. Their role extends beyond technical execution, requiring them to integrate leadership, strategic thinking, and practical application into their daily responsibilities. CQEs are entrusted with analyzing processes, identifying inefficiencies, and implementing corrective measures that enhance both operational performance and product quality. This combination of analytical skill and practical insight enables them to make meaningful contributions to organizational goals, particularly in environments that demand strict compliance with regulatory and industry standards.

One of the defining features of the CQE role is the ability to apply statistical and analytical methods to drive informed decision-making. Proficiency in statistical process control, design of experiments, regression analysis, and measurement system evaluation equips engineers to identify trends, predict potential failures, and implement corrective strategies. By interpreting data accurately, CQEs can translate raw information into actionable insights that inform both tactical process adjustments and strategic organizational initiatives. This data-driven approach ensures that quality improvements are measurable, sustainable, and aligned with overall business objectives.

Leadership and project management are also central to the responsibilities of a Certified Quality Engineer. CQEs must guide cross-functional teams, manage quality improvement initiatives, and influence organizational culture. Effective leadership involves motivating team members, fostering collaboration, and ensuring that quality objectives are integrated with broader strategic goals. In addition, project management skills, including planning, resource allocation, risk assessment, and performance tracking, allow CQEs to implement initiatives efficiently and deliver measurable outcomes. The combination of leadership and technical expertise positions them as both advisors and implementers, capable of driving meaningful change across an organization.

Integration of quality systems is another critical aspect of the CQE’s responsibilities. Professionals in this role must understand how various quality processes interact with operational, production, and supply chain functions. By evaluating existing systems, identifying redundancies or gaps, and recommending process enhancements, CQEs ensure that quality initiatives are coherent and aligned with organizational strategy. This systems-level perspective allows engineers to optimize workflows, reduce inefficiencies, and improve overall performance, reinforcing the strategic importance of quality management within the enterprise.

Continuous improvement is foundational to quality engineering. CQEs apply methodologies such as Lean, Six Sigma, and Total Quality Management to enhance process efficiency and product reliability. Through root cause analysis, process mapping, and implementation of improvement strategies, they systematically reduce defects, eliminate waste, and optimize resource utilization. This commitment to ongoing enhancement ensures that organizations remain competitive, responsive to customer needs, and capable of maintaining consistently high-quality outputs. Mastery of these methodologies is also a core component of the CQE certification, demonstrating the engineer’s ability to translate theory into practical, effective solutions.

Supplier and customer quality management further highlight the breadth of the CQE role. Engineers evaluate supplier performance, conduct audits, and implement quality agreements to ensure that incoming materials meet required standards. Similarly, they analyze customer feedback, identify areas for improvement, and take corrective actions to enhance satisfaction. This dual focus on internal and external quality enables organizations to deliver products and services that consistently meet expectations, reinforcing the importance of CQEs in maintaining both operational integrity and customer trust.

Ethical practice and professional responsibility underpin every aspect of the CQE function. Engineers are expected to act with integrity, transparency, and accountability, ensuring that their recommendations and reports reflect accurate assessments and unbiased evaluations. Adhering to ethical standards not only supports compliance with legal and regulatory requirements but also enhances credibility and trust across the organization. Ethical decision-making is particularly important when conducting audits, implementing corrective actions, or influencing quality-related decisions, emphasizing the professional rigor expected of certified quality engineers.

Preparation for the CQE examination requires comprehensive understanding of the Body of Knowledge, which encompasses statistical methods, quality management systems, product and process design, leadership, and continuous improvement practices. Candidates must demonstrate both theoretical knowledge and practical competence, reflecting the expectations of professional practice. Structured study, hands-on application, and consistent self-assessment ensure readiness for the exam while reinforcing the real-world skills necessary for effective quality engineering.

In addition to technical and analytical expertise, CQEs contribute to organizational growth through risk management and proactive problem-solving. By identifying potential points of failure and implementing mitigation strategies, they safeguard process reliability and enhance organizational resilience. This proactive approach not only reduces operational disruptions but also strengthens the organization’s ability to respond to changing regulatory, market, or operational conditions.

Certification as a CQE signifies a commitment to excellence in quality engineering. It validates that professionals possess the knowledge, skills, and ethical grounding necessary to implement effective quality systems and drive continuous improvement. Recognized nationally and internationally, the certification enhances professional credibility, supports career advancement, and demonstrates the value of the certified engineer to employers, colleagues, and clients.

Through their combination of technical acumen, leadership capabilities, and commitment to ethical practice, Certified Quality Engineers play a central role in shaping organizational success. They ensure that processes are efficient, products are reliable, and quality objectives align with strategic business goals. By integrating data-driven decision-making, continuous improvement, and systems thinking into their practice, CQEs provide lasting value, helping organizations achieve sustainable performance, regulatory compliance, and customer satisfaction. The CQE credential thus reflects not only professional knowledge but also the ability to apply that knowledge to create measurable impact, positioning certified quality engineers as essential contributors to operational excellence and long-term organizational growth.

ASQ CQE practice test questions and answers, training course, study guide are uploaded in ETE Files format by real users. Study and Pass CQE Certified Quality Engineer certification exam dumps & practice test questions and answers are to help students.

Exam Comments * The most recent comment are on top

Purchase CQE Exam Training Products Individually

Why customers love us?

What do our customers say?

The resources provided for the ASQ certification exam were exceptional. The exam dumps and video courses offered clear and concise explanations of each topic. I felt thoroughly prepared for the CQE test and passed with ease.

Studying for the ASQ certification exam was a breeze with the comprehensive materials from this site. The detailed study guides and accurate exam dumps helped me understand every concept. I aced the CQE exam on my first try!

I was impressed with the quality of the CQE preparation materials for the ASQ certification exam. The video courses were engaging, and the study guides covered all the essential topics. These resources made a significant difference in my study routine and overall performance. I went into the exam feeling confident and well-prepared.

The CQE materials for the ASQ certification exam were invaluable. They provided detailed, concise explanations for each topic, helping me grasp the entire syllabus. After studying with these resources, I was able to tackle the final test questions confidently and successfully.

Thanks to the comprehensive study guides and video courses, I aced the CQE exam. The exam dumps were spot on and helped me understand the types of questions to expect. The certification exam was much less intimidating thanks to their excellent prep materials. So, I highly recommend their services for anyone preparing for this certification exam.

Achieving my ASQ certification was a seamless experience. The detailed study guide and practice questions ensured I was fully prepared for CQE. The customer support was responsive and helpful throughout my journey. Highly recommend their services for anyone preparing for their certification test.

I couldn't be happier with my certification results! The study materials were comprehensive and easy to understand, making my preparation for the CQE stress-free. Using these resources, I was able to pass my exam on the first attempt. They are a must-have for anyone serious about advancing their career.

The practice exams were incredibly helpful in familiarizing me with the actual test format. I felt confident and well-prepared going into my CQE certification exam. The support and guidance provided were top-notch. I couldn't have obtained my ASQ certification without these amazing tools!

The materials provided for the CQE were comprehensive and very well-structured. The practice tests were particularly useful in building my confidence and understanding the exam format. After using these materials, I felt well-prepared and was able to solve all the questions on the final test with ease. Passing the certification exam was a huge relief! I feel much more competent in my role. Thank you!

The certification prep was excellent. The content was up-to-date and aligned perfectly with the exam requirements. I appreciated the clear explanations and real-world examples that made complex topics easier to grasp. I passed CQE successfully. It was a game-changer for my career in IT!

I am looking for the free sample CQE exam questions.

Thanks,

Ali